Feed feeding vehicle for livestock breeding

A feed and feeding port technology, applied in the field of aquaculture, can solve the problems of low feeding amount, low efficiency, easy agglomeration of feed, etc., and achieve the effects of convenient operation, prevention of feed clogging and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

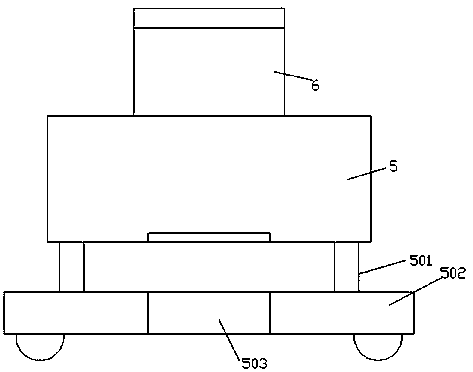

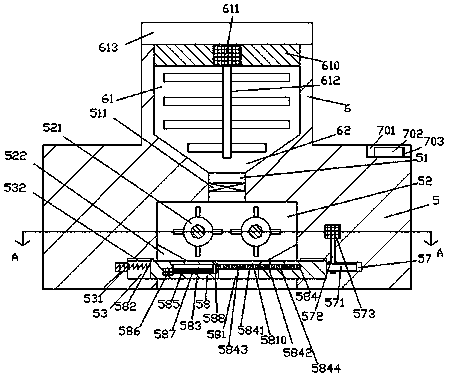

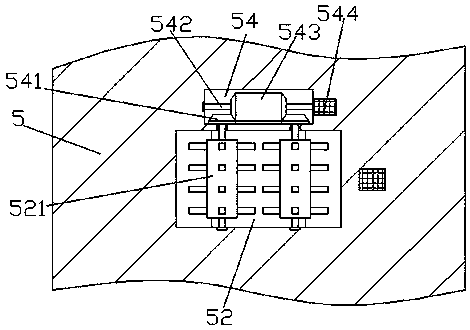

[0025] Such as Figure 1-Figure 5 As shown, a feed-feeding vehicle for animal husbandry of the present invention includes a feed-feeding body 5 and a mixing box 6 installed on the top of the feed-feeding body 5, and a mixing chamber 61 is provided in the mixing box 6. The bottom of the mixing chamber 61 is provided with a downwardly extending cone-shaped cavity 62, the bottom extension of the cone-shaped cavity 62 extends into the feed feeding machine body 5, and the bottom and tail of the cone-shaped cavity 62 is penetrated with Discharge outlet 51, the bottom surface of the feed feeding body 5 is provided with a discharge groove 52 with a top and a bottom end of the discharge port 51 penetratingly arranged. The inner walls of the left and right sides of the discharge groove 52 are correspondingly provided with sliding grooves 53. The inner top wall of each of the sliding grooves 53 is provided with a guide groove 532, and between the sliding grooves 53 on the left and right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com