Multi-channel oil returning floater gas-liquid separator

A gas-liquid separator and oil float type technology, which is applied in the field of multi-channel oil return float type gas-liquid separators for air source heat pump air conditioning units, can solve the problem of rising oil level, compressor oil shortage, and refrigerant droplets. Into the compressor and other problems, to reduce the risk of liquid hammer, ensure the oil return effect, reduce the effect of harmful overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

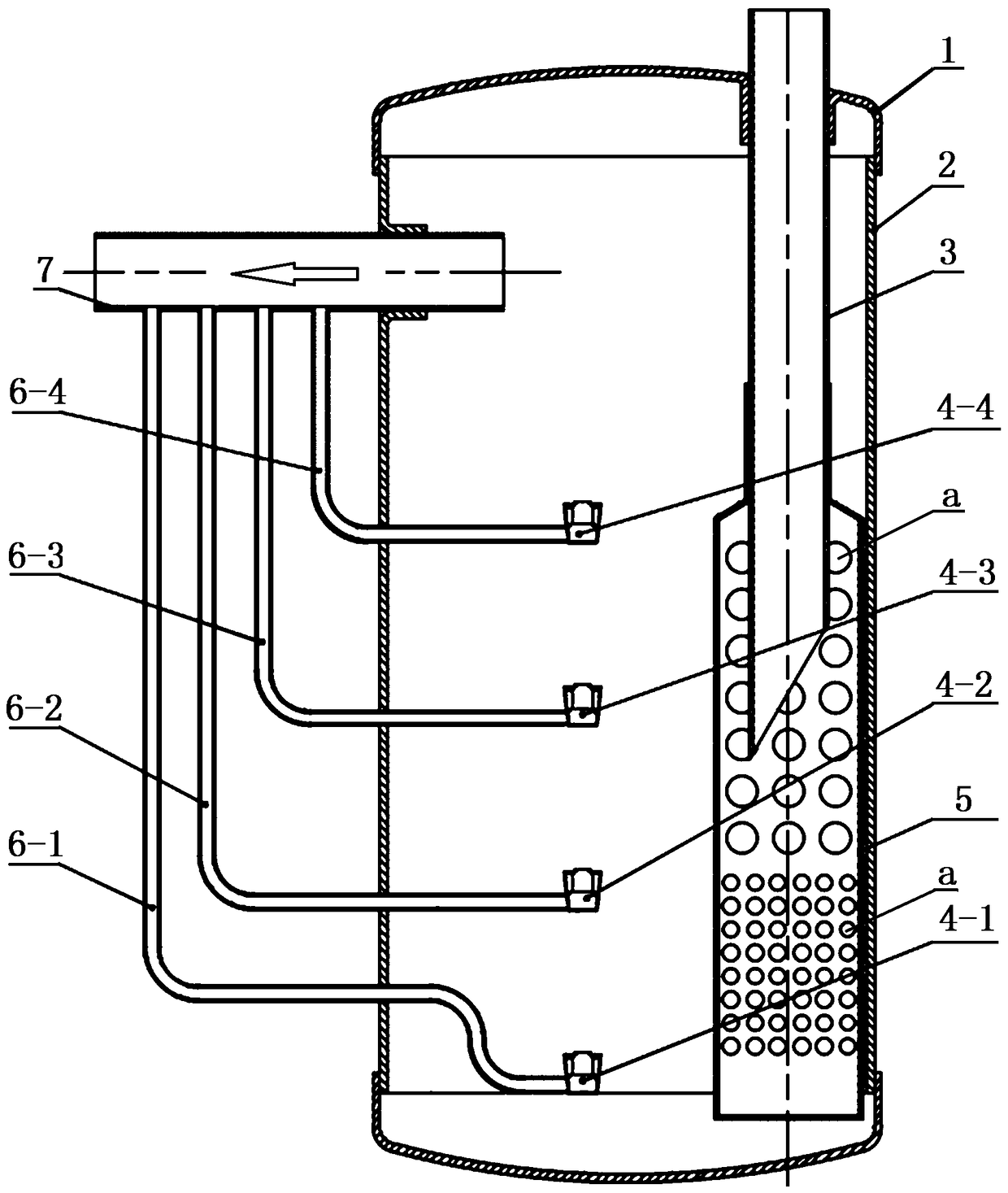

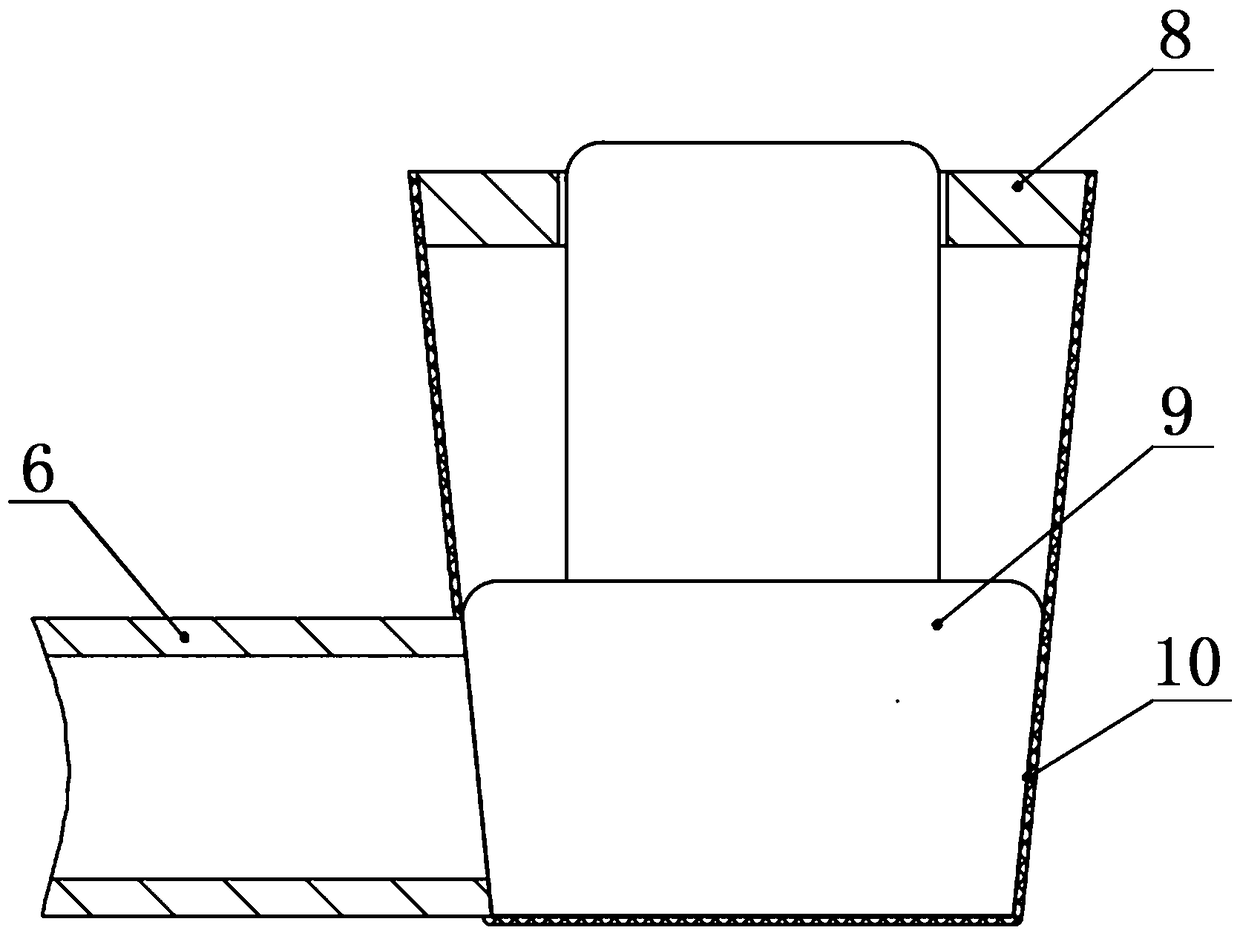

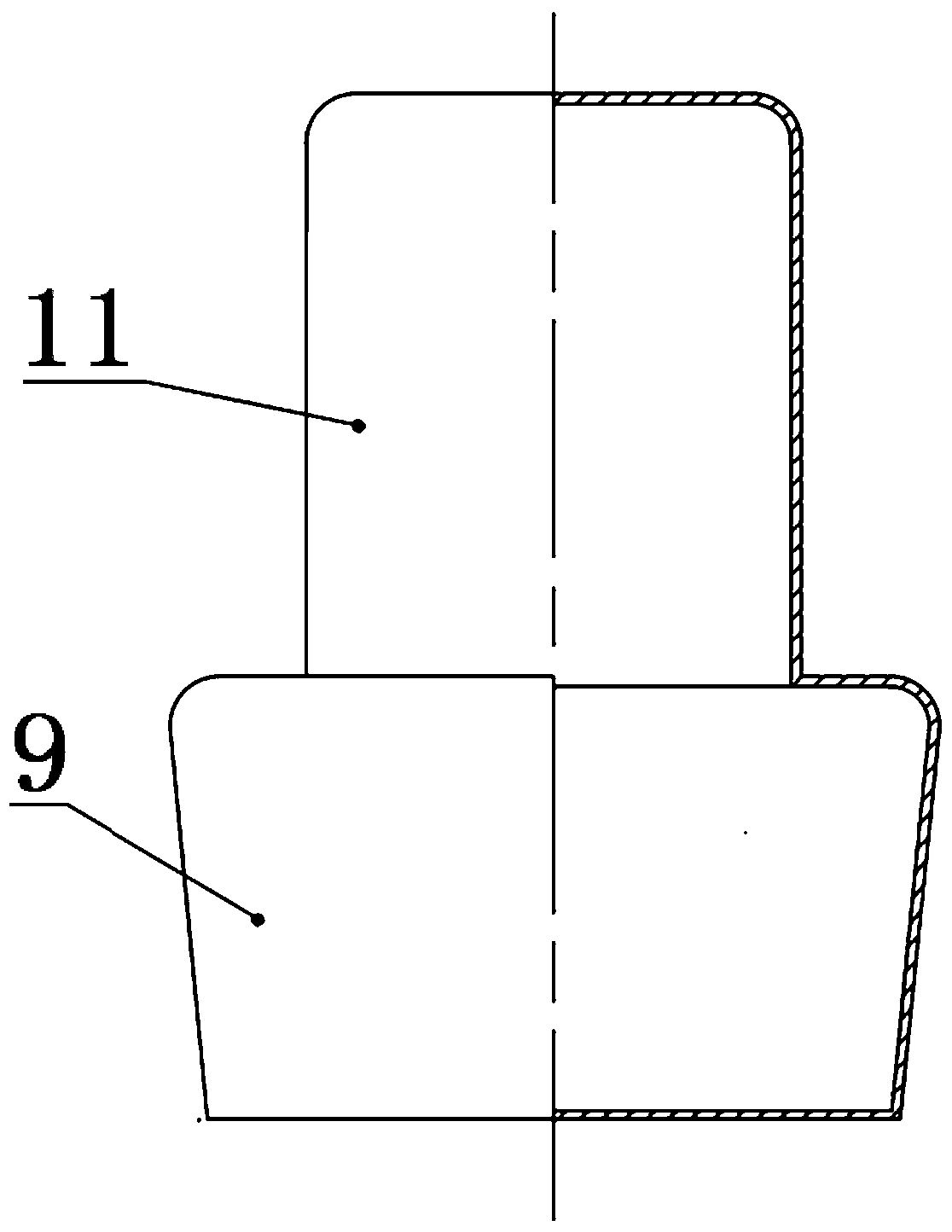

[0035] When the air conditioner unit is running stably, the refrigerant gas in the evaporator enters the gas-liquid separator cylinder 5 connected to the gas-liquid separator inlet 3 through the gas-liquid separator inlet 3 . In the gas-liquid separation cylinder 5, because the gaseous refrigerant needs to enter the interior of the gas-liquid separator through the vent hole on its side wall, the effect of gas-liquid separation is strengthened; at the same time, if the gaseous refrigerant contains impurities, it can also be deposited in the gas-liquid separation cylinder. 5 at the bottom, so that the gas-liquid separation cylinder 5 also has the function of coarse filtration. At this time, the amount of liquid refrigerant in the gas-liquid separator is not large, and the liquid level of the liquid refrigerant should be near the low-level oil return module 4-1. The oil return float 9 floats vertically upward under the action of the guide post 11 and the oil return float screen b...

Embodiment 2

[0037] When the system defrosts or the load changes greatly, the refrigerant gas in the evaporator enters the gas-liquid separation cylinder 5 connected to the gas-liquid separator inlet 3 through the gas-liquid separator inlet 3 . In the gas-liquid separation cylinder 5, the gaseous refrigerant needs to enter into the gas-liquid separator through the air holes on its side wall, which strengthens the effect of gas-liquid separation. At the same time, if the gaseous refrigerant contains impurities, it can also be deposited at the bottom of the gas-liquid separation cylinder 5, so that the gas-liquid separation cylinder 5 also has the function of coarse filtration. At this time, the amount of liquid refrigerant in the gas-liquid separator will increase greatly, and the liquid level of liquid refrigerant will gradually rise, and it will reach the second-lowest oil return module 4-2 and the second-highest oil return module 4 in sequence according to different operating conditions. ...

Embodiment 3

[0039] Under the working condition of system defrosting, while the low-level oil return module 4-2, the next highest oil return module 4-3 and the high-level oil return module 4-4 where the refrigerant liquid level is located return oil, At this time, the oil return module plays the role of cooling the return air, and through the throttling and pressure reduction of the corresponding sub-lower oil return capillary 6-2, second-higher oil return capillary 6-3 and high-level oil return capillary 6-4, the return air The liquid is depressurized and vaporized, absorbing the heat of the superheated gaseous refrigerant to reduce the suction temperature of the compressor and protect the compressor.

[0040] This patent application has the following characteristics: 1. According to the change of the air-conditioning load, multiple oil return pipes with different heights and positions can be used to return oil according to different working conditions, which solves the problem of the exis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com