Upward pressing type machine clamp transposition turning tool teaching aid based on 3D printing

A 3D printing and machine clamping technology, which is applied in the direction of cutting tools for lathes, turning equipment, manufacturing tools, etc., can solve the problems of low strength, unreliable connection of components, and less cross-section information, and achieve high strength, low price, The effect of firm assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

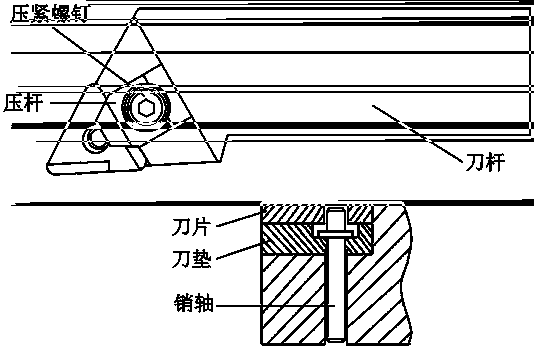

[0016] The device of this implementation example includes a tool holder, a blade, a cutter shim, a pin shaft, a compression screw, a pressing plate part and an indexable turning tool assembly model of an upper pressing machine clamp, such as figure 1 shown. On the premise that the 3D printed parts meet the assembly accuracy, use the pin to press the tool shim on the tool holder, then position the blade above the tool shim, and press the blade on the tool shim through the pressure plate and the pressing screw to complete the upper pressing An indexable turning tool assembly with a machine clamp, showing its composition and structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com