Floating puffed compound feed for frogs at adult frog stage and preparation method of floating puffed compound feed

A technology of expanding compound feed and growing frogs, which is applied in the field of feed, can solve the problems of feed palatability and growth-promoting effect, and achieve the effects of promoting healthy and rapid growth, high feed conversion rate, and improving stability and palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

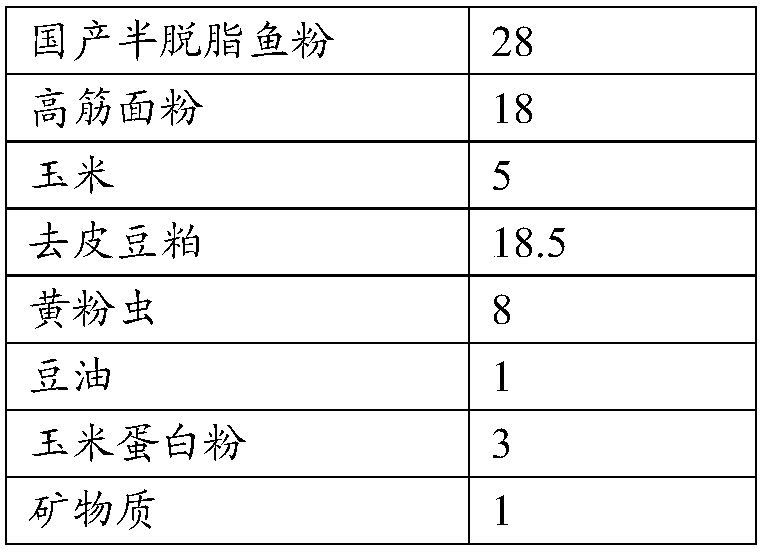

[0033] The formulation (parts by weight) of the buoyant puffed compound feed of the frog in the frog-growing stage of the present embodiment is as shown in Table 2 below.

[0034] Table 2

[0035]

[0036]

[0037] According to the above formula, the buoyant puffed compound feed for the frog adult stage was prepared. The feed product particles were uniform, the floating rate reached 100%, and the floating time could reach more than 6 hours, and there was no crack after 20 days of feeding tests. Adult frogs are active in feeding (eat within 30 minutes), have a natural body color, a feed coefficient of 1.17, a survival rate of 99%, low morbidity, and fast average daily growth rate and weight gain.

Embodiment 2

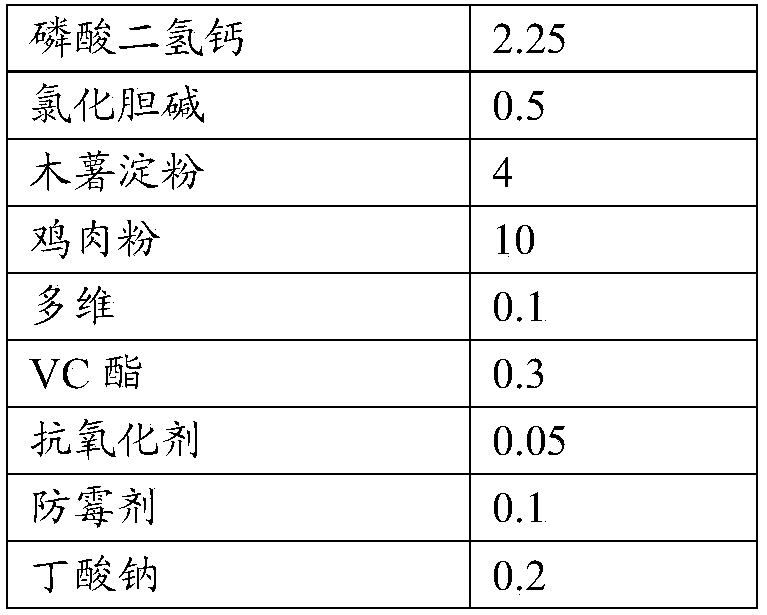

[0039] The formula (parts by weight) of the buoyant puffed compound feed for the frog adult stage of the frog in this embodiment is as shown in Table 3 below.

[0040] table 3

[0041] Domestic semi-skimmed fish meal

[0042] According to the above formula, the buoyant puffed compound feed for the frog adult stage is prepared. The feed product particles are uniform, the floating rate is 100%, the floating time can reach more than 6 hours, and there is no crack after 20 days of feeding tests. Adult frogs are active in feeding (eat within 30 minutes), have a natural body color, a feed coefficient of 1.13, a survival rate of 100%, a low morbidity rate, and a fast average daily growth rate and weight gain.

Embodiment 3

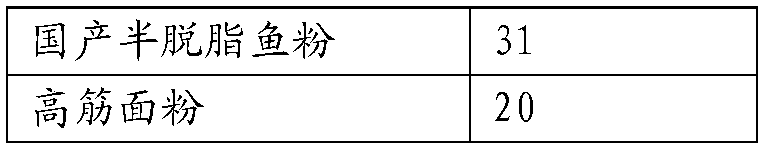

[0044] The formulation (parts by weight) of the buoyant puffed compound feed for the frog adult stage of the frog in this embodiment is as shown in Table 4 below.

[0045] Table 4

[0046] Domestic semi-skimmed fish meal

[0047] According to the above formula, the buoyant puffed compound feed for the frog adult stage is prepared. The feed product particles are uniform, the floating rate is 100%, the floating time can reach more than 6 hours, and there is no crack after 20 days of feeding tests. Adult frogs are active in feeding (eat within 35 minutes), have a natural body color, a feed coefficient of 1.21, a survival rate of 98%, a low incidence rate, and a fast average daily growth rate and weight gain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com