Diamond-mounted gold watch case manufacturing process

A production process and technology for gold watches, applied in the field of diamond-encrusted gold watch case production process, can solve problems such as high cost, scratching, complicated fabrication process, etc., and achieve the effects of reduced surface resistivity, enhanced electrical conductivity, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

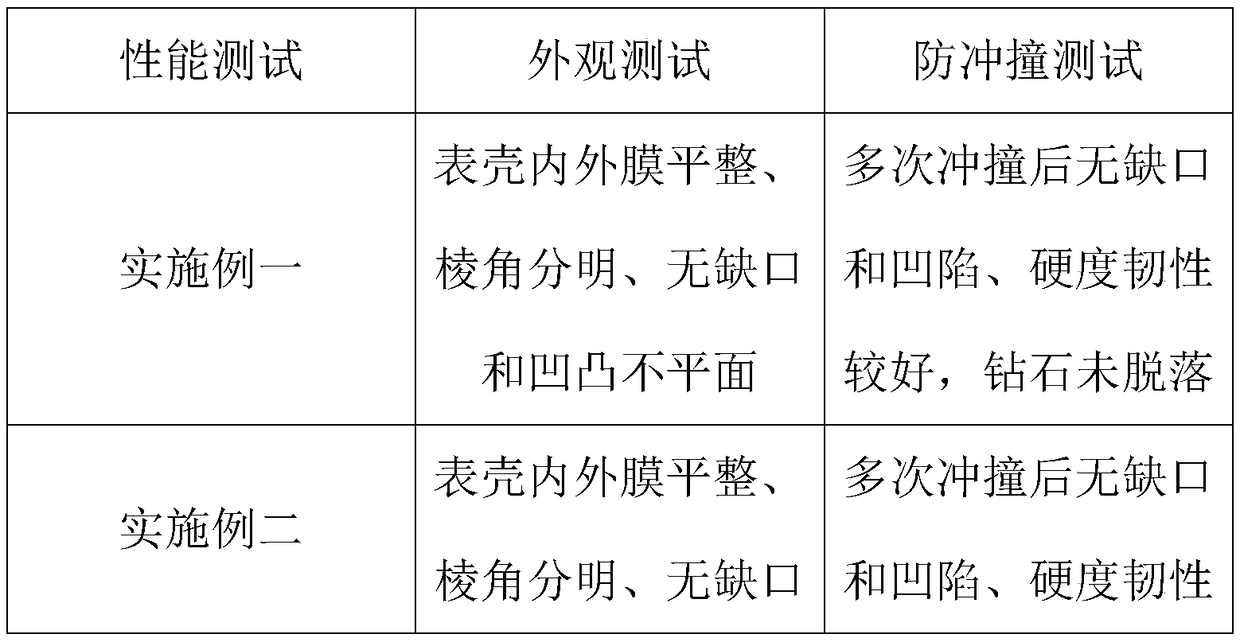

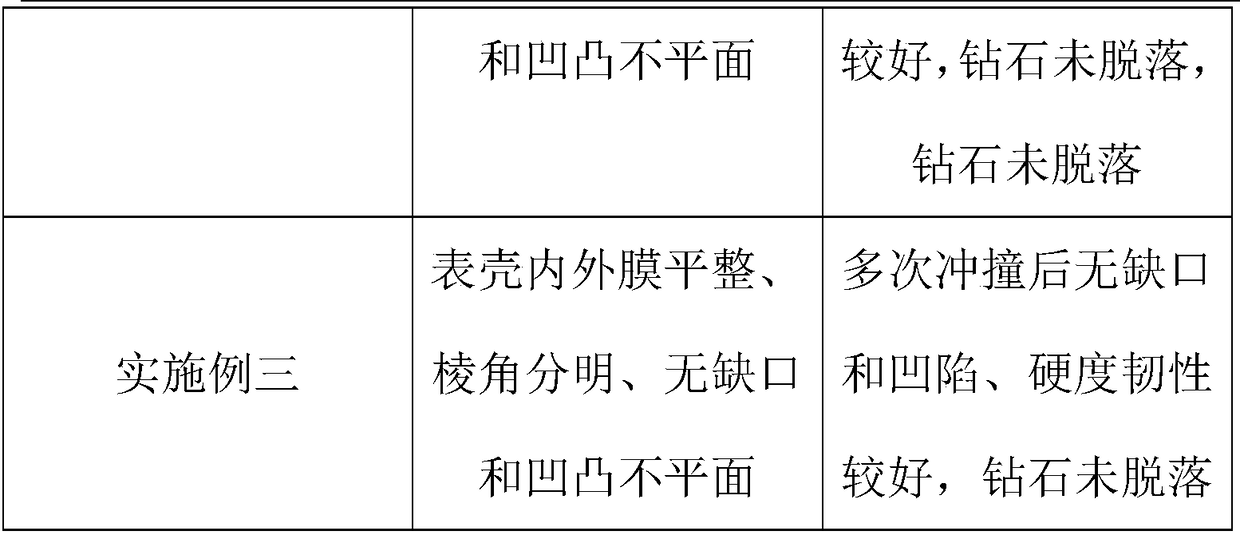

Embodiment 1

[0036] A manufacturing process of a gold watch case inlaid with diamonds, comprising the following steps:

[0037] S1, the preparation of gold case;

[0038] S2. Press the gold watch case prepared in step S1 into grooves at the parts of the gold watch case that need to be inlaid with diamonds;

[0039] S3. Apply insulating oil evenly on the inner surface of the gold case, add 2 microliters of conductive liquid to the groove of the gold case, and then place the diamond on the groove of the gold case with the conductive liquid at a temperature of 60°C Stand for 20 minutes, so that the part of the diamond located in the groove is covered with a uniform layer of conductive liquid;

[0040] S4. Place the watch case with diamonds prepared in step S3 on the rotating disk of the electroforming cylinder filled with electroforming liquid, so that the gold watch case is electroformed by rotating with the suspension at a certain speed during the electroforming process ; The rotating spe...

Embodiment 2

[0054] A manufacturing process of a gold watch case inlaid with diamonds, comprising the following steps:

[0055] S1, the preparation of gold case;

[0056] S2. Press the gold watch case prepared in step S1 into grooves at the parts of the gold watch case that need to be inlaid with diamonds;

[0057] S3. Apply insulating oil evenly on the inner surface of the gold case, add 4 microliters of conductive liquid to the groove of the gold case, and then place the diamond on the groove of the gold case with the conductive liquid at a temperature of 60-80°C Stand for 30 minutes under the same conditions, so that the part of the diamond located in the groove is covered with a uniform layer of conductive liquid;

[0058] S4. Place the watch case with diamonds prepared in step S3 on the rotating disk of the electroforming cylinder filled with electroforming liquid, so that the gold watch case is electroformed during the electroforming process with the suspension rotating at a certain...

Embodiment 3

[0072] A manufacturing process of a gold watch case inlaid with diamonds, comprising the following steps:

[0073] S1, the preparation of gold case;

[0074] S2. Press the gold watch case prepared in step S1 into grooves at the parts of the gold watch case that need to be inlaid with diamonds;

[0075] S3. Apply insulating oil evenly on the inner surface of the gold case, add 5 microliters of conductive liquid to the groove of the gold case, and then place the diamond on the groove of the gold case with the conductive liquid at a temperature of 80°C Stand for 40 minutes, so that the part of the diamond located in the groove is covered with a uniform layer of conductive liquid;

[0076] S4. Place the watch case with diamonds prepared in step S3 on the rotating disk of the electroforming cylinder filled with electroforming liquid, so that the gold watch case is electroformed during the electroforming process with the suspension rotating at a certain speed; The rotational speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com