Automatic feeding device for fish farming pond

A technology for fish ponds and equipment, applied in fish farming, climate change adaptation, applications, etc., can solve problems such as motor burnout, user economic loss, fish electrocution, etc., and achieve the effect of avoiding feed blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

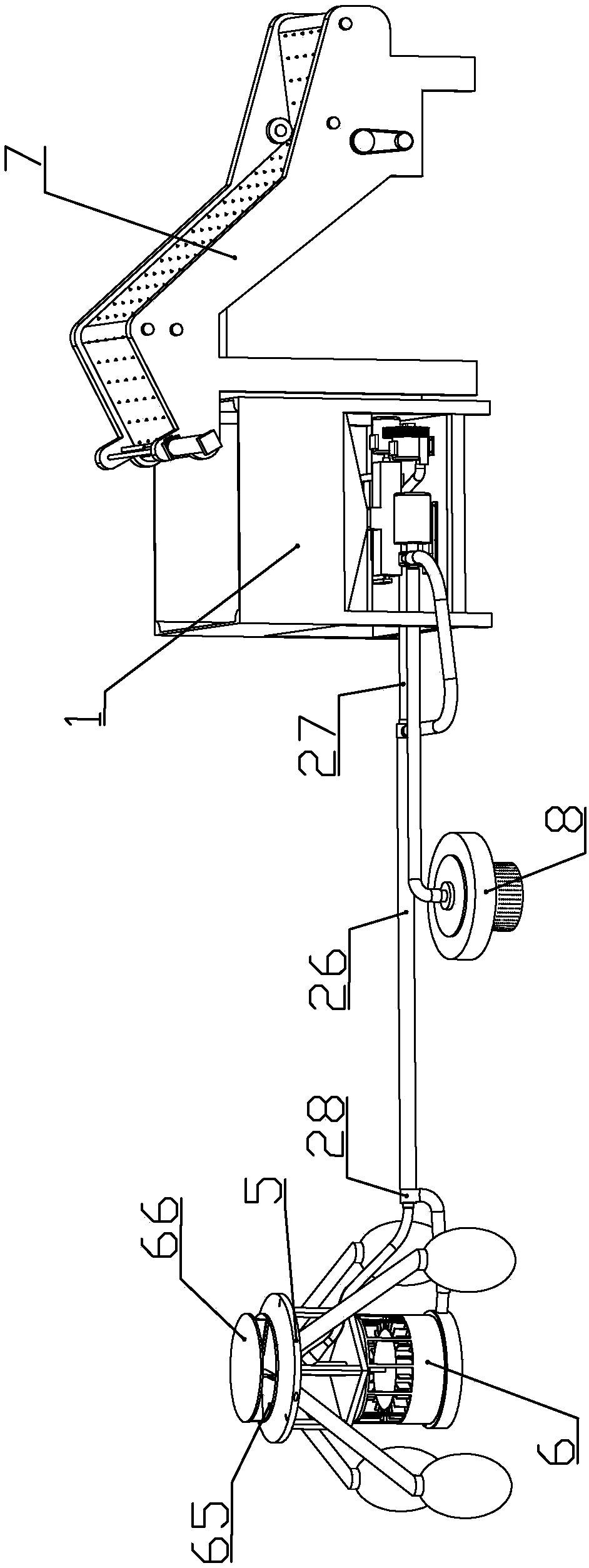

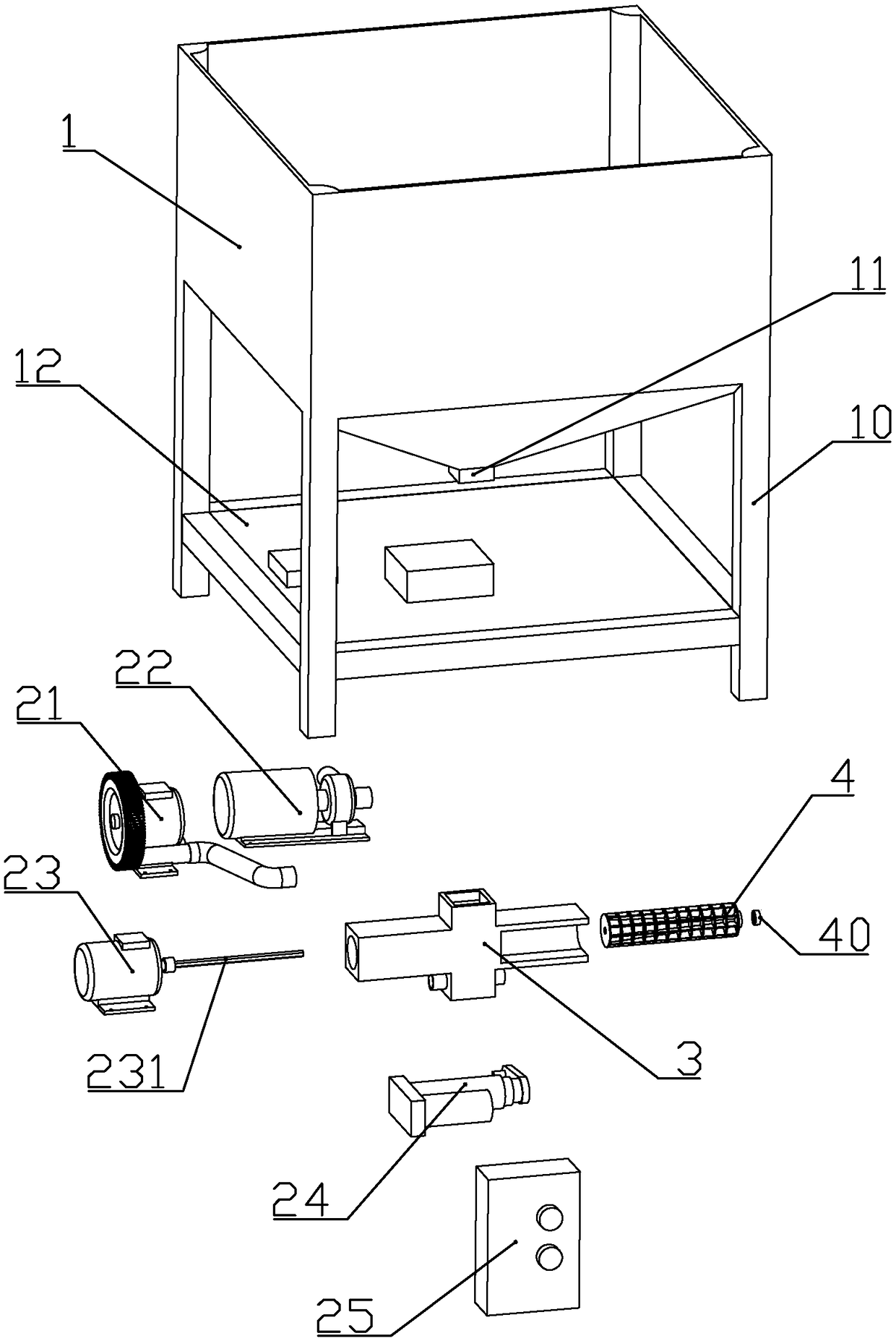

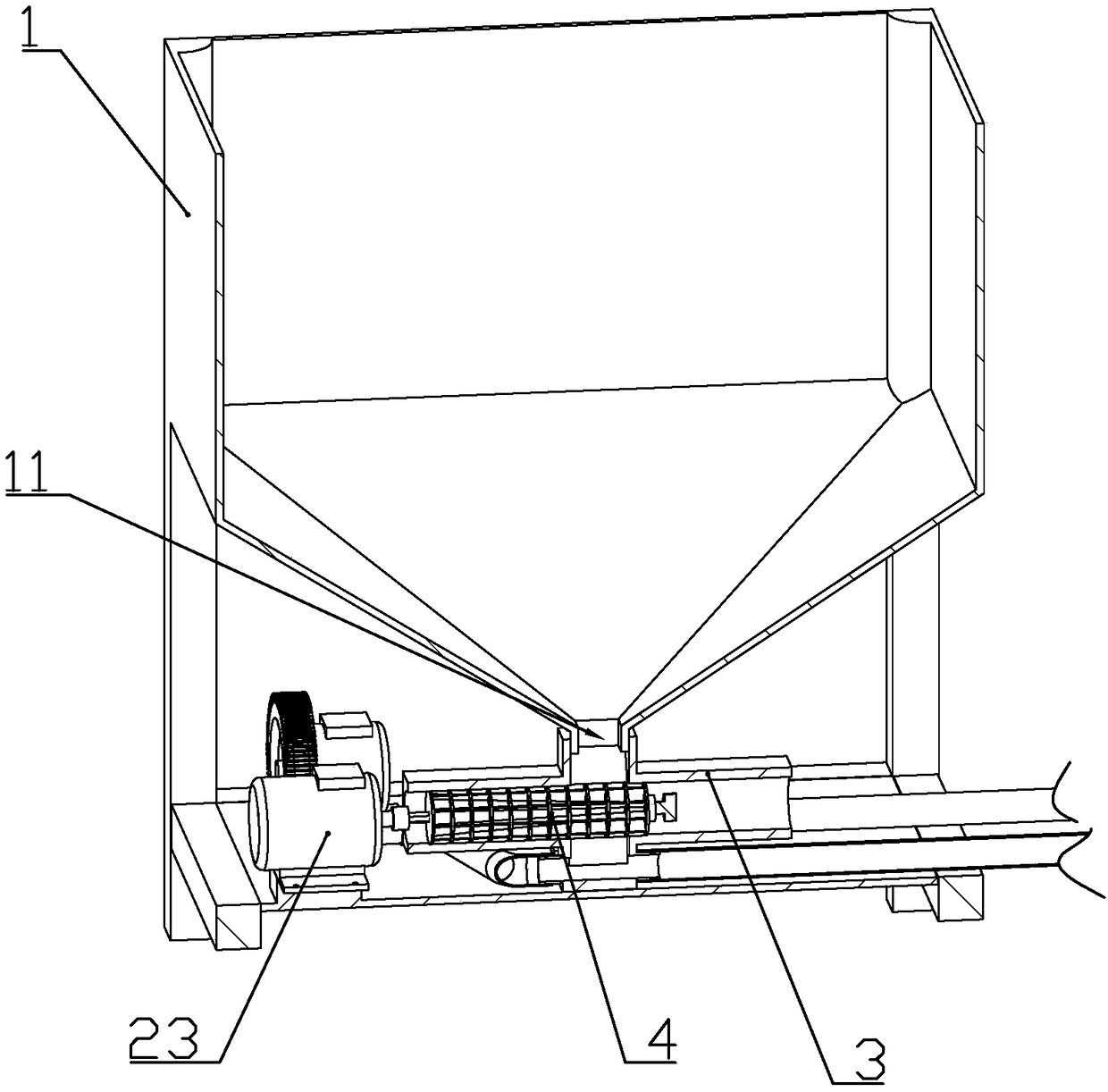

[0069] according to Figure 1 to Figure 16 As shown, the automatic bait feeding equipment for aquaculture fish ponds described in this embodiment includes a material storage component located in a feed warehouse adjacent to the fish pond, and a throwing component floating on the water surface of the fish pond.

