Endless rope traction monorail crane system

A monorail crane and infinite rope technology, which is applied to load hanging components, transportation and packaging, earth-moving drilling and mining, etc., can solve the problems of increasing transportation difficulty, increasing safety hazards, and complicated installation and use, reducing the number of manual reversing, The effect of solving transportation problems and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

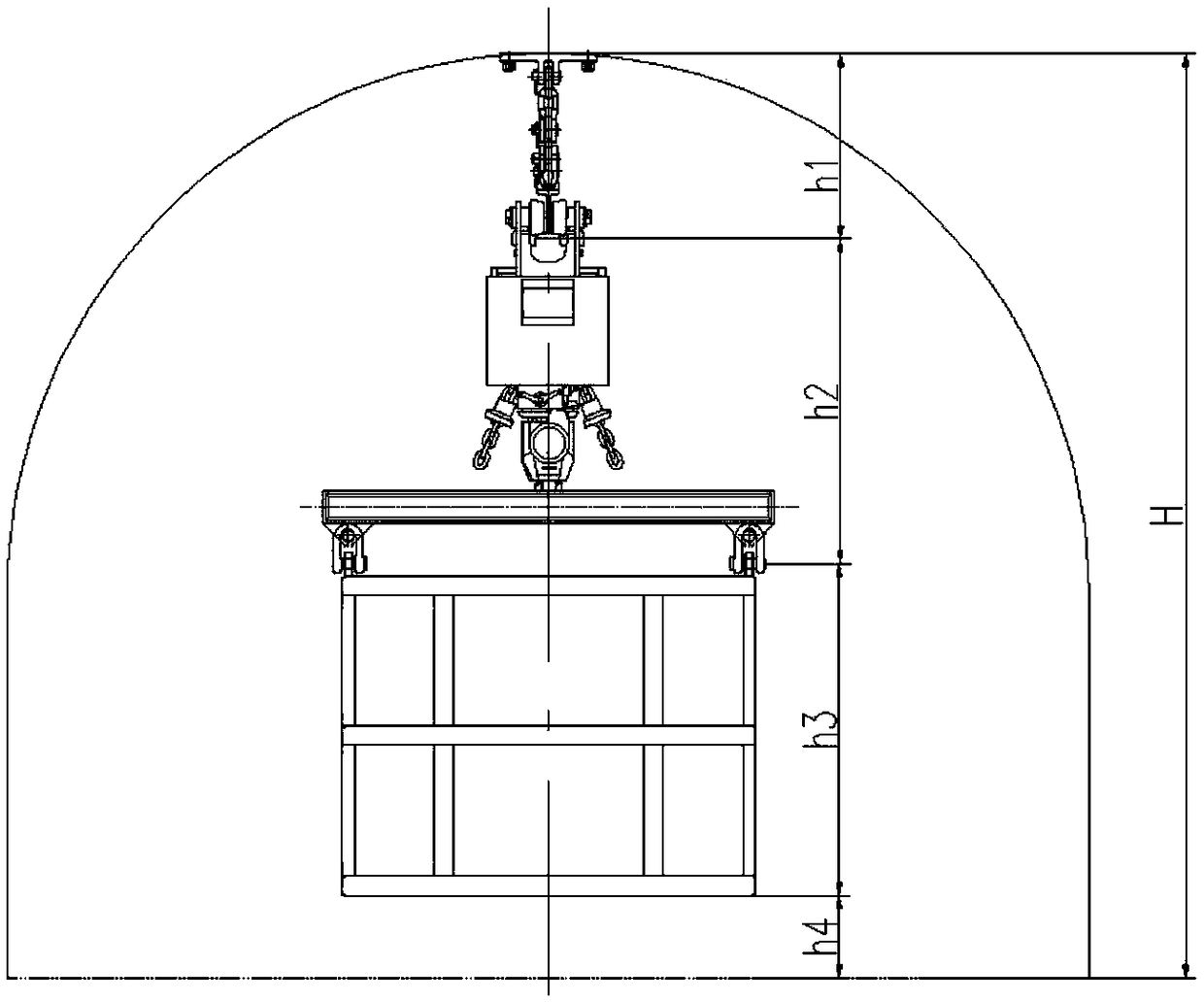

[0041] The general situation of the underground roadway in a coal mine is that the total length of the roadway is 1200 meters, the slope is 0-2° (the roadway basically has no slope, and there are errors in the laying of the monorail crane track), the height of the roadway is 2.3m, and the width is 3.6m. , the maximum cargo weight is 10 tons (no more than 12 tons), the height of the support is 900mm, and the roadway is basically a straight roadway with small bends in some parts.

[0042] The formula for calculating the traction force of the winch is as follows:

[0043] F=(G+G 0 )(0.02cosβ max +sinβ max )g+2μq R gL

[0044] In the formula: G0-the maximum transport weight is 12T;

[0045] βmax - the maximum slope of the running line is 2°;

[0046] μ-wire rope friction resistance coefficient 0.25;

[0047] qR- the weight of wire rope per unit length 1.74kg / m ( wire rope);

[0048] L-transport distance 1200m;

[0049] G - acceleration due to gravity;

[0050] Roadway ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com