Drive unit for hoist

A driving device, elevator technology, applied in the direction of hoisting device, transportation and packaging, spring mechanism, etc., to achieve the effect of reducing the length of the structure, reducing the cost, and reducing the length of the drive shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Detailed Description of Preferred Embodiments

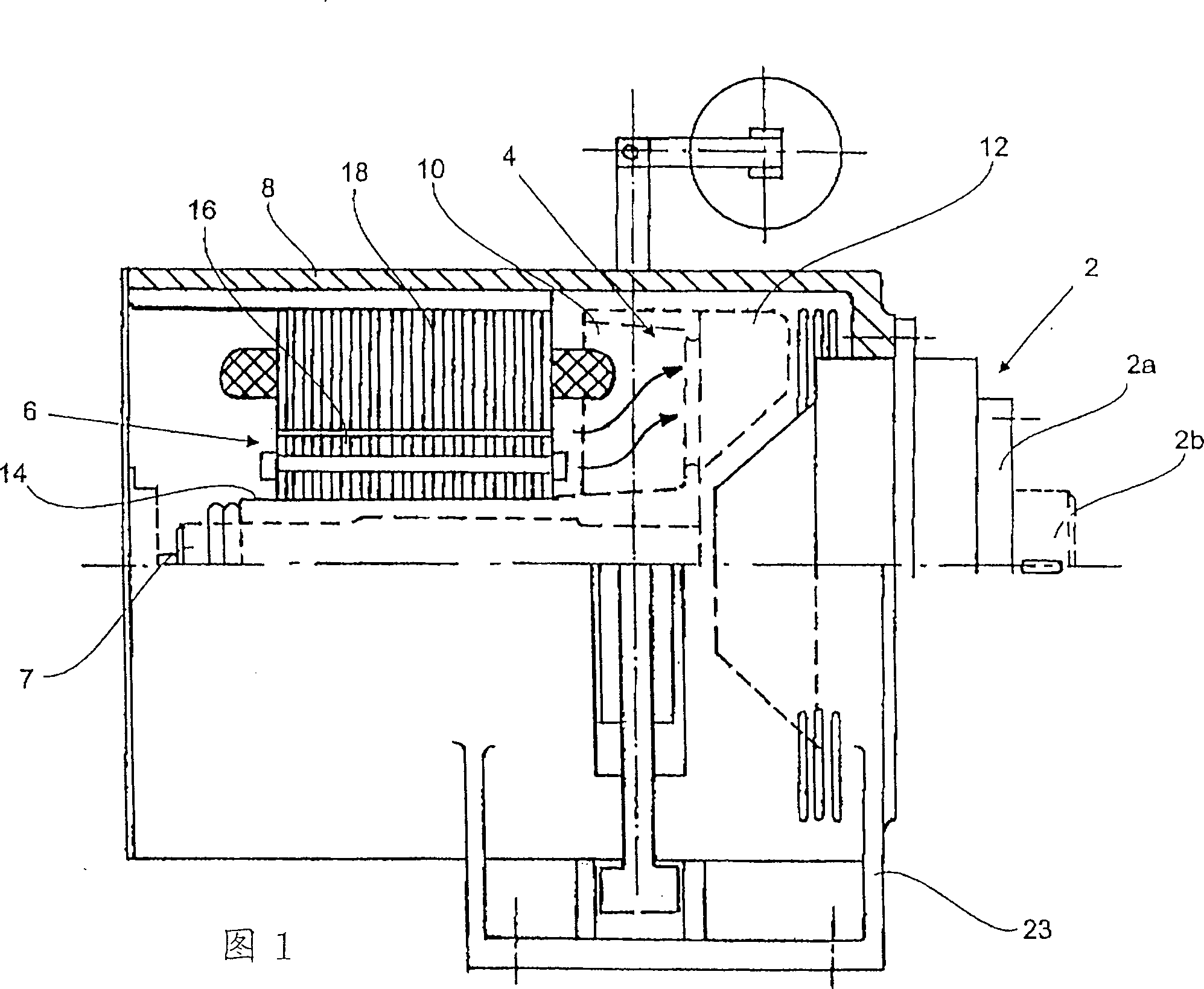

[0017] FIG. 1 is a schematic diagram of a driving device of an elevator. The basic components include a transmission device 2 , a brake 4 and a motor 6 , which are coaxially mounted on a drive shaft 7 . The casing 8 contains the brake 4, the motor 6 and a part of the transmission device, and carries an elevator cable drive disc (not shown in the figure). The casing 8 is anchored on a foundation (not shown). The drive disk can be supported or mounted on the drive flange 2a or on the drive shaft 2b.

[0018] Described brake 4 has the brake body 10 of a cast brake drum shape, is provided with the rotor bushing 14 of the rotor 16 of ventilation vane 12 and described motor 6 (having rotor 16 and stator 18) on it (see also Figure 3a ). The stator winding is coupled with the brake drum 4 (used as a motor output), and the brake drum, for example, can be provided with vents 19 on the axially outer surface of the brake drum ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com