Heating control device and control method for multi-strand insulated self-made thermal overhead ground wire

A technology for controlling equipment and strand insulation, which is applied in overhead installation, cable installation, electrical components, etc., can solve the problem of no precise control method of current, no method of anti-icing and melting of overhead ground wires of transmission lines, pressure poor control and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

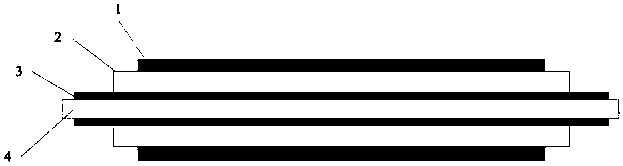

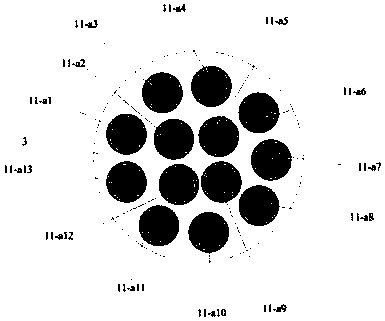

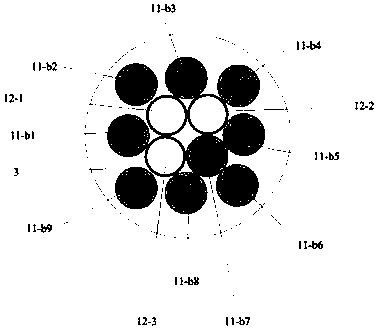

[0088] See attached figure 1 , 2 .

[0089] The multi-strand insulated self-made thermal overhead ground wire is a wire, which is composed of an outer conductor 1, a protective metal ring 2, an insulating heat conducting ring 3 and an inner heating ring 4 from the outside to the inside; the two ends of the wire are called the A end and the B end; The thermal control equipment is connected to the terminal of the multi-strand insulated self-made thermal overhead ground wire.

[0090] When the inner heating ring 4 of the multi-strand insulated self-made thermal overhead ground wire is an insulating structure or an insulated optical fiber structure, the multi-strand insulated self-made thermal overhead ground wire is sequentially composed of the outer conductor 1, the protective metal ring 2 and the inner heating ring from the outside to the inside. 4, or sequentially composed of an outer conductor 1, a protective metal ring 2, an insulating heat conducting ring 3 and an inner h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com