Micron capillary gas-liquid dynamic phase interface testing device

A testing device and capillary technology, which is applied in the direction of soil material testing, material inspection products, etc., can solve the problems that the contact angle cannot be directly measured, the movement process of the phase interface cannot be observed, and the phase interface cannot be observed, so as to improve efficiency and measure The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

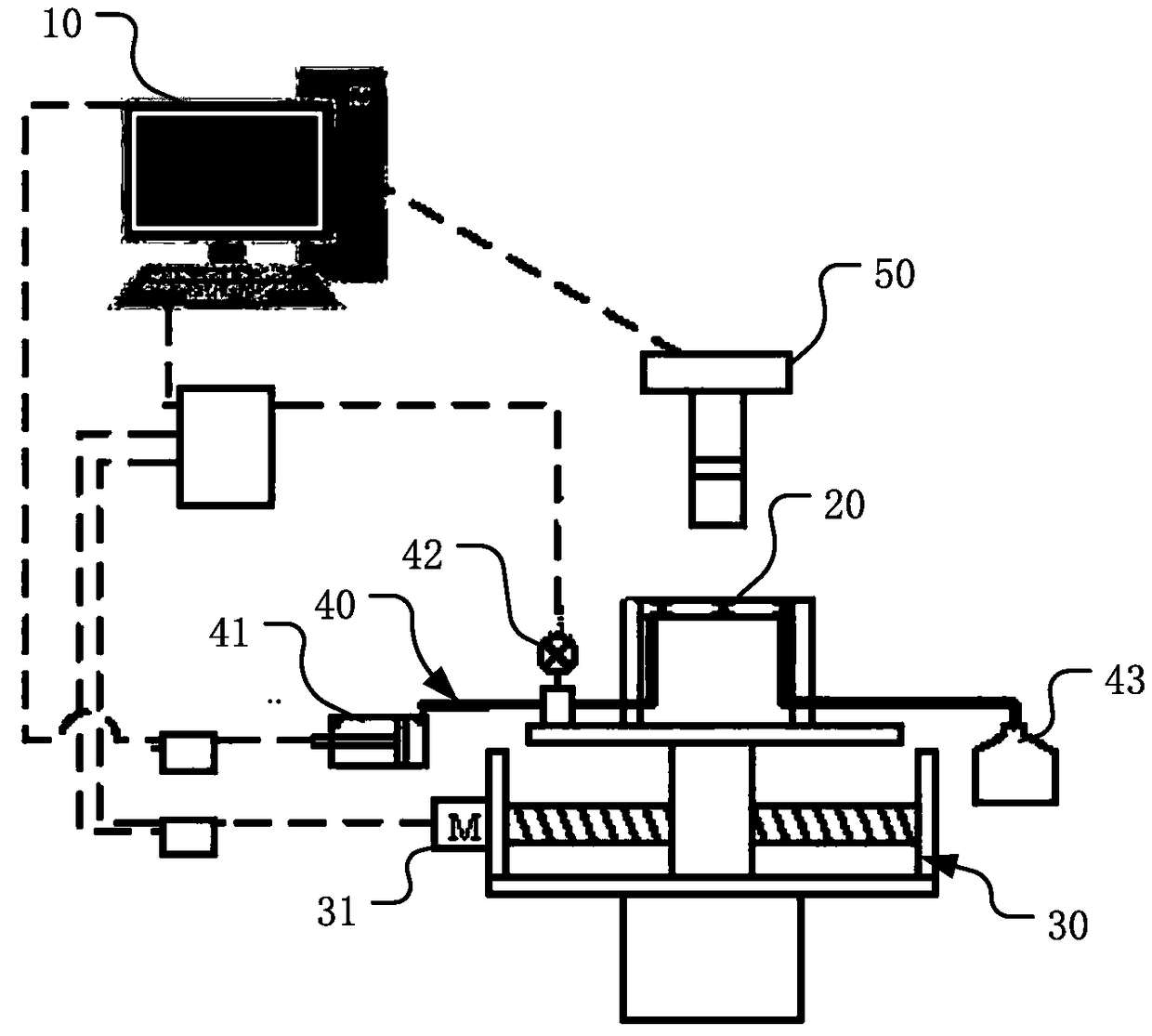

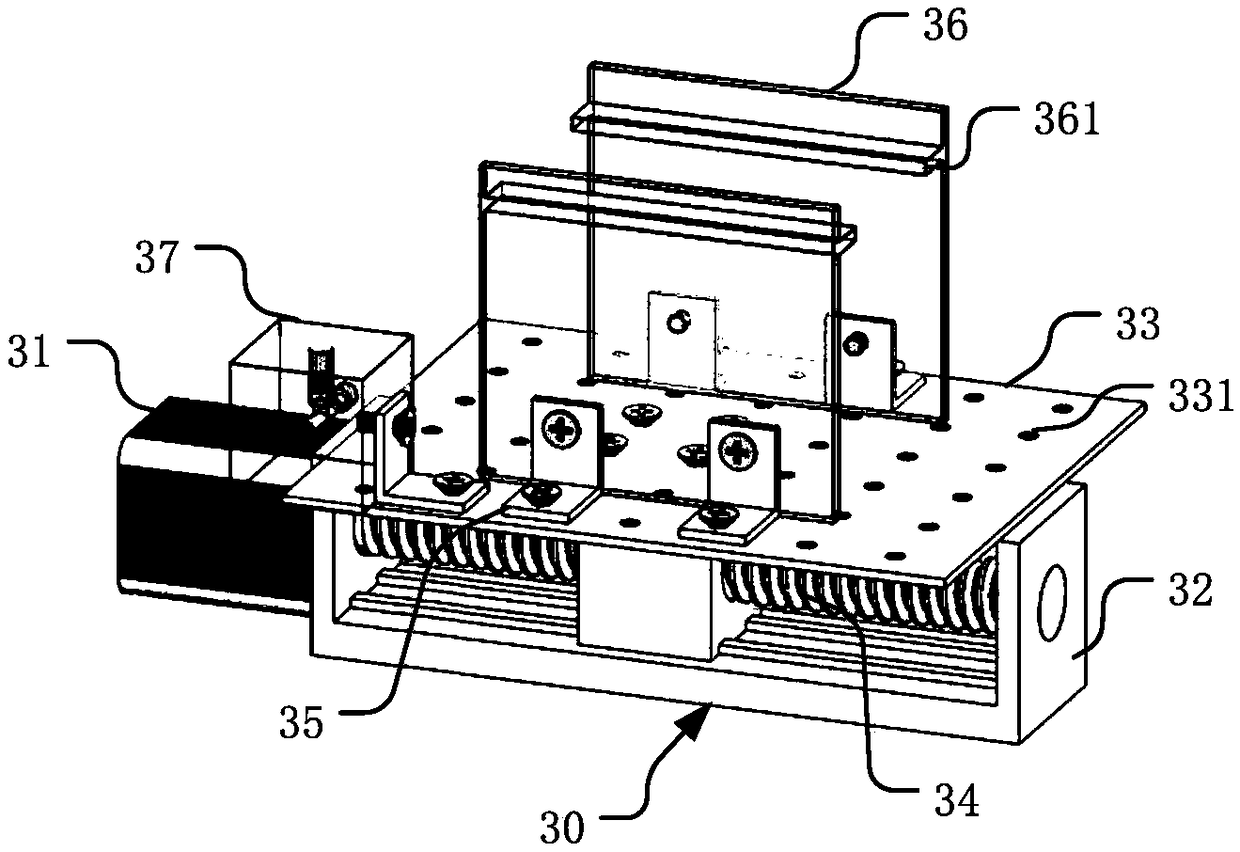

[0041] Such as figure 1 , 2 , 3, the present invention provides a micron capillary gas-liquid dynamic contact angle electric test platform, which generally includes a microfluidic chip 20, a pressure control pipeline 40, a mobile platform 30, a camera unit 50 and a control system 10.

