A fully automatic orange peeling machine

A peeling machine, fully automatic technology, applied in the fields of vegetable or fruit peeling, food science, application, etc., can solve the problems of inability to guarantee peeling of oranges, low efficiency, and many defective products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

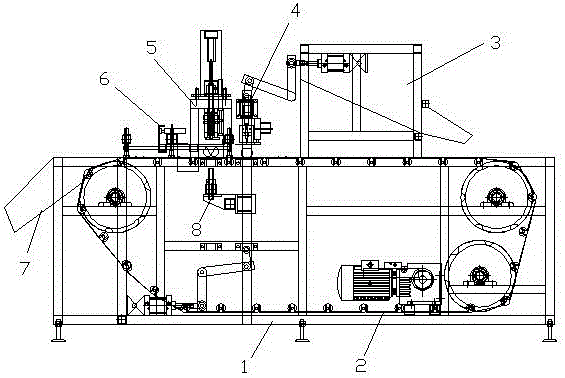

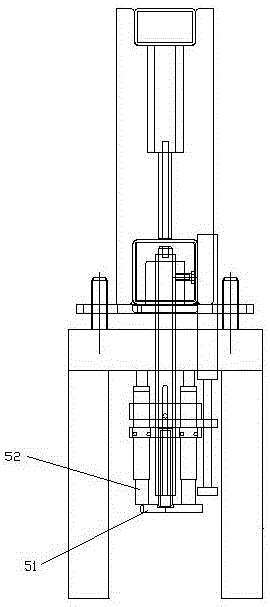

[0020] Such as Figure 1-Figure 4 Shown, a kind of full-automatic orange peeling machine comprises frame 1, and described frame 1 is provided with conveying chain plate 2, and described conveying chain plate 2 is equidistantly provided with a plurality of orange placement holes, and described frame The end of 1 is provided with a discharge port 7, the top of the conveying chain plate 2 is provided with a flap opening device 4, and the top of the conveying chain plate 2 between the flap opening device 4 and the discharge port 7 is also provided with a pulp gripper. Take device 5.

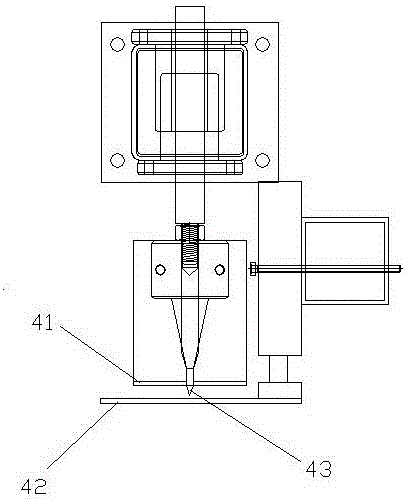

[0021] In this embodiment, the flap opening device 4 includes a pressing plate 42 that can move up and down for fixing oranges, and a trident cutter 41 that can move up and down and pass through the pressing plate 42 is arranged above the pressing plate 42. When the oranges reach the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com