Device and method for fast alignment of datum in NC machining of non-regular shape structure wool

A processing benchmark and fast technology, applied in the direction of automatic control devices, positioning devices, feeding devices, etc., can solve the problems of inability to realize the rapid alignment of the datum by numerical control, the inability to accurately align the machining datum, and uneven machining allowance of castings, etc. Achieve the effects of reducing the risk of product failure, great practical value, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

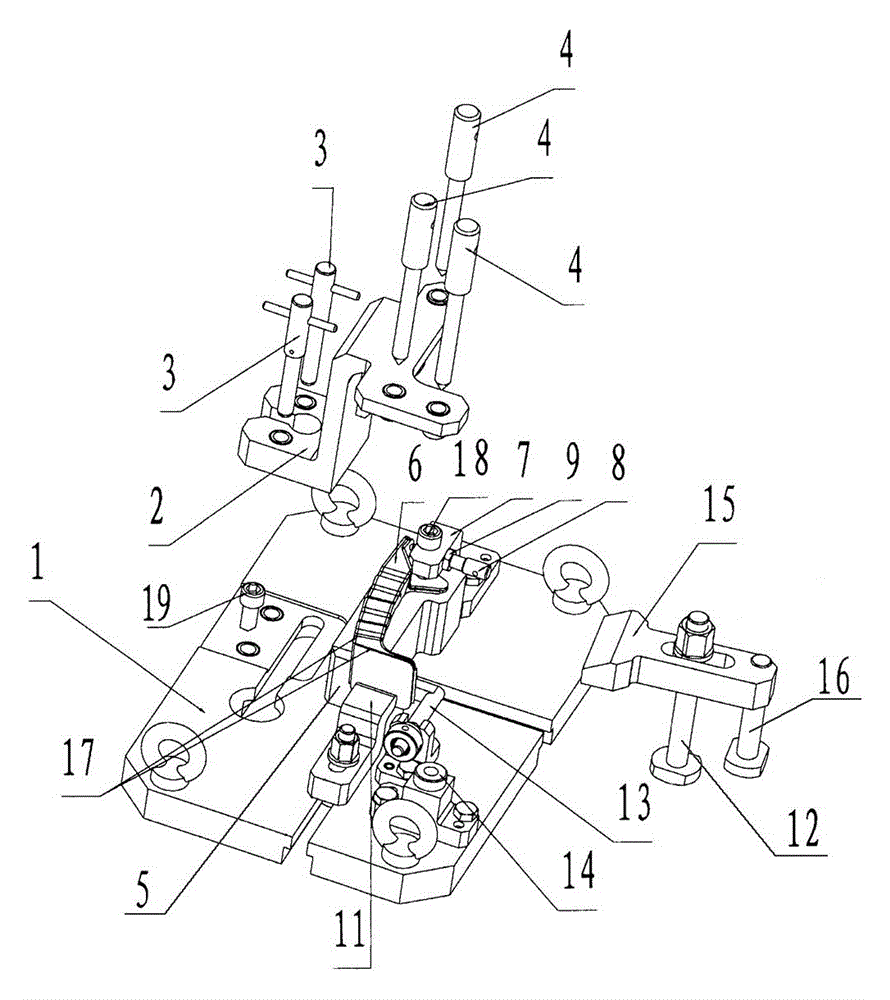

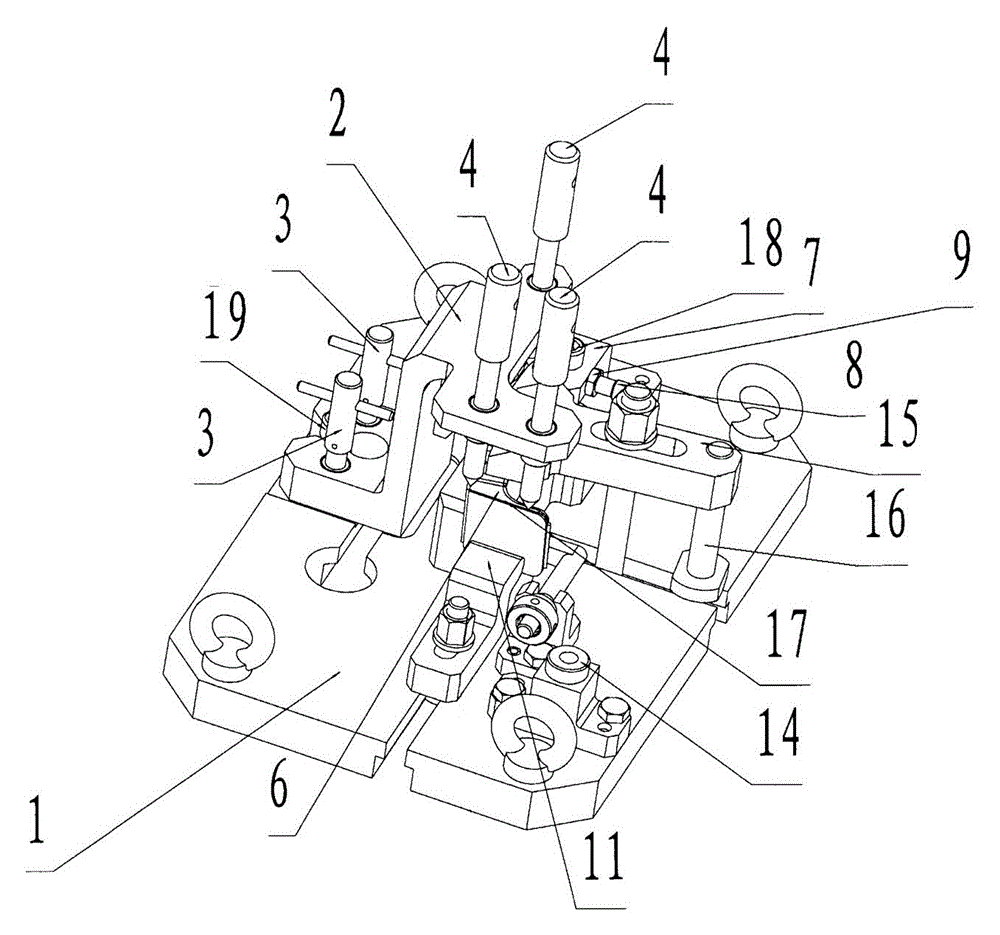

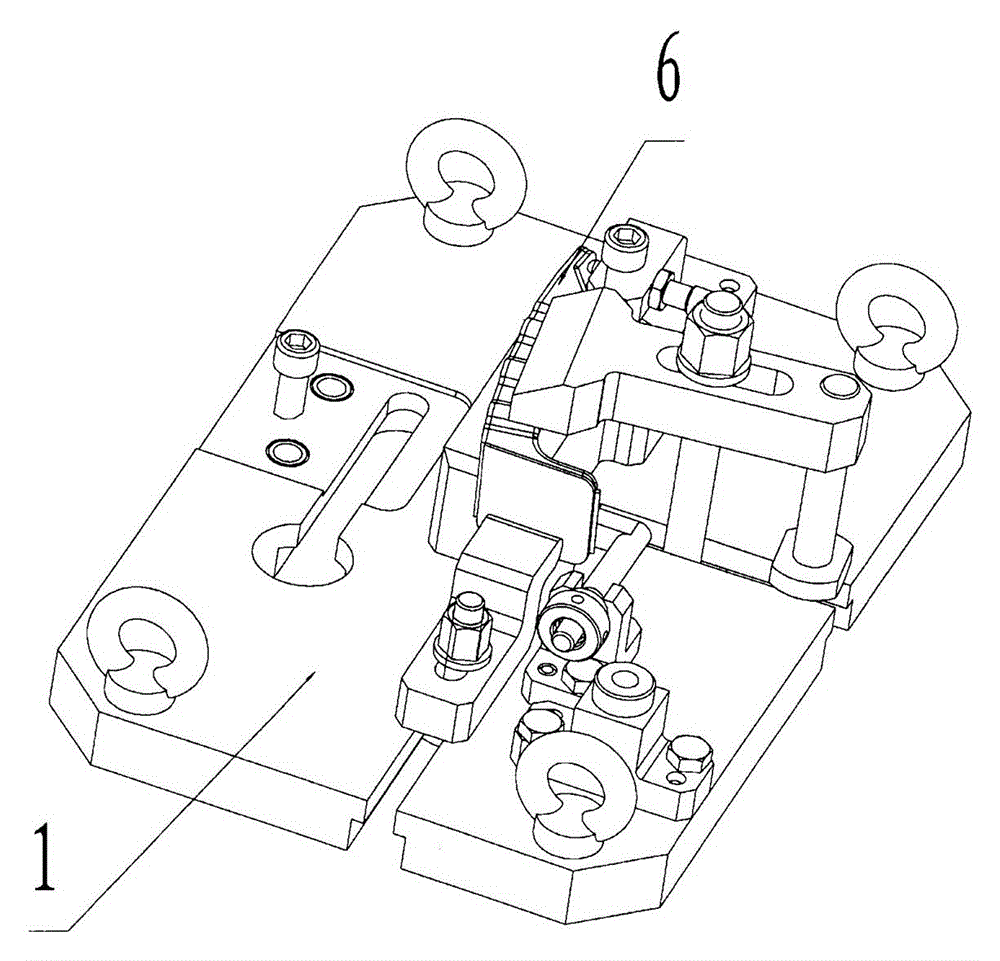

[0021] like Figure 1 to Figure 3 As shown in the figure, a quick alignment device for numerical control machining of wool with an irregular shape structure is provided with a support table 5 on the milling fixture 1, and a positioning device 10 is arranged on the length direction of the support table 5. One end is provided with a quick alignment device 20, the other end is provided with a pressure plate 15, and the end of the pressure plate 15 is located above the support table 5; wherein the positioning device 10 and the pressure plate 15 are respectively connected with the milling fixture 1 movably; in the quick alignment device 20 It is composed of a Z-shaped quick alignment device 2, two cylindrical positioning pins 3 and a number of conical alignment pins 4, wherein the outer contour of the upper surface of the quick alignment device 2 is larger than the projected view contour of the casting to be processed. There are several conical alignment pins 4 on the upper bending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com