[0070] The material storage assembly includes a bracket 10 and an inverted pyramid-shaped hopper 1 fixedly mounted on the lower end of the bracket. The bottom center of the hopper is formed with a discharge pipe 11; the bracket is located below the hopper and connected with a Bottom plate 12.

[0071] The throwing assembly includes a floating support 5 above the water surface, a plurality of buoys connected to the floating support through connecting rods, a lower bottom plate 52 fixedly connected to the lower end of the floating support, and rotatably connected to the upper end of the floating support for The feed is thrown into the throwing tray in the fish pond; eac...

Embodiment 2

[0111] combine Figure 17 to Figure 19 As shown, this embodiment makes the following improvements on the basis of Embodiment 1: it also includes a material transport assembly 7 located on one side of the storage assembly; the material transport assembly includes a conveyor belt seat 71, and is installed on the conveyor belt The conveyor belt 72 on the seat; the outer wall of the conveyor belt is evenly fixed with spikes 720, so that after a bag of feed is placed on the conveyor belt, the spikes enter the bag, so that the feed will not slip during transportation. The outer wall of the conveyor belt has no spikes near the two sides.

[0112] The conveyor belt is sequentially composed of a placing part 721 arranged horizontally close to the bottom surface, a feeding part 722 arranged obliquely and extending to the top of the chute, and a feeding part 723 arranged obliquely into the chute.

[0113] The two ends of the inner wall of the conveyor belt on the conveyor belt seat are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com