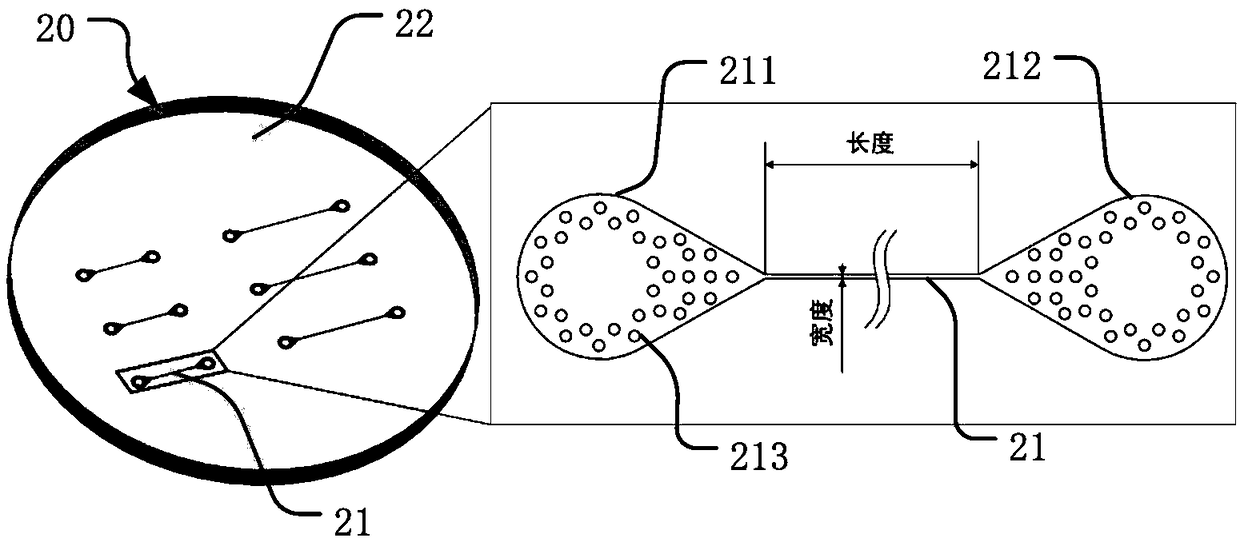

[0042] The microfluidic chip 20 is used for passing the test liquid, and is provided with a micron capillary channel 21; the specific microfluidic chip 20 can be a plate-shaped structure made of glass, organic material, or the like. The micron capillary channel 21 is the place where gas-liquid dynamic two-phase displacement occurs, and it needs to have sufficient strength, processing accuracy and operability. According to the requirements of this embodiment, the characteristic size of the microcapillary channel 21 is in the range of 10-100 μm, such as 20, 40 and 80 μm used in this embodiment, and tested respectively.

[0043]Concrete microfluidic chip 20 can adopt polydimethylsiloxane (PDMS) m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com