Internal combustion locomotive anti-vibration cooling system

A heat dissipation system and technology for internal combustion locomotives, applied in mechanical equipment, engine components, engine cooling, etc., can solve problems such as poor working conditions of internal combustion engines, complex road conditions, and poor heat dissipation, so as to improve cooling capacity and reduce the number of single sections , The effect of large thermal expansion and cold contraction compensation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation of the anti-vibration cooling system for a diesel locomotive of the present invention will be described in detail below in conjunction with the accompanying drawings.

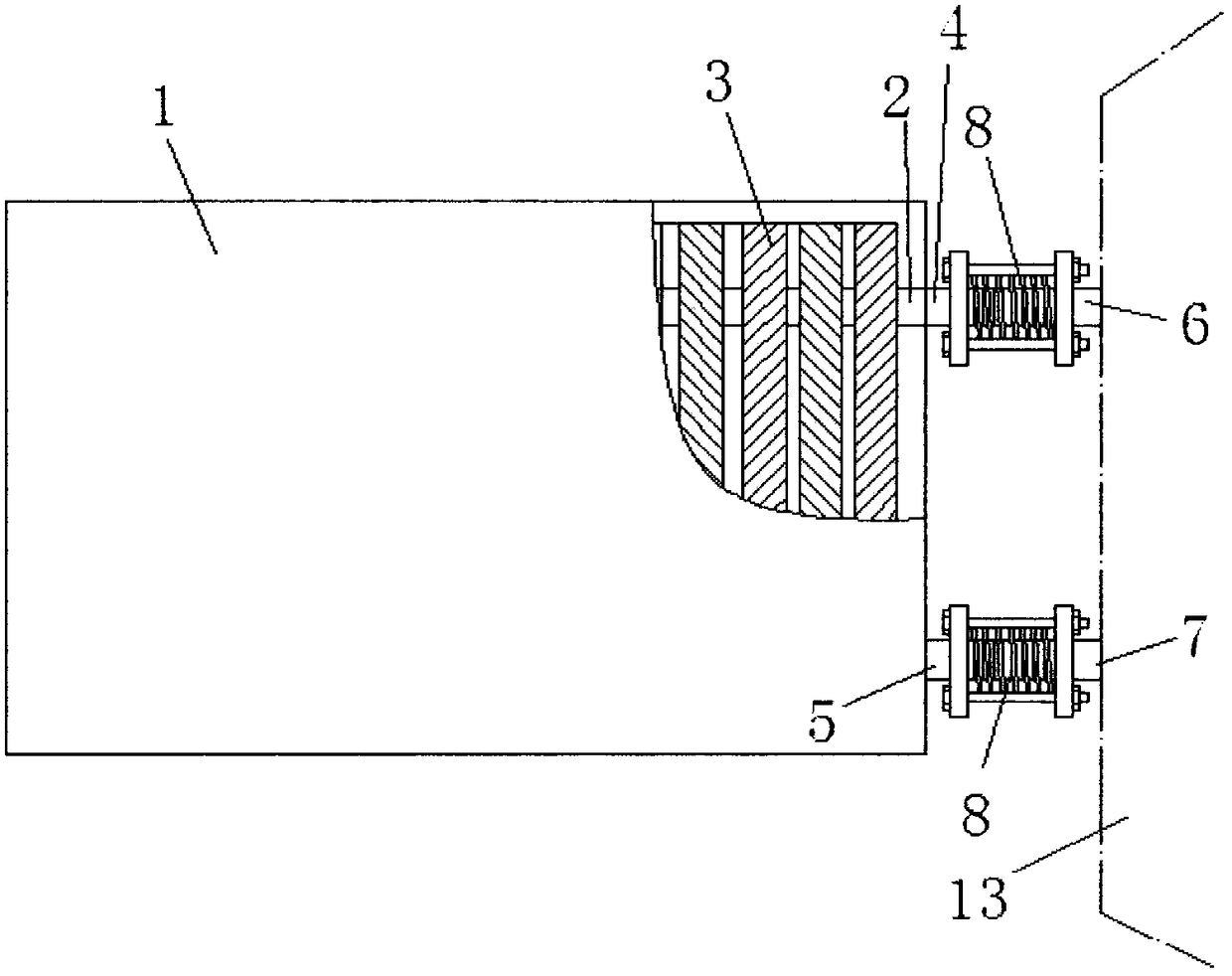

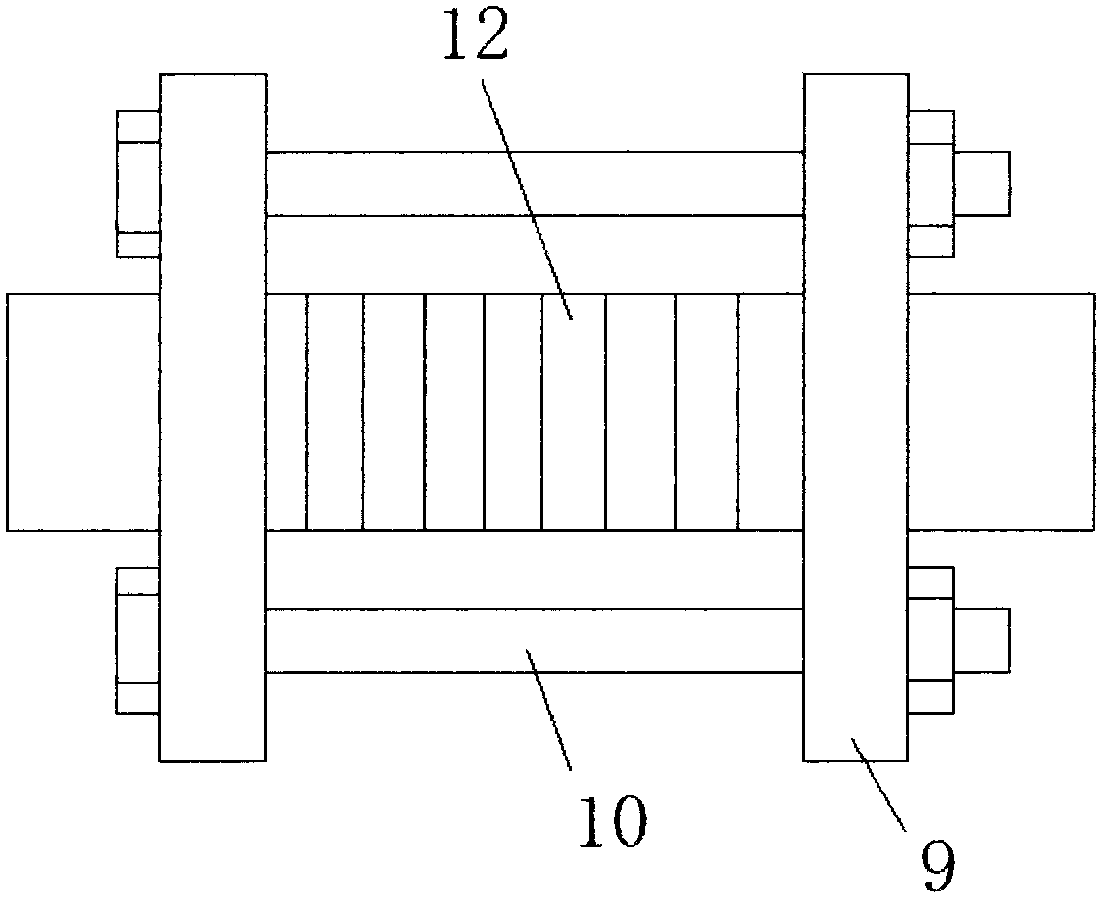

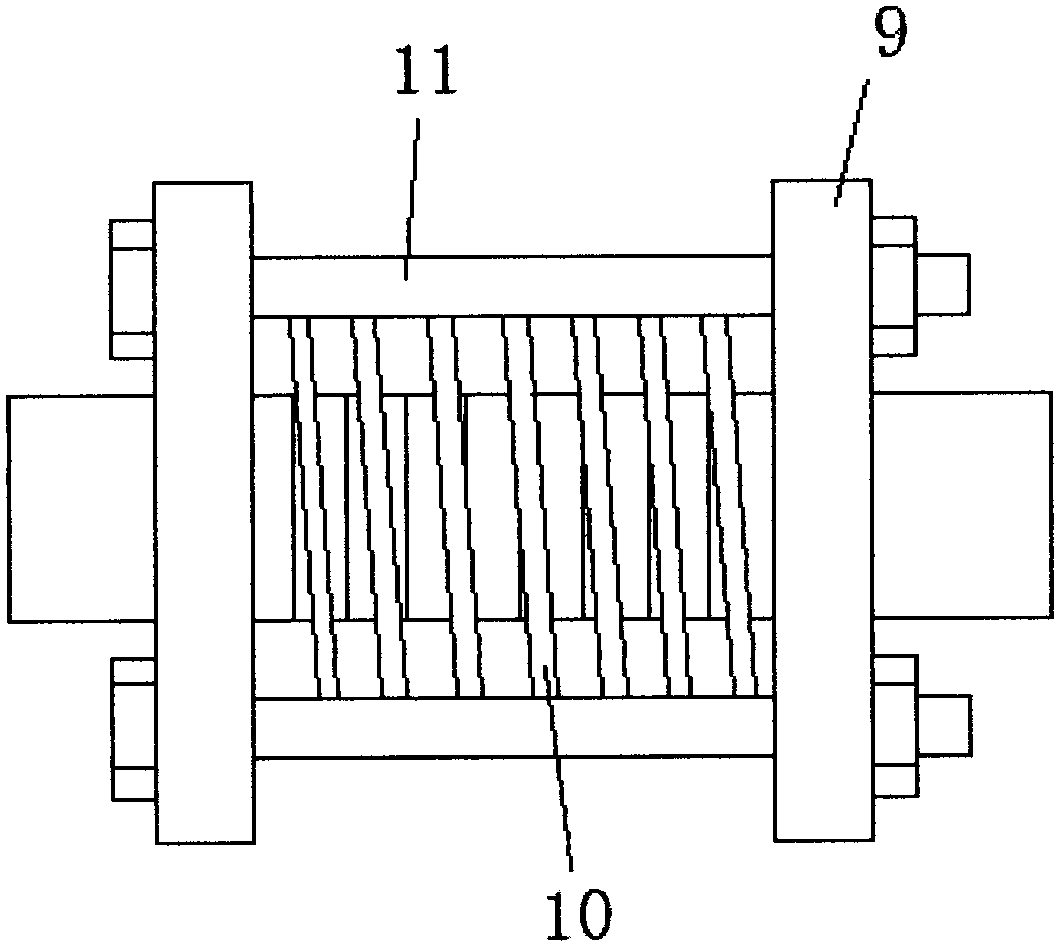

[0029] See attached Figure 1-3 , the anti-vibration heat dissipation system of a diesel locomotive includes a plurality of heat dissipation single sections 1, each heat dissipation single section 1 is a rectangular structure or a laminated structure, each heat dissipation single section 1 includes a heat dissipation pipe 2 and a fin 3, and the two ends of the heat dissipation pipe 2 are respectively The liquid inlet 4 and the liquid outlet 5, the heat dissipation pipe 2 is interspersed in the fin 3 in a multi-bending manner, the liquid inlet 4 of the heat dissipation pipe 2 is connected with the heat exchanger outlet 6 of the internal combustion engine 13, and the liquid outlet of the heat dissipation pipe 2 5 forms a docking interface with the heat exchanger inlet 7 of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com