Membrane thickness monitoring device and membrane formation equipment

A monitoring device and film thickness technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of large film thickness monitoring error, inaccurate film thickness monitoring, large rate fluctuation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

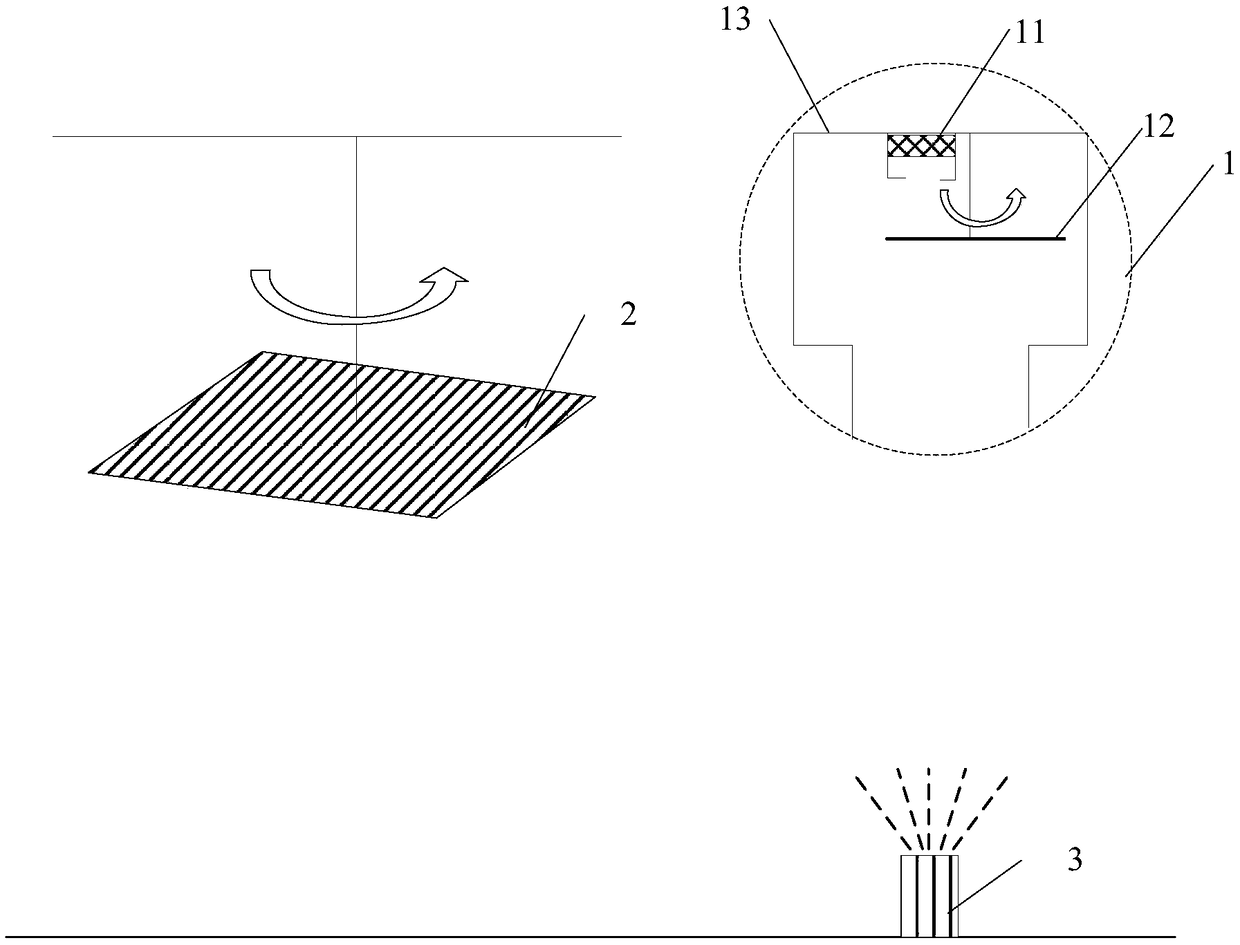

[0027] This embodiment provides a film thickness monitoring device. The film thickness monitoring device prolongs the service life of the crystal vibrating plate and improves the crystal vibrating plate on the premise of ensuring the accuracy of film thickness monitoring by adjusting the forming amount of the shielding plate and the film forming material. Use efficiency.

[0028] Such as figure 1 As shown, the film thickness monitoring device includes a film thickness synchronization unit, the film thickness synchronization unit includes a sensor 11 and a shutter 12 (Shutter), the shutter 12 is provided with a plurality of monitoring holes 121, the shutter 12 can move relative to the sensor 11, The orifices of at least two different monitoring holes 121 can be arranged opposite to the sensor 11 to monitor the amount of film-forming material passing through the monitoring holes 121 and reaching the sensor 11 within a set time.

[0029] When the film thickness monitoring device...

Embodiment 2

[0039] This embodiment also provides a film forming device, which can greatly improve the precision control of the film thickness by using the film thickness monitoring device in the first embodiment.

[0040] The film forming equipment includes a film forming material source and a film thickness monitoring device, such as figure 2 As shown, the film thickness monitoring device is the film thickness monitoring device 1 in Embodiment 1, and the film-forming material from the film-forming material source reaches the sensor 11 through the monitoring hole 121 of the blocking plate 12 .

[0041] As an example, the film-forming equipment can be, for example, evaporation equipment, which is adapted to the technological process of a modern production enterprise. The film-forming material source includes at least one evaporation crucible 3, and the evaporation crucible 3 is used to accommodate the evaporation material. Each plating crucible 3 is correspondingly provided with a film th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com