Cylindrical battery peeling mechanism for cooperating with robot to work

A cylindrical battery and robot technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of large battery capacity, battery damage, low efficiency, etc., and achieve the effect of improving peeling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

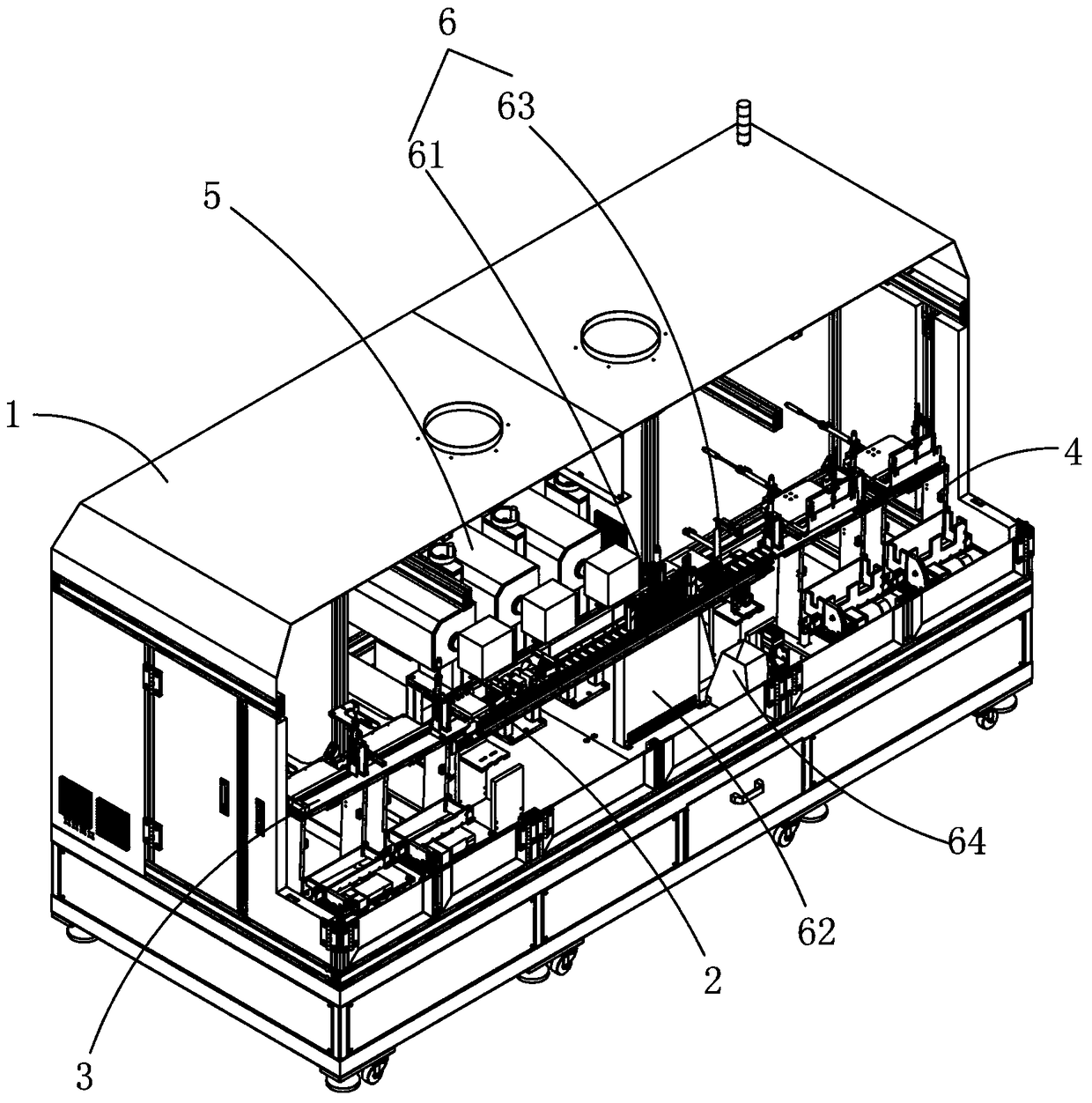

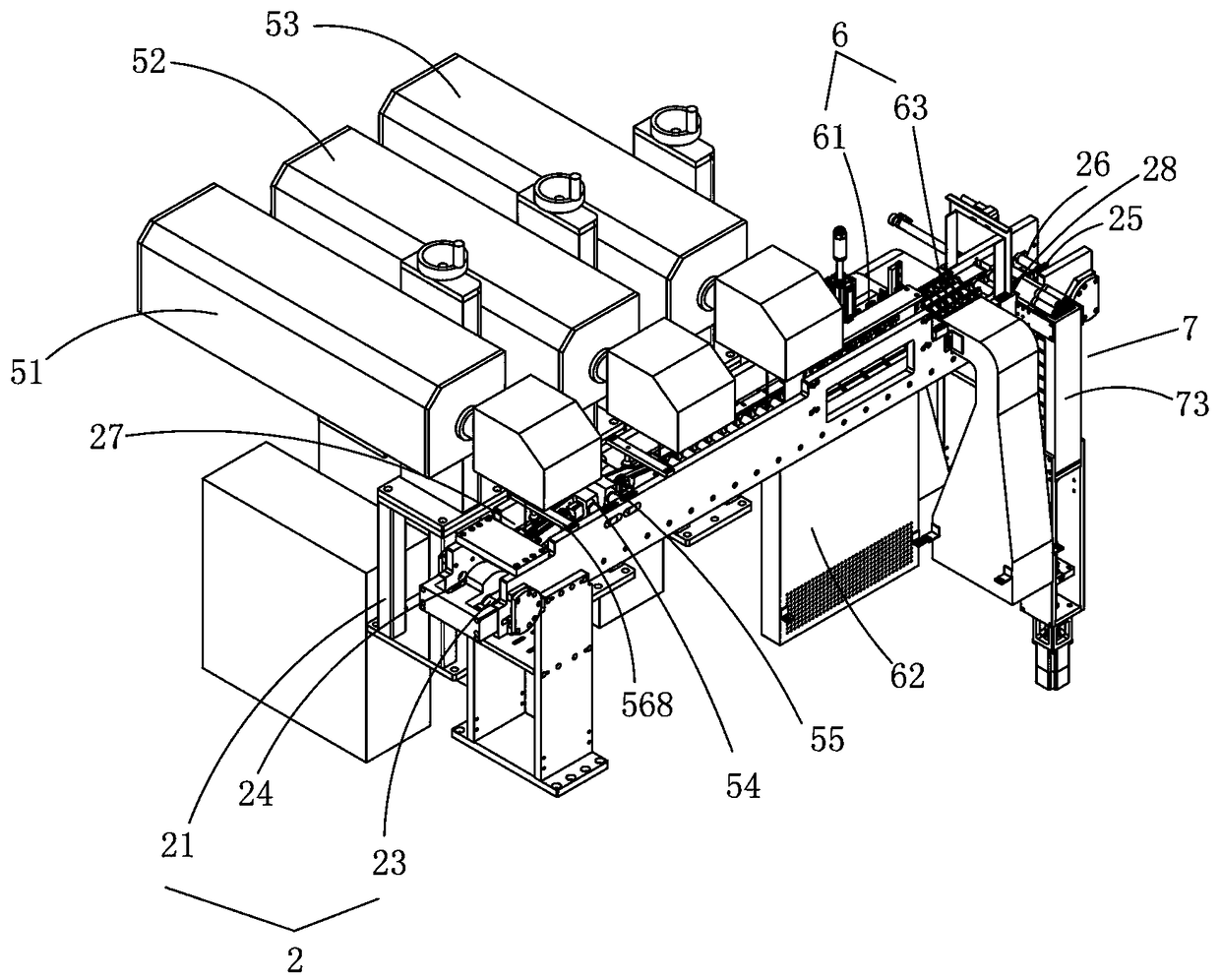

[0031] Example, combined with Figures 1 to 9As shown, a cylindrical battery peeling mechanism that cooperates with robots includes a chassis 1, a battery transport device 2 for transporting batteries is provided in the chassis 1, and a battery feeding device 3 is provided at the entrance of the battery transport device 2. The battery unloading device 4 at the exit of the battery transport device 2, and along the battery transport device 2 are sequentially provided with a laser cutting device 5 for cutting the battery skin, a battery rubbing device 6 for peeling off the battery skin, and a battery rubbing device 6 for recycling defective products. The defective product recycling device 7.

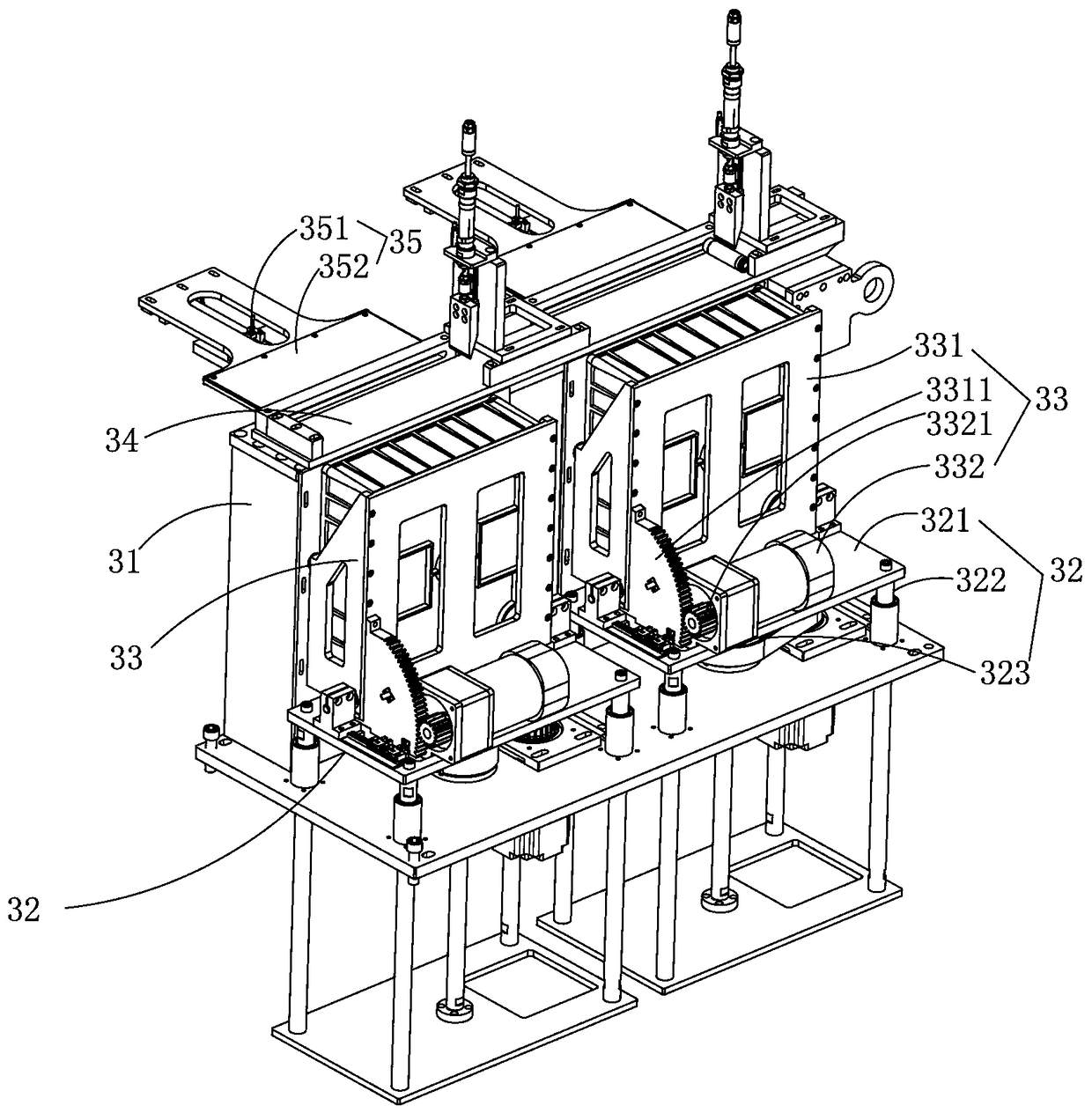

[0032] The battery feeding device 3 includes a machine tool 31 , a lifting platform assembly 32 , an overturning bin assembly 33 , a battery placement track 34 and a battery clamping assembly 35 . The battery placement track 34 is arranged on the machine tool 31, and the lifting platform a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com