Grinding device for welding operation

A welding machine and grinding machine technology, which is applied to grinding machines, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of low production efficiency, inability to achieve continuous production, and high labor costs, and achieve high work efficiency. The effect of saving manpower and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

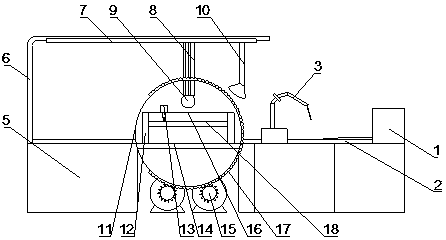

[0025] A grinding device for welding operation, comprising a plate turning machine, a welding machine is provided on one side of the plate turning machine, and a grinding machine is provided on the other side.

[0026] One side of the welding machine is provided with a welding manipulator 3, the top of the welding machine is provided with a plate track 2, and the end of the plate track 2 away from the turning machine is provided with a propeller 1, and both sides of the plate track 2 are provided with fixing clips 4 above the other end.

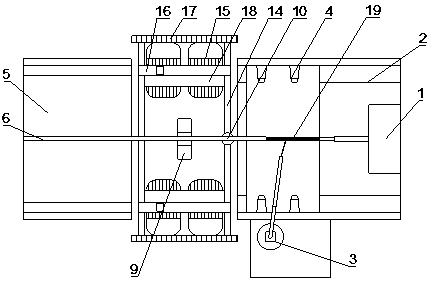

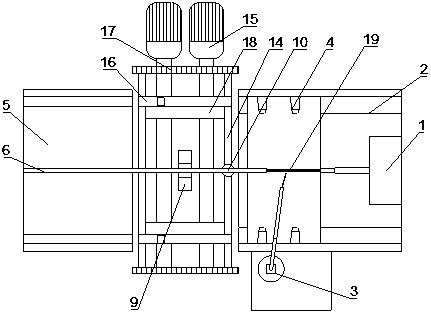

[0027] The grinding machine includes a storage table 5, on which a "┌" type frame 6 is fixed, a grinding track 7 is arranged below the crossbeam of the frame 6, and a vertically downward grinding cylinder 8 is arranged below the grinding track 7. A grinding wheel 9 is provided below the cylinder 8 . An air supply device 10 is slid on the frame 6 of the grinding machine, and the air outlet of the air supply device 10 faces the plate turning ma...

Embodiment 2

[0032] The difference from Embodiment 1 is that there are two overturning motors 15 arranged at the bottom of the turning machine, and two gears are arranged on the rotating shaft of each overturning motor 15, and the two gears are connected with the two overturning discs 11 respectively. The chain groove engagement of the two turning discs 11 can be ensured to turn over synchronously and at the same angle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com