Electric wire skinning yarn-shearing machine

A yarn cutting machine and electric wire technology, applied in the direction of circuits, electrical components, circuit/collector components, etc., can solve the problems of low efficiency and high cost of peeling work, and achieve the effect of reducing production costs and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Attached below figure 1 to attach Figure 8 The present invention is described further:

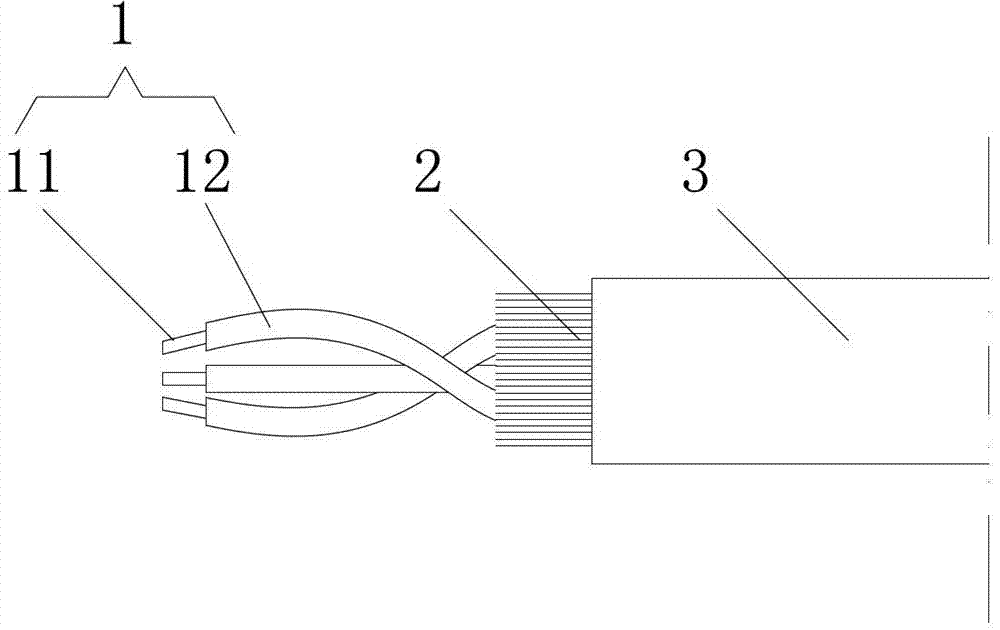

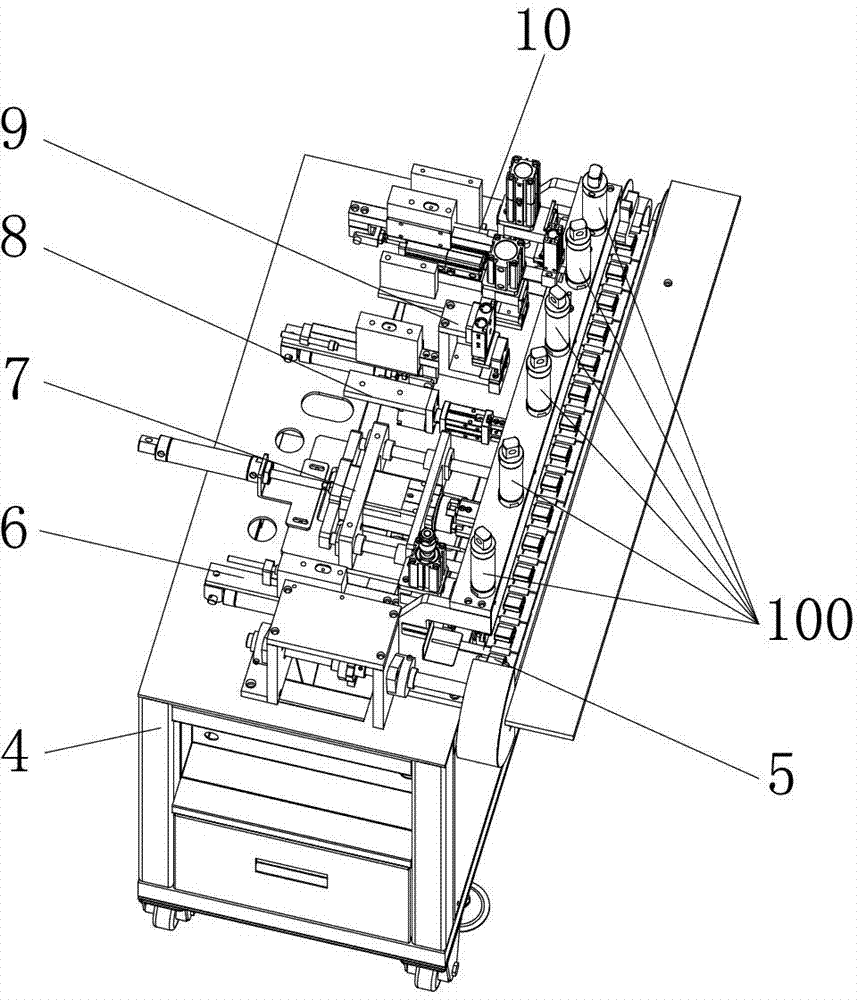

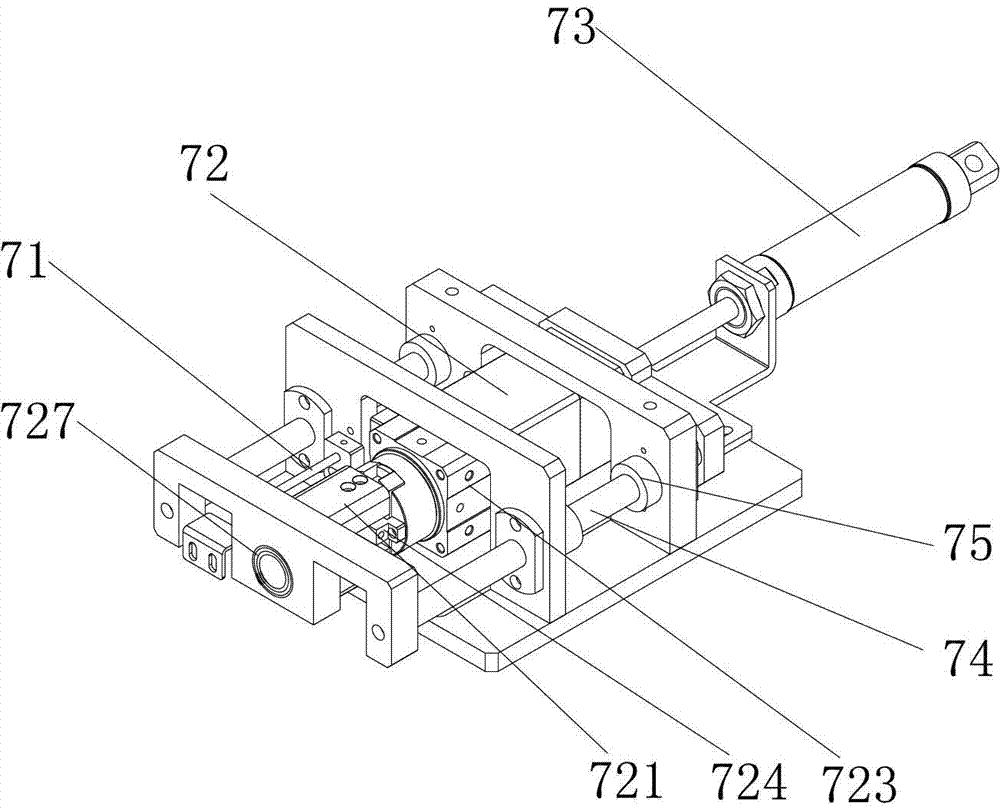

[0028] Such as figure 2 Shown a kind of electric wire peeling yarn cutting machine, comprises machine platform 4, is provided with a conveying device 5 on machine platform 4, is provided with the peeling device 6 that removes electric wire outer sheath 3 successively on the conveying direction of conveying device 5, The yarn removing device 7 for cutting off the yarn 2 in the electric wire, the anti-twisting device 8 for twisting the twisted multi-strand bent core wire 1 into a straight core wire 1, and the device for smoothing the multi-strand core wire 1 Straightening device 9 and stripping device 10 for removing the insulating layer 12 on the core wire 1.

[0029] At present, there are relevant patents or patent applications for the transmission device 5 of the electric wire, the peeling device 6 of the electric wire, and the peeling device 10 for removing the insulating lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com