Vertical construction joint construction method of post-casting strip

A technology of vertical construction joints and construction methods, applied in building components, building insulation materials, etc., can solve the problems of difficult formwork removal and easy leakage, and achieve the effect of solving difficult formwork support and preventing concrete slurry from overflowing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0027] In the present invention, the unit of all the numbers indicating the length without indicating the unit is mm.

[0028] This embodiment provides a method for constructing vertical construction joints of a post-cast belt, including the following steps:

[0029] First, the post-pouring belt construction section is selected on the reserved horizontal steel bar for pouring the horizontal concrete slab, and the horizontal steel bar is disconnected in the post-pouring belt construction section;

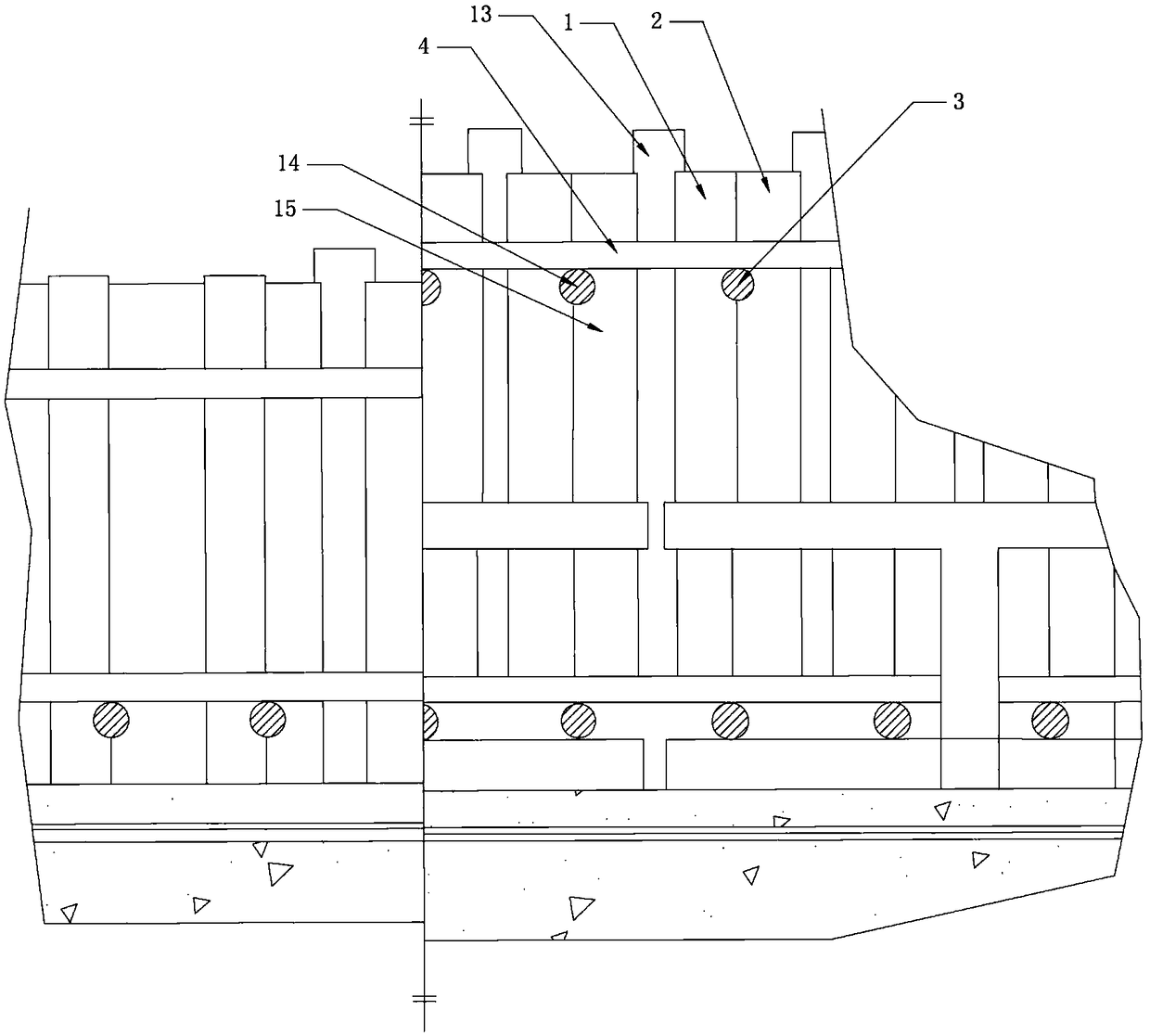

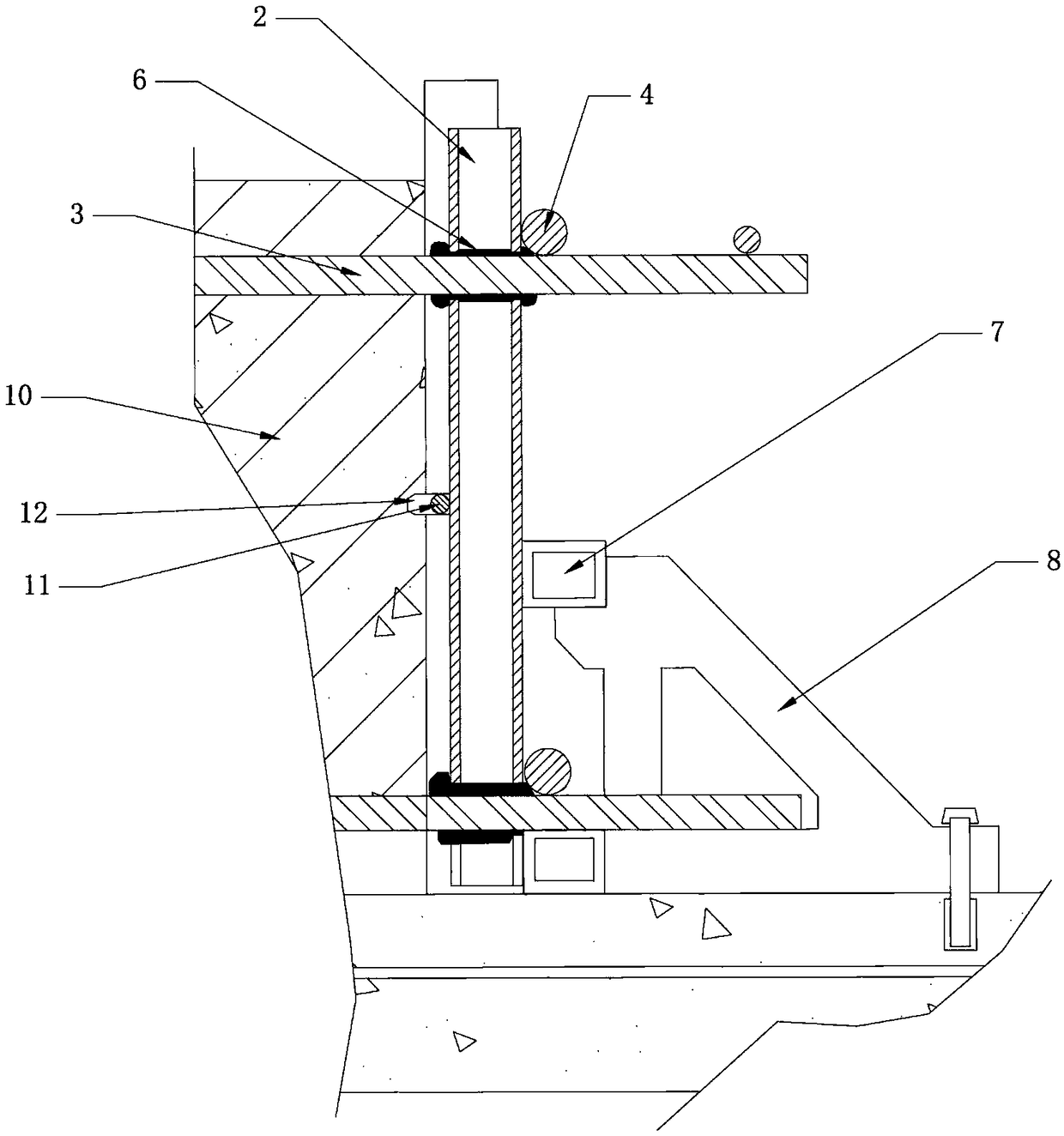

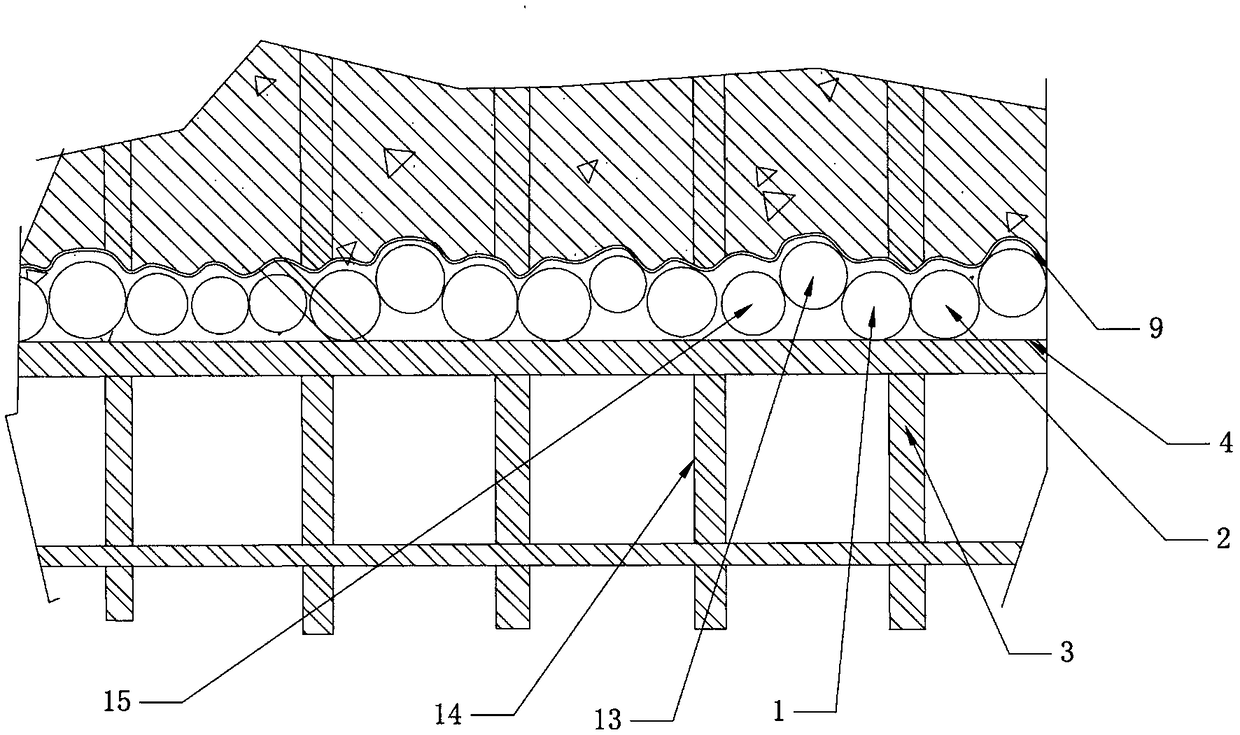

[0030] Specifically, such as figure 1 with figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com