Low-viscosity and low-friction emulsified acid, method for preparing same and application of low-viscosity and low-friction emulsified acid

A technology of emulsified acid and emulsifier, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high viscosity of emulsified acid, achieve the effects of reducing friction, facilitating on-site construction, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

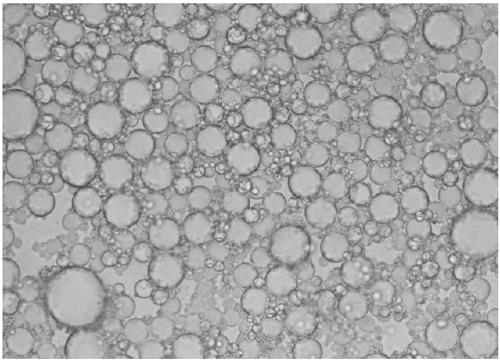

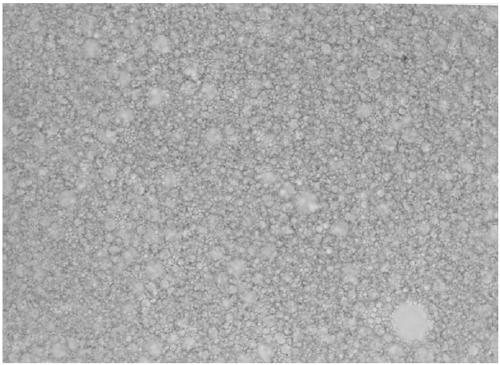

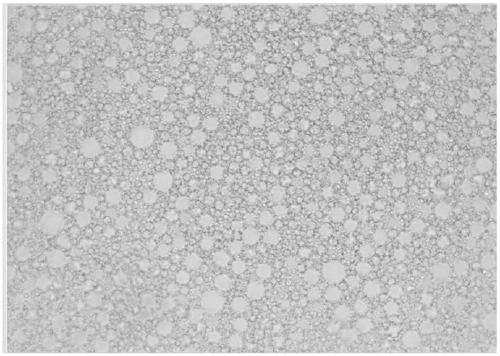

Image

Examples

Embodiment 1

[0043] This embodiment provides a low viscosity, low friction emulsified acid, the preparation method of which comprises the following steps:

[0044] Preparation of the acid phase:

[0045] Add 0.8 part of corrosion inhibitor and 1.0 part of iron ion stabilizer to 20 wt% hydrochloric acid, stir evenly to obtain acid phase.

[0046] Wherein, the corrosion inhibitor is a compound product of cinnamaldehyde, propargyl alcohol and methanol, and the mass ratio of the three is 20:10:70.

[0047] The iron ion stabilizer is sodium erythorbate.

[0048] Preparation of the oil phase:

[0049] to 0# Add 1.2 parts of emulsifier and 0.2 part of co-emulsifier to the diesel oil, and stir evenly to obtain an oil phase.

[0050] Wherein, the emulsifier is oleic acid diethanolamide, and the co-emulsifier is laurylamine.

[0051] Preparation of emulsified acid (acid oil volume ratio 70:30):

[0052] Stir the oil phase at a stirring speed of 300r / min, slowly pour the acid phase into the oil ...

Embodiment 2

[0054] This embodiment provides a low viscosity, low friction emulsified acid, the preparation method of which comprises the following steps:

[0055] Preparation of the acid phase:

[0056] Add 1.0 parts of corrosion inhibitor and 1.5 parts of iron ion stabilizer to 28wt% hydrochloric acid, stir evenly to obtain acid phase.

[0057] Wherein, the corrosion inhibitor is a compound product of cinnamaldehyde, propargyl alcohol and methanol, and the mass ratio of the three is 20:10:70.

[0058] The iron ion stabilizer is sodium erythorbate.

[0059] Preparation of the oil phase:

[0060] To -10 # Add 1.5 parts of emulsifier and 0.3 parts of co-emulsifier to the diesel oil, and stir evenly to obtain an oil phase.

[0061] Wherein, the emulsifier is oleic acid diethanolamide, and the co-emulsifier is laurylamine.

[0062] Preparation of emulsified acid (acid oil volume ratio 70:30):

[0063] Stir the oil phase at a stirring speed of 400r / min, slowly pour the acid phase into th...

Embodiment 3

[0065] This embodiment provides a low viscosity, low friction emulsified acid, the preparation method of which comprises the following steps:

[0066] Preparation of the acid phase:

[0067] Add 0.8 part of corrosion inhibitor and 1.0 part of iron ion stabilizer to 20 wt% hydrochloric acid, stir evenly to obtain acid phase.

[0068] Wherein, the corrosion inhibitor is a compound product of cinnamaldehyde, propargyl alcohol and methanol, and the mass ratio of the three is 20:10:70.

[0069] The iron ion stabilizer is sodium erythorbate.

[0070] Preparation of the oil phase:

[0071] To -20 # Add 1.3 parts of emulsifier and 0.4 parts of co-emulsifier to the diesel oil, and stir evenly to obtain an oil phase.

[0072] Wherein, the emulsifier is oleic acid diethanolamide, and the co-emulsifier is laurylamine.

[0073] Preparation of emulsified acid (acid oil volume ratio 80:20):

[0074] Stir the oil phase at a stirring speed of 300r / min, slowly pour the acid phase into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com