Industrial level control cabinet and system safety control method thereof

A technology of system security and control method, which is applied in the field of industrial control cabinet and its system security control, can solve the problems of system redundancy and high cost, and achieve the effect of clear function, convenient maintenance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

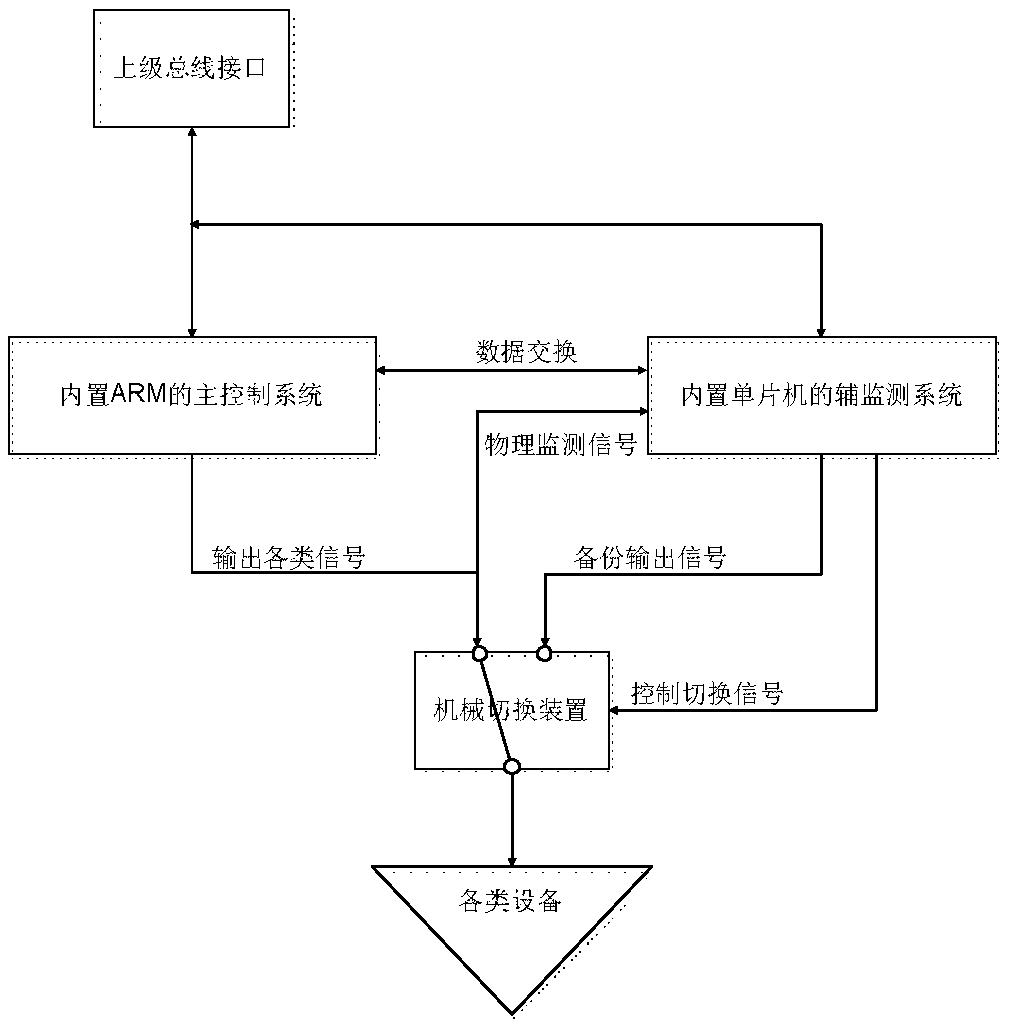

[0027] An industrial-grade control cabinet, including a main control system 2, an auxiliary monitoring system 3 and a mechanical switching device 4, the main control system 2 and the auxiliary monitoring system 3 are connected to the same upper-level bus interface (not shown) that can exchange information with the upper-level controller 1 As shown in the figure), the main control system 2 and the auxiliary monitoring system 3 are both connected to the mechanical switching device 4, and the mechanical switching device 4 is connected to various equipment. Connect with main control system 2.

[0028] The main control system needs to realize many functions, so ARM is used, and the model can be STR710F. The auxiliary monitoring system only needs to realize data communication with the main control system, read the output signal of the main control system and store the preset signal, so adopt It can be realized by single-chip microcomputer, and the model can adopt 89C51 single-chip m...

Embodiment 2

[0034] A system security control method for an industrial-grade control cabinet, comprising the following steps:

[0035] Both the main control system and the auxiliary monitoring system obtain the same upper-level controller information through the upper-level bus interface. The auxiliary monitoring system performs physical monitoring of various signals output by the main control system in real time, and at the same time can perform data interaction with the main control system to obtain the main control system. The output signal of the system is backed up as a backup output signal;

[0036] The auxiliary monitoring system has an output safety value mode and a preset mode. The output safety value mode is an application mode in which the operation of the main control module ARM is normal, but the output signal is abnormal; the preset mode is the main core ARM of the main control system with built-in ARM Application mode of fixed signal without dynamic adjustment in fault state...

Embodiment 3

[0040] A system security control method for an industrial-grade control cabinet, comprising the following steps:

[0041] Both the main control system and the auxiliary monitoring system obtain the same upper-level controller information through the upper-level bus interface. The auxiliary monitoring system performs physical monitoring of various signals output by the main control system in real time, and can perform data interaction with the main control system at the same time to obtain the main control system. The output signal of the system is backed up as a backup output signal;

[0042] The auxiliary monitoring system has an output safety value mode and a preset mode. The output safety value mode is an application mode in which the operation of the main control module ARM is normal, but the output signal is abnormal; the preset mode is the main core ARM of the main control system with built-in ARM Application mode of fixed signal without dynamic adjustment in fault state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com