Hydraulic micro-rotation safety joint for downhole tubular column

A technology for downhole pipe strings and safety joints, which is applied in the direction of drill pipes, casings, and drilling equipment. The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

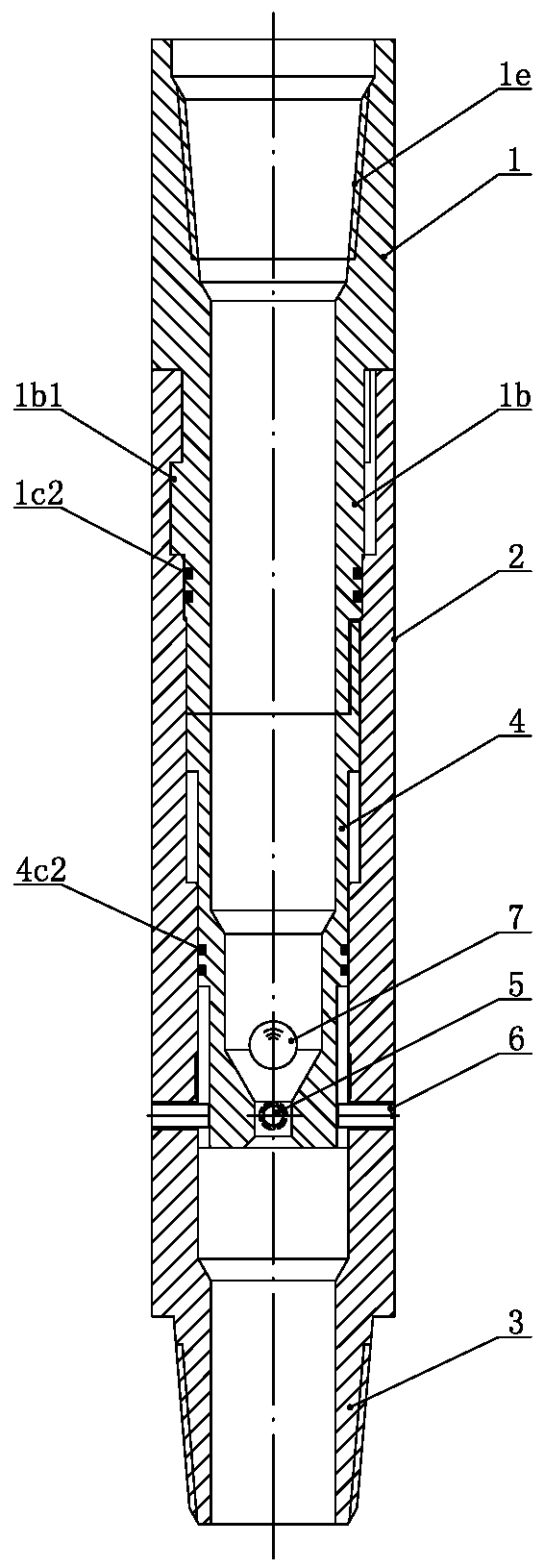

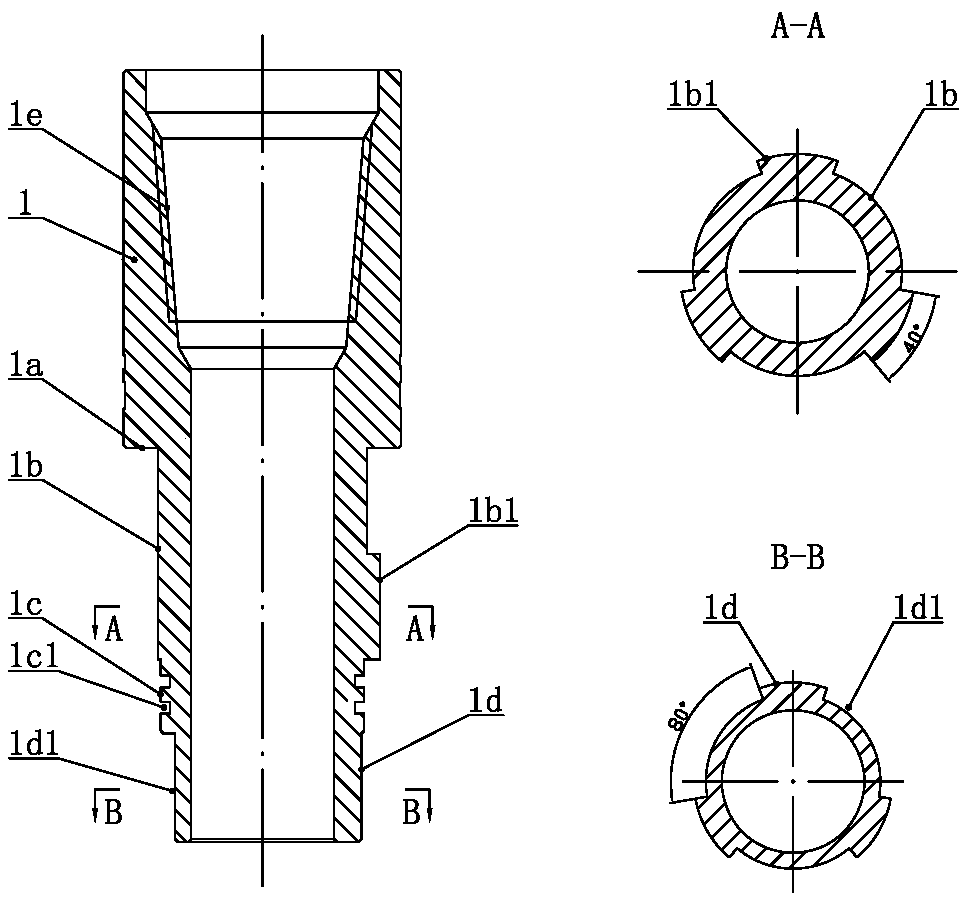

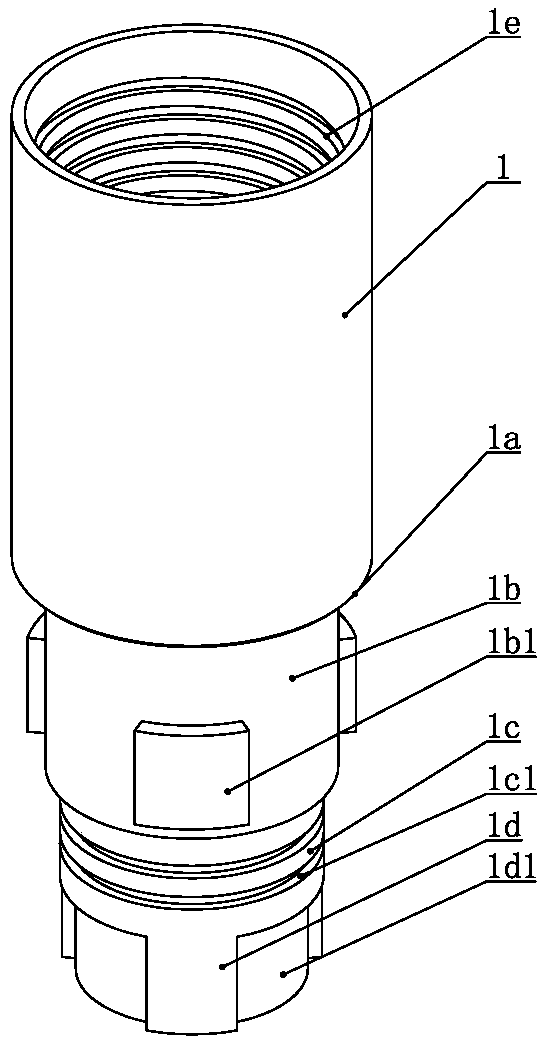

[0028] Such as Figure 1 to Figure 10 As shown, the hydraulic micro-twist safety joint for downhole pipe strings of the present invention includes an upper joint 1 and a lower joint 3, the upper inner cavity of the upper joint 1 is provided with a tapered female thread 1e that is screwed with the upper pipe string, and the lower joint 3 The outer end of the pipe is provided with a tapered male thread 3a which is screwed with the lower pipe string. The central holes of the upper joint 1 and the lower joint 3 are coaxial and communicate with each other. The upper end of the lower joint 3 is provided with a cylinder 2 extending upwards. The inner cavity of the cylinder 2 is equipped with a sliding sleeve that can slide axially along the inner wall of the cylinder 2. 4. The central hole of the sliding sleeve 4 gradually shrinks from top to bottom, and the lower end is provided with a bell-shaped ball seat 4d. The ball seat 4d is equipped with a steel ball 7 that can be closed. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com