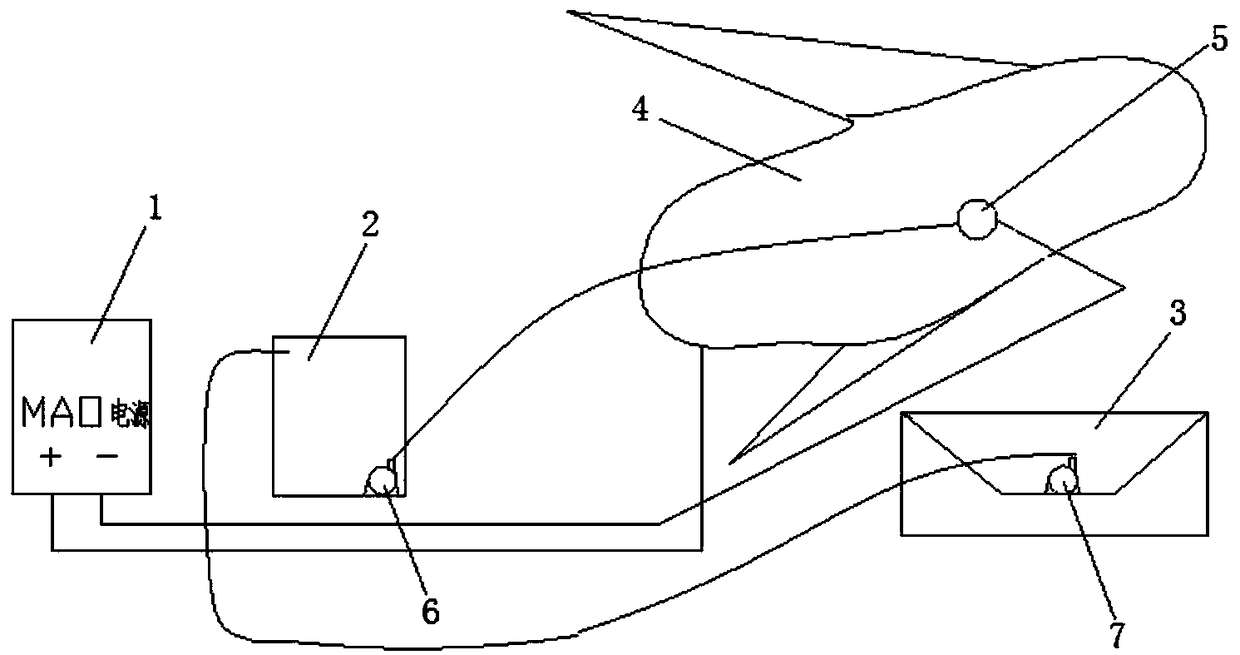

Local corrosion-resistant scanning type micro-arc oxidation treatment process and device for shipboard aircraft

A technology of micro-arc oxidation and treatment process, which is applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc. It can solve the problems of secondary damage to components, complicated disassembly and assembly procedures, and large shape of mechanical parts of carrier-based aircraft. Simple operation, improved repair efficiency, and reduced repair difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment is an embodiment of repairing a part, and it is required to form a micro-arc oxidation ceramic layer with a thickness of 5 μm on the surface of the part to be repaired. The content of each component in the electrolyte solution in this embodiment is respectively:

[0054] Sodium phosphate is 30g / L; sodium silicate is 2g / L; titanium potassium oxalate is 3g / L, and the rest is tap water. Stir evenly and leave for 12 hours to obtain an electrolyte.

[0055] In this embodiment, the micro-arc oxidation power supply adopts a constant voltage mode, and the electrical parameters (aluminum alloy) are set as:

[0056] The voltage is 550V, the duty cycle is 3%, the frequency is 1000Hz, and the oxidation time is 5min.

Embodiment 2

[0058] This embodiment is an embodiment of repairing a part, and it is required to form a micro-arc oxidation ceramic layer with a thickness of 25 μm on the surface of the part to be repaired. The content of each component in the electrolyte solution in this embodiment is respectively:

[0059] Potassium phosphate is 35g / L; sodium silicate is 10g / L; potassium fluotitanate is 3g / L, and the rest is tap water. Stir evenly and leave for 12 hours to obtain an electrolyte.

[0060] In this embodiment, the micro-arc oxidation power supply adopts a constant voltage mode, and the electrical parameters (aluminum alloy) are set as:

[0061] The voltage is 600V, the duty cycle is 5%, the frequency is 500Hz, and the oxidation time is 35min.

Embodiment 3

[0063] This embodiment is an embodiment of repairing a part, and it is required to form a micro-arc oxidation ceramic layer with a thickness of 50 μm on the surface of the part to be repaired. The content of each component in the electrolyte solution in this embodiment is respectively:

[0064] Potassium phosphate 35g / L; Potassium silicate 10g / L; Potassium fluotitanate 5g / L, and tap water as the rest, stirred evenly, and left for 12 hours to obtain an electrolyte.

[0065] In this embodiment, the micro-arc oxidation power supply adopts a constant voltage mode, and the electrical parameters (aluminum alloy) are set as:

[0066] The voltage is 600V, the duty cycle is 10%, the frequency is 600Hz, and the oxidation time is 100min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com