Fast and uniform dilution device for polymer concentrated solution

A dilution device and high polymer technology, which is applied in the field of rapid and uniform dilution of high polymer concentrated solution, can solve the problems of increasing the load of the aircraft, not being suitable for drag reduction, and being unable to carry a large amount of high polymer dilute solution, etc., to achieve the goal of quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

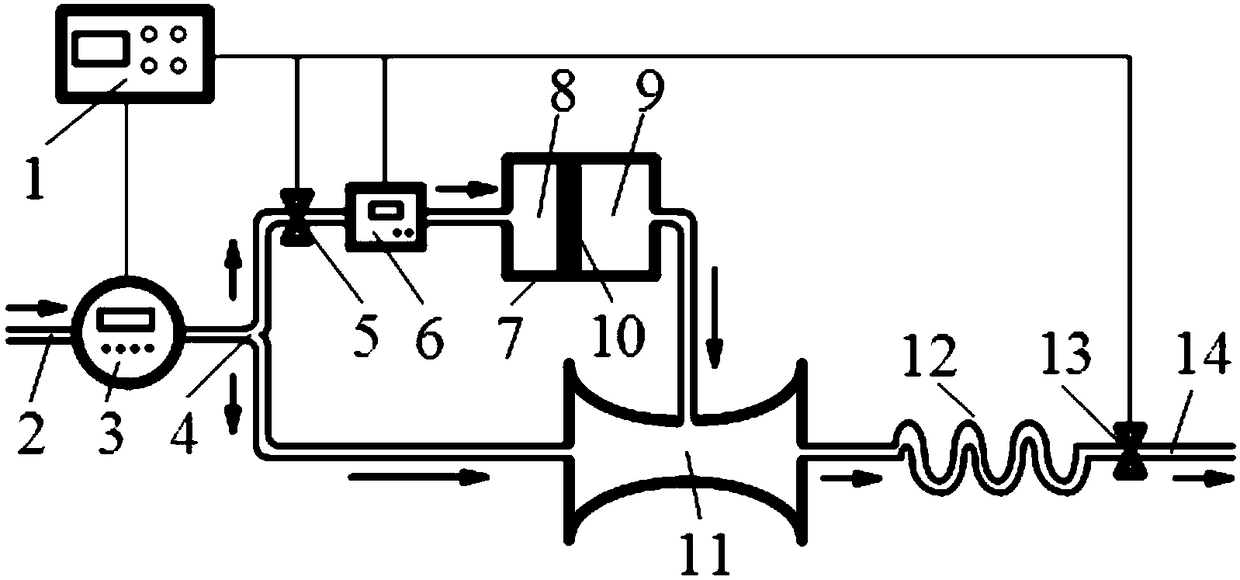

[0022] This embodiment is a device for rapid and uniform dilution of high polymer concentrated solution.

[0023] refer to figure 1 , the high polymer concentrated solution rapid and uniform dilution device in this embodiment, when the controller 1 obtains the external dilution command, calculates according to the injection rate and concentration requirements of the required high polymer dilute solution, and outputs the corresponding signal. The high polymer concentrated solution rapid and uniform dilution device consists of a controller 1, a water diversion pipe 2, a metering pump 3, a branch pipe 4, an electric valve 5, an electromagnetic flowmeter 6, a storage chamber 8, an upstream chamber 9, a downstream chamber 10, a mixing chamber Section 11, elbow section 12, solenoid valve 13, output pipe. After the controller 1 receives the external dilution command, it outputs a control signal, and each component automatically starts and adjusts after receiving the corresponding si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com