Methods for manufacturing a spring, a spring brake, and a spring brake comprising a spring

A manufacturing method and brake technology, applied in the manufacture of springs and spring brakes and the field of spring brakes with springs, can solve problems such as noise, and achieve the effect of reducing the risk of unqualified springs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

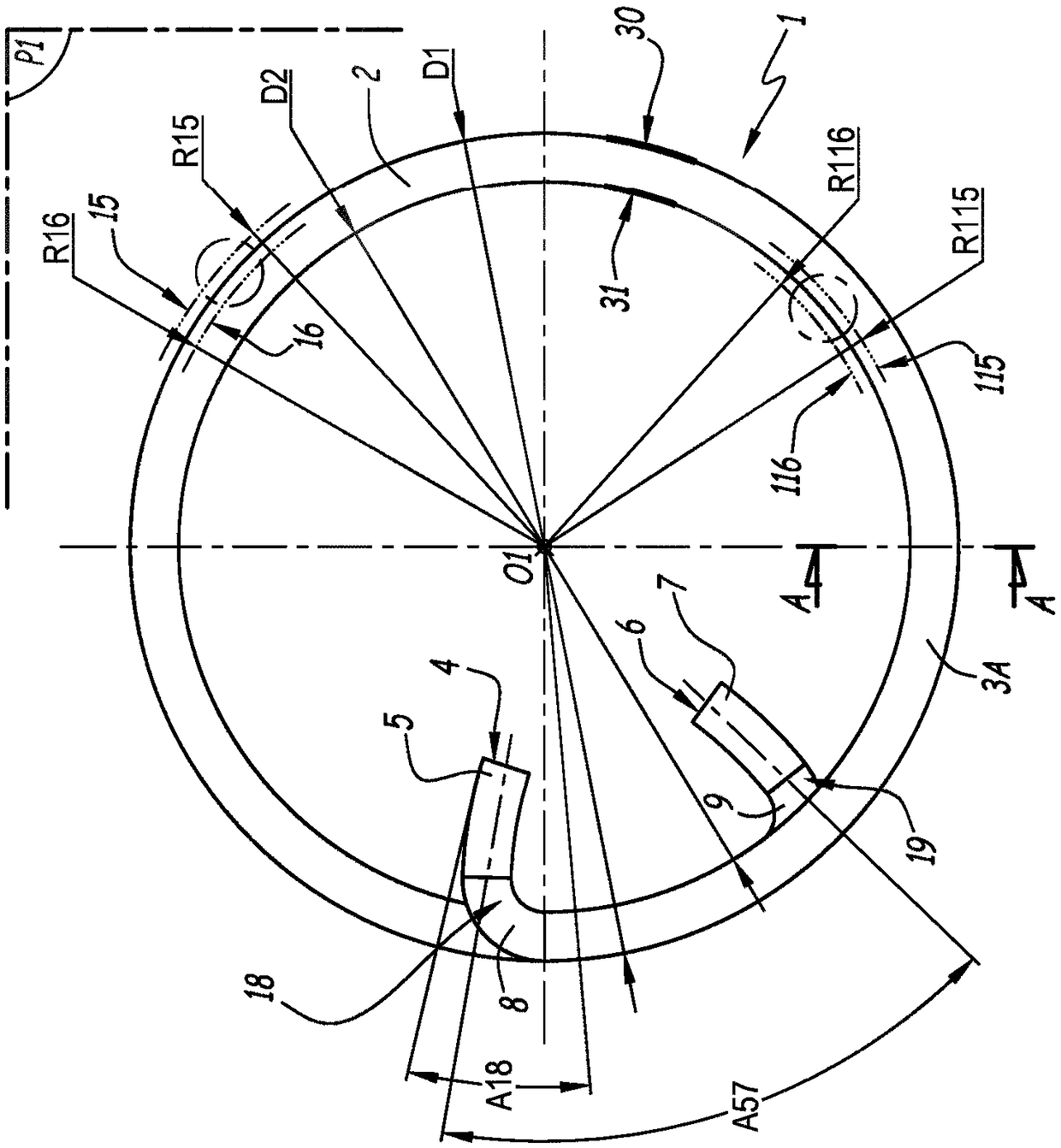

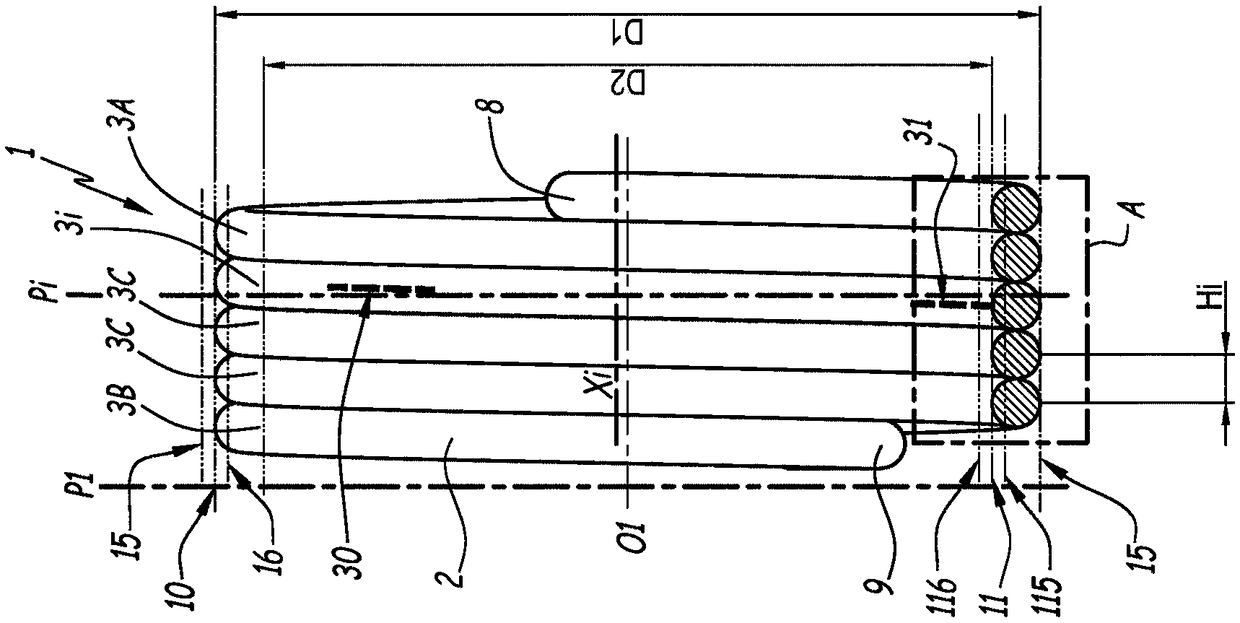

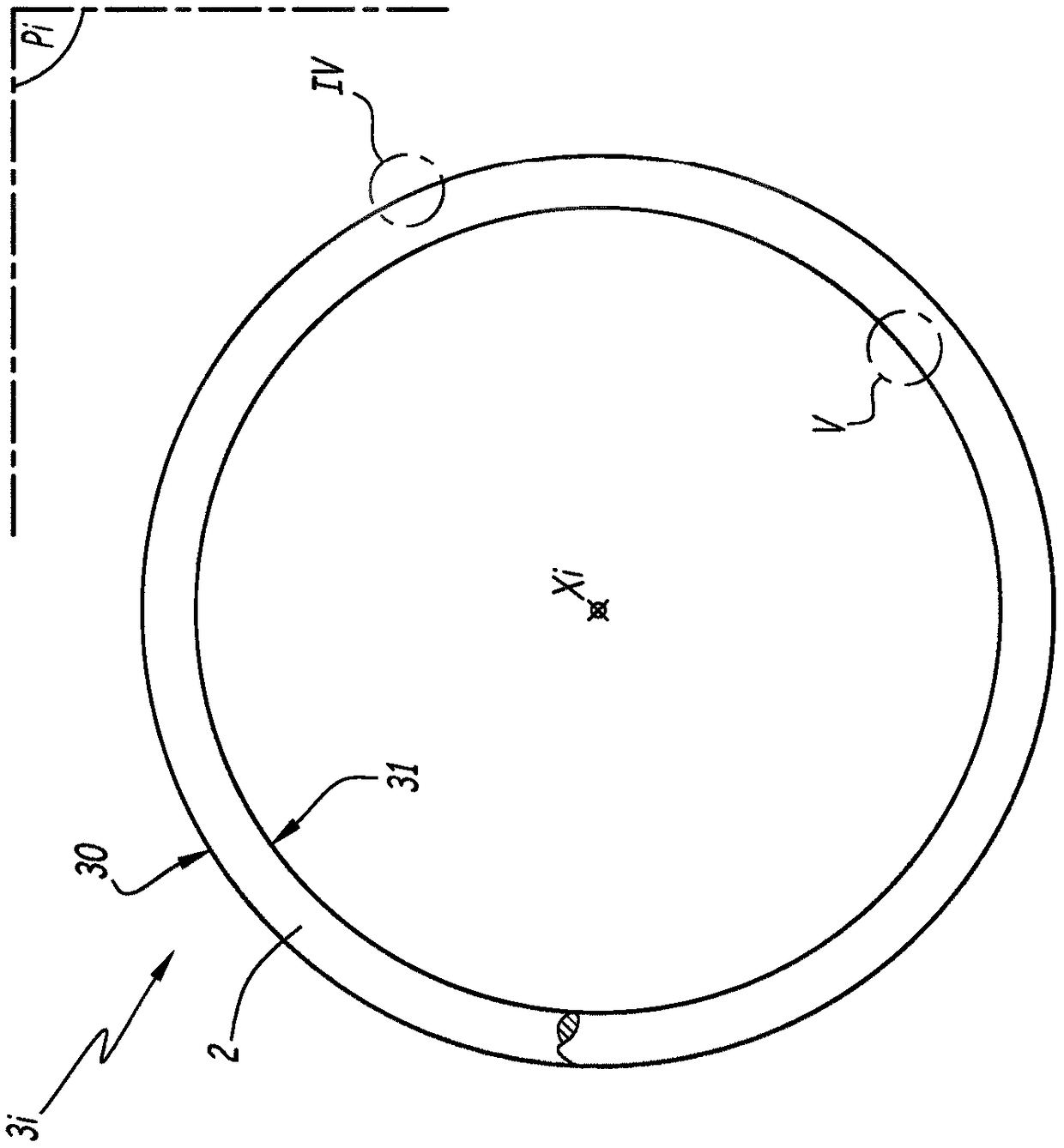

[0023] figure 1 with 2 The spring 1 shown in FIG. 1 includes a spring wire 2 formed in a spiral profile, that is, spirally wound. Therefore, the reed wire 2 is wound with a plurality of coils 3i contained in a spiral profile. The spiral profile is arranged to be coaxial with the common main axis O1 of the spring 1, so that each coil 3i is approximately centered on the main axis O1. Each coil 3i defines a coil axis Xi coaxial with the associated coil 3i, such as figure 2 with 3 Shown. When manufacturing the spring 1, it is desirable that the coil axis Xi of each coil is ideally coaxial with the main axis O1, but this is not necessarily the case in practice, because there may be defects in the spring 1. The helical profile of the spring 1 is used to extend in a right cylinder with a circular base coaxial with the main axis O1.

[0024] The so-called "spring coil" refers to a part of the one wire 2, which is contained in the spiral profile of the spring 1, and extends coaxially w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com