Pumping mechanism and sanitary double-ring pump

A technology of dynamic ring and static ring, which is applied in the direction of pumps, pump components, mechanical equipment, etc., can solve the problems of damage to the pump body and flow-passing parts, the balance plate is not lubricated by water, and cannot be completed, so as to improve efficiency and pumping capacity , reduce loss and gas consumption, slow and soft movement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

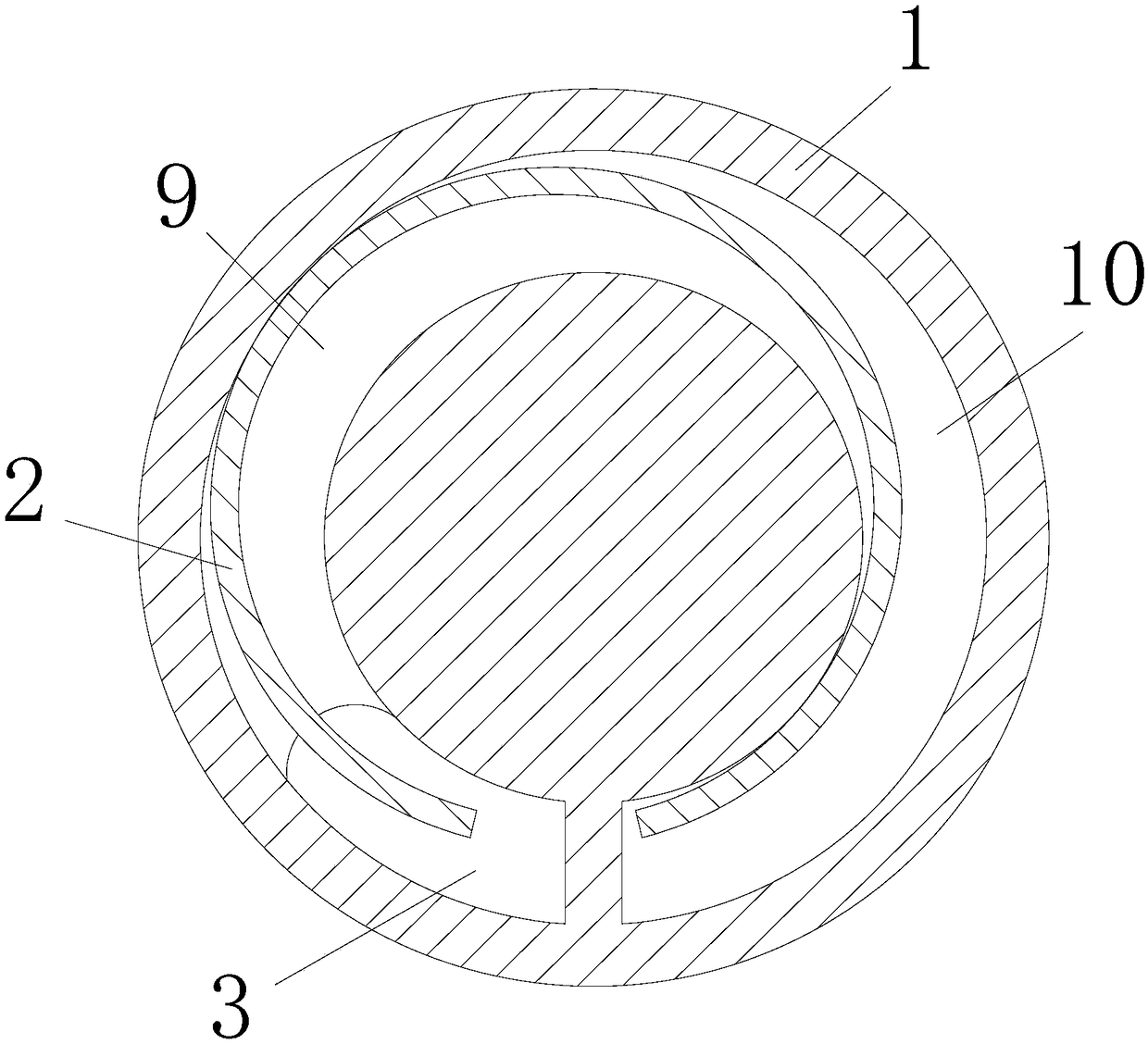

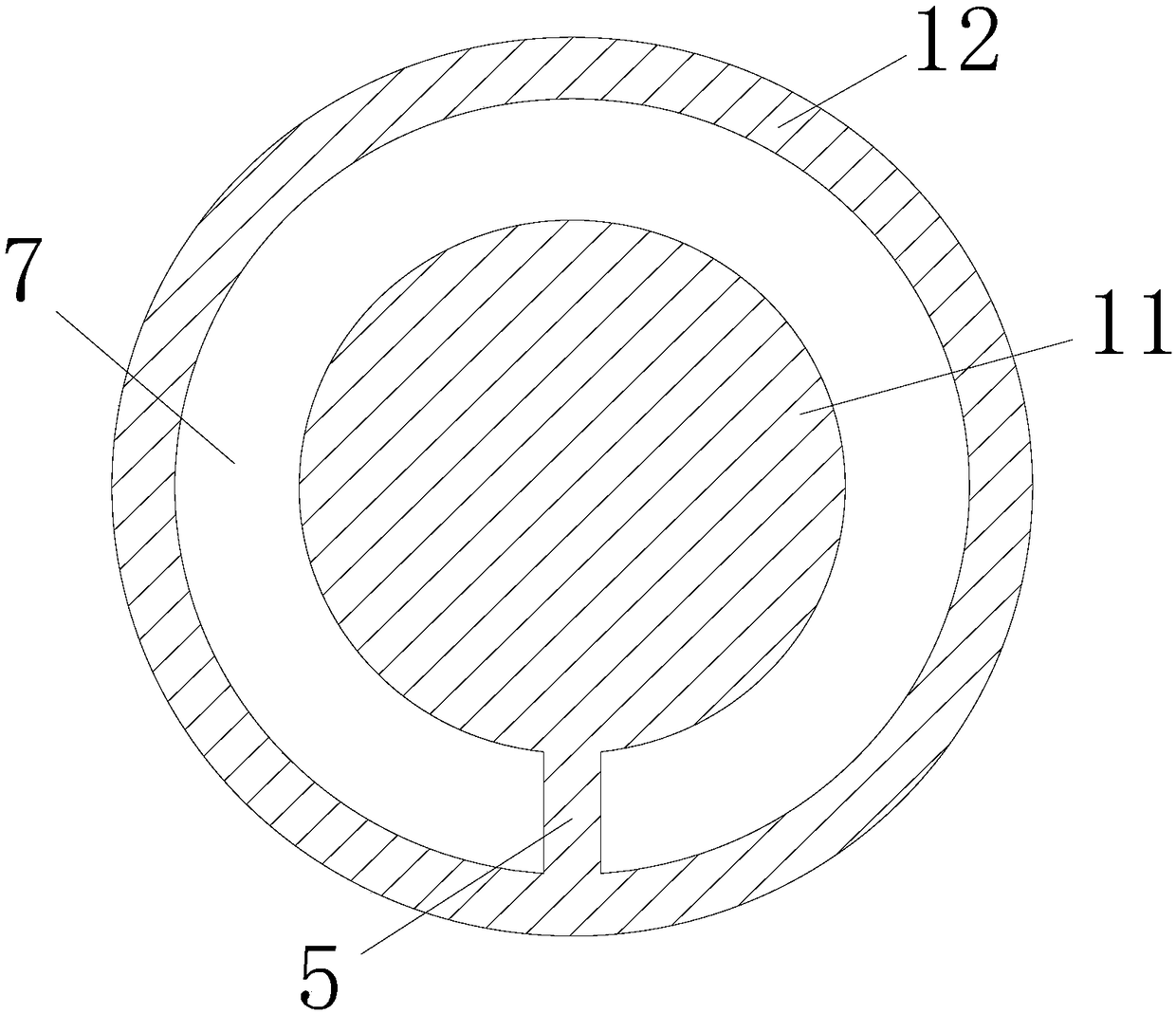

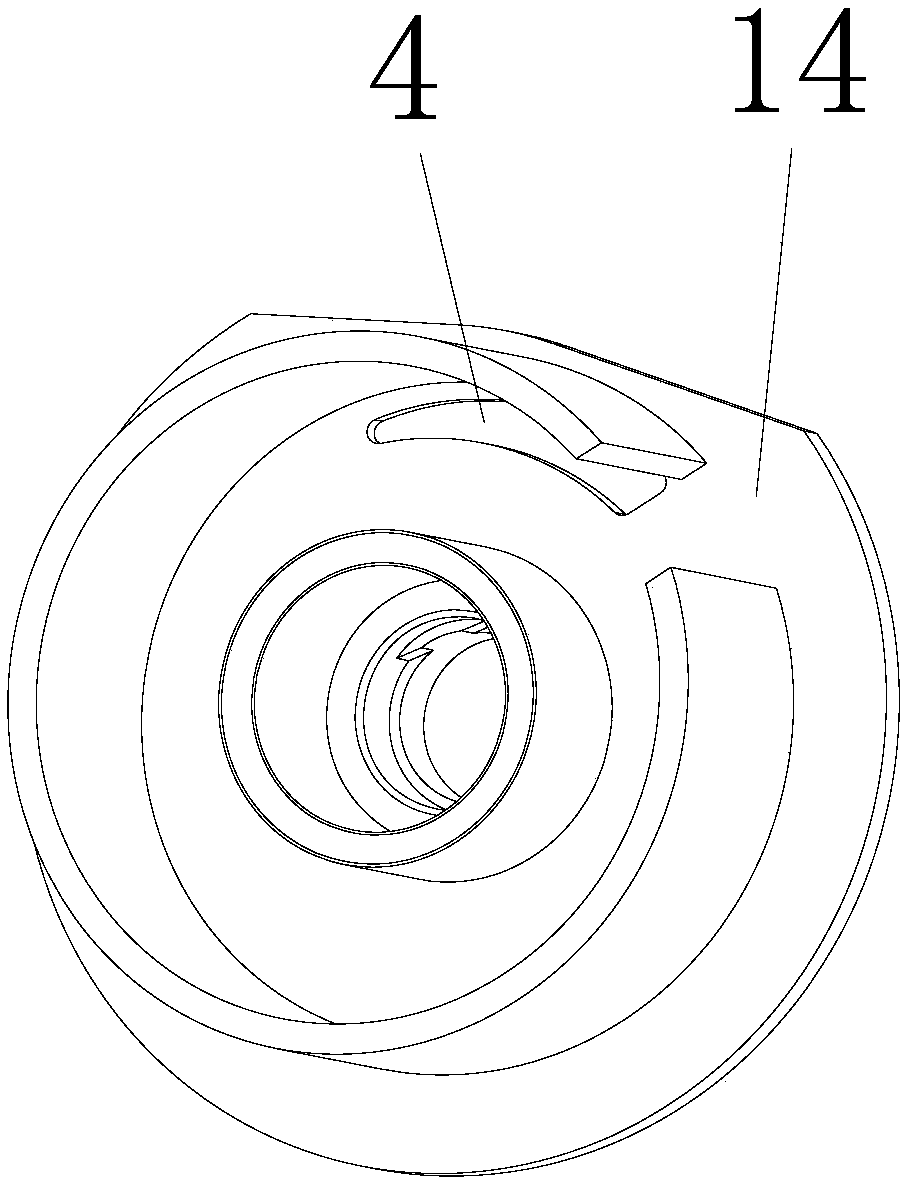

[0035] figure 1 It is a structural schematic diagram of an embodiment of the pumping mechanism of the present invention. A pumping mechanism, comprising: a static ring 1, a movable ring 2 that can swing along the circumferential direction of the wall of the static ring 1, and a partition part arranged between the discharge port 3 and the feed port 4 along the circumferential swing direction of the movable ring 2 5. When the moving ring 2 swings in the circumferential direction, the center of the static ring 1 and the moving ring 2 are staggered, and the moving ring 2 swings in the circumferential direction, forming a gap between the moving ring 2 and the static ring 1 that can convey materials along the swing direction of the moving ring 2. The transmission space 6 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com