High-strength and high-water-resistance polymer emulsion building waterproof coating and preparation method thereof

A technology of polymer emulsion and building waterproofing, applied in the direction of coating, etc., can solve the problems of easy falling of construction roller coating, low tensile strength, poor adhesion, etc., to solve the problem of no strength, reduce water absorption, strength small loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

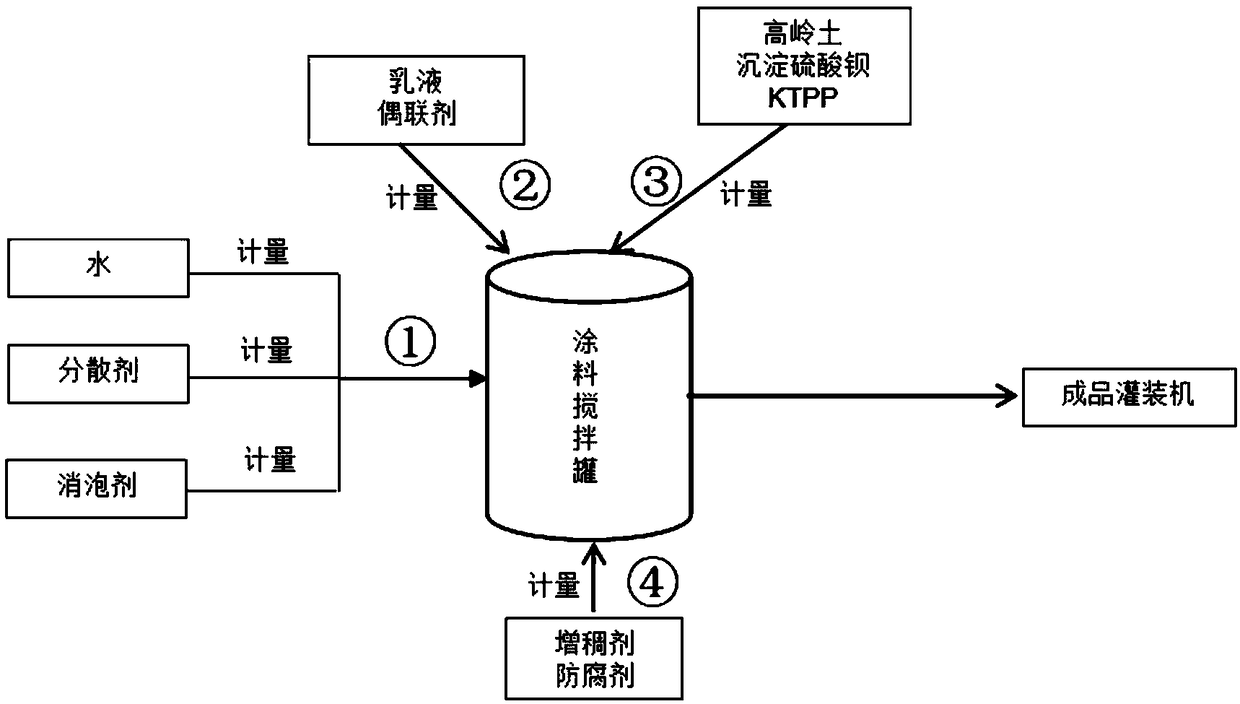

