Trench gate MOSFET and manufacturing method thereof

A manufacturing method and trench gate technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of reduced device performance, poor current path uniformity, etc., to achieve uniform current path, improve breakdown voltage, improve The effect of pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

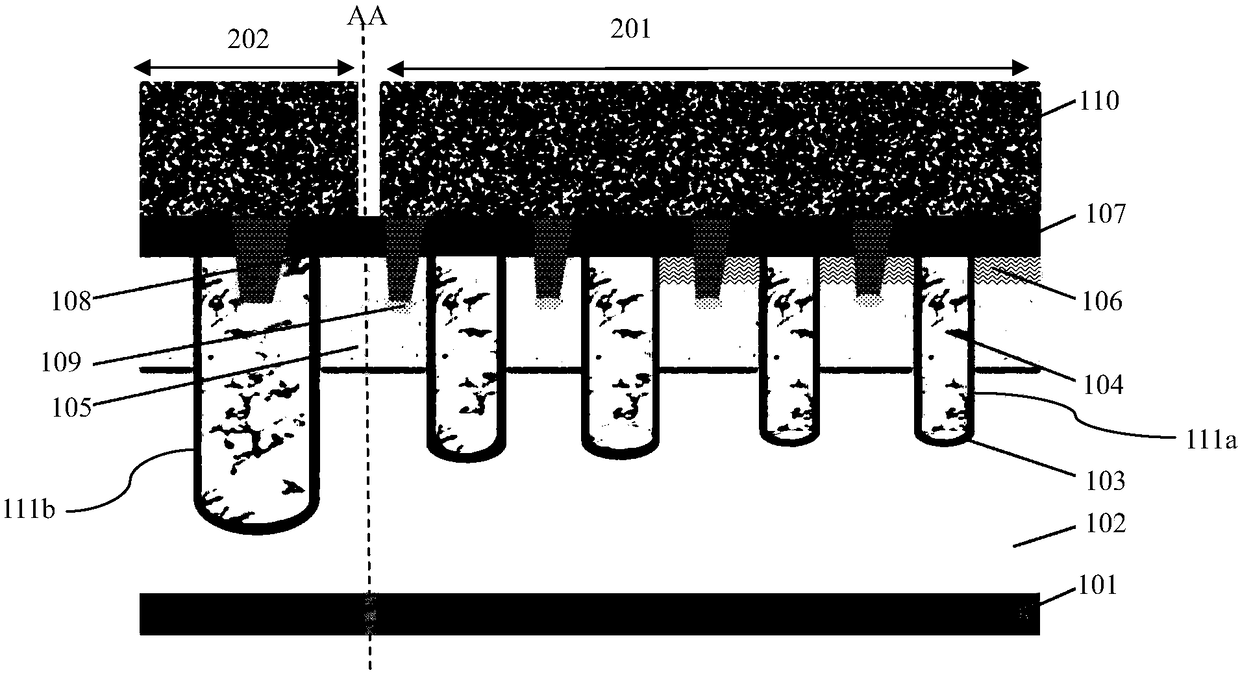

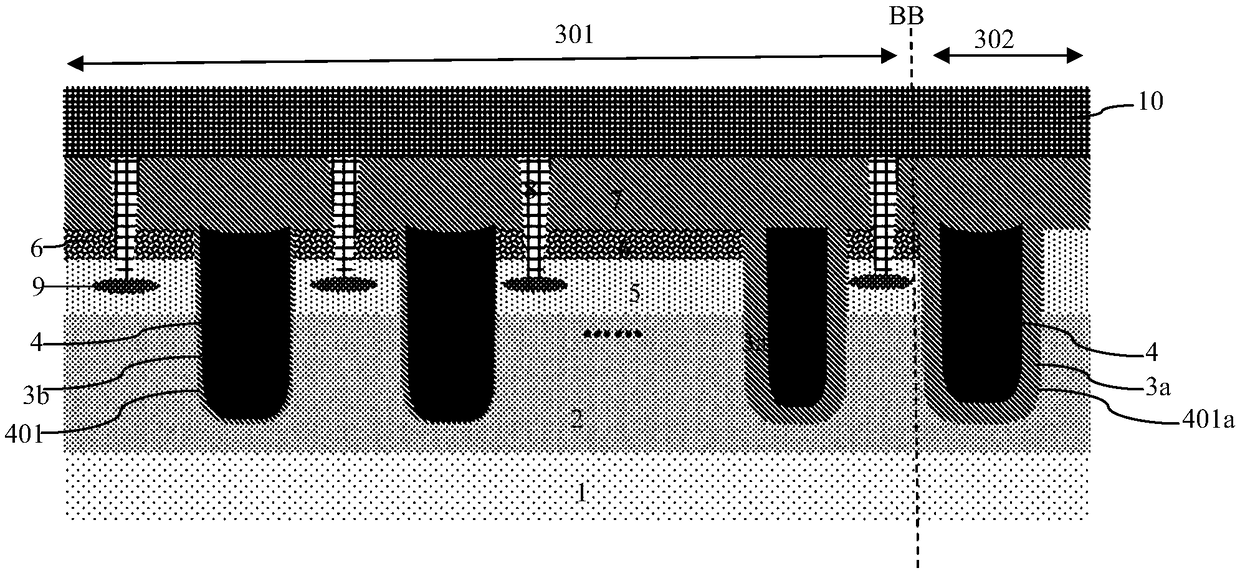

[0058] like figure 2 As shown, it is a schematic structural diagram of a trench gate MOSFET according to an embodiment of the present invention. The trench gate MOSFET according to this embodiment of the present invention includes an inner region and an edge region, figure 2 In the sectional view of , the inner area and the edge area are separated by a dotted line BB, the inner area is indicated by a mark 301 , and the edge area is indicated by a mark 302 . The inner region is the conduction region of the trench gate MOSFET, which is composed of a plurality of primitive cells arranged periodically; the edge region is located at the edge of the conduction region, and is used to connect the primitive cells in the conduction region The gate structure leads out.

[0059] Both the drift region 2 of the first conductivity type and the body region 5 of the second conductivity type are formed in the inner region and the edge region, and the body region 5 is located on the surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com