Image sensor and manufacturing method thereof

A technology of an image sensor and a manufacturing method, which is applied to semiconductor devices, electric solid-state devices, radiation control devices, etc., can solve the problems of electron overflow, easy saturation of white light pixels, and degradation of image quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

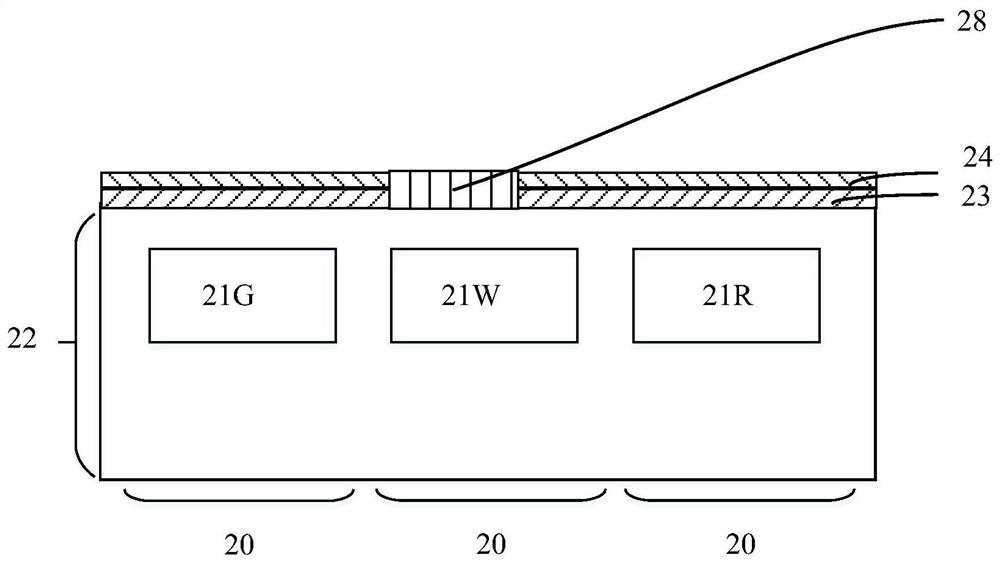

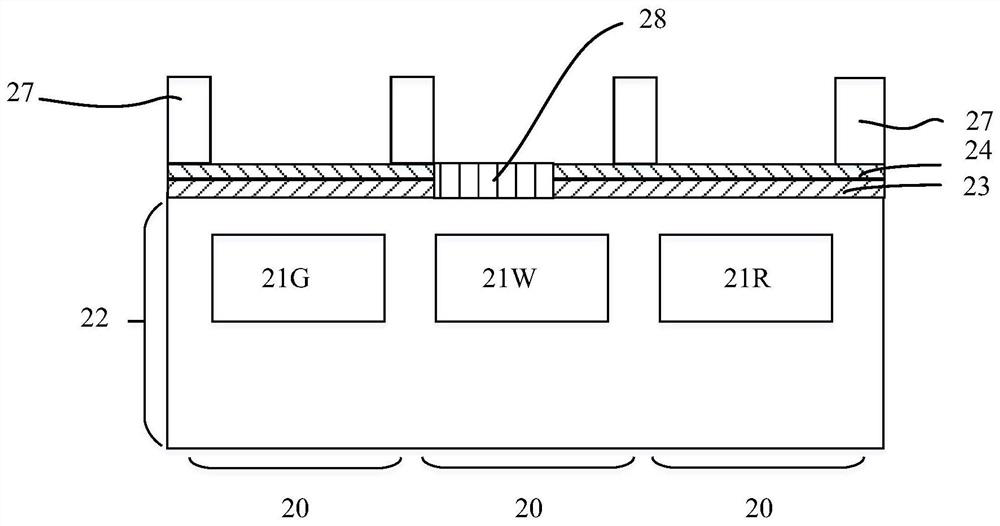

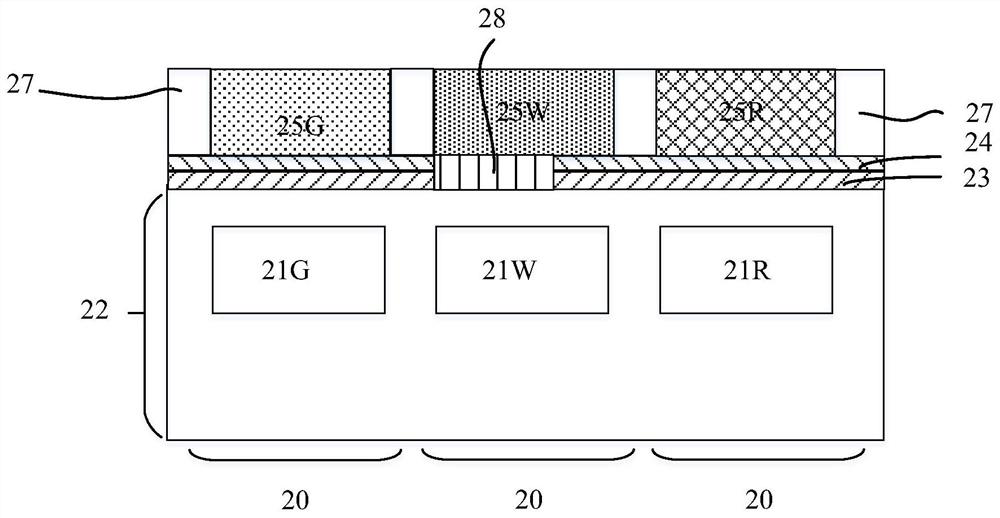

[0021] The manufacturing method of the image sensor in this embodiment includes: providing a semiconductor substrate 22 formed with a photodiode 21, the semiconductor substrate 22 includes different pixel regions 20, and the pixel region 20 includes a white pixel region; form an insulating structure on the insulating structure; form an organic photodiode 28 that penetrates the insulating structure and partially covers the white pixel region 20; forms a light-shielding film 27 that partially covers the insulating structure on the insulating structure; forms on the insulating structure Corresponding to the color filter layer 25 of different pixels, the color filter layer 25 includes a white color filter layer 25W, and the light-shielding film isolates the color filter layer 25 of the different pixels; it is formed above the color filter layer 25 at the corresponding position of each pixel area microlens26.

[0022] refer to figure 1 , first provide a semiconductor substrate 22...

Embodiment 2

[0045] refer to Figure 4 , In another embodiment of the present invention, another image sensor structure is provided, including: a semiconductor substrate 22 formed with photodiodes, the semiconductor substrate 22 includes different pixel regions 20, wherein the photodiodes correspond to different The pixel area includes a white pixel area; an insulating structure located on the semiconductor substrate; an organic photodiode 28 that penetrates through the insulating structure and partially covers the photodiode of the white pixel area; A light-shielding film 27 on the insulating structure and partially covering the insulating structure, the light-shielding film 27 isolating the different pixel regions 20; a color filter layer 25 corresponding to different pixels on the insulating structure, the color filter layer includes a white filter a color layer, the light-shielding film isolating the color filter layers of different pixels; and a microlens 26 located above the color fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com