Electric control chamber arrangement structure under copper alloy casting furnace platform

A technology for laying out structures and melting and casting furnaces, applied in furnace control devices, furnaces, furnace components, etc., can solve problems such as large line loss and long-term operating loss, achieve low line and operating loss, reduce production and operation costs, and ensure safety and reliability. running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

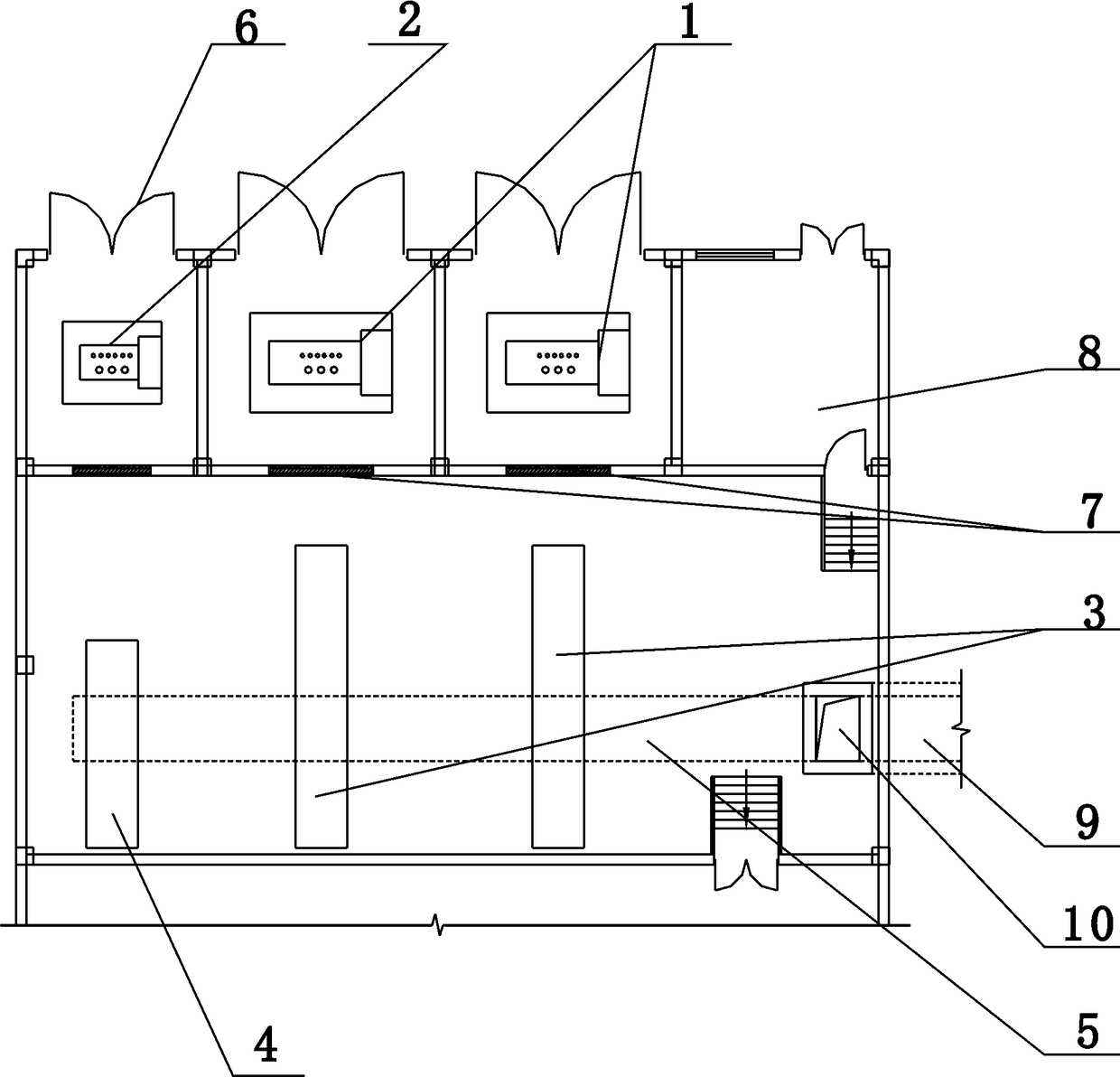

[0019] combined with figure 1 The layout structure of the electric control room under the copper alloy melting and casting furnace platform includes the transformer room and the power control room arranged adjacently in front of and behind the lower part of the equipment furnace platform. There are multiple air intake fire-proof shutters 7, and the transformer room is set behind the lower part of the equipment stove. The doors of the transformer room are all Class A fire doors 6, and they are opened towards the workshop. In the transformer room, there are melting furnace transformers and insulation Furnace transformer, the upper part of the class A fire door 6 in the transformer room is equipped with air outlet fire shutters, and the multiple air inlet fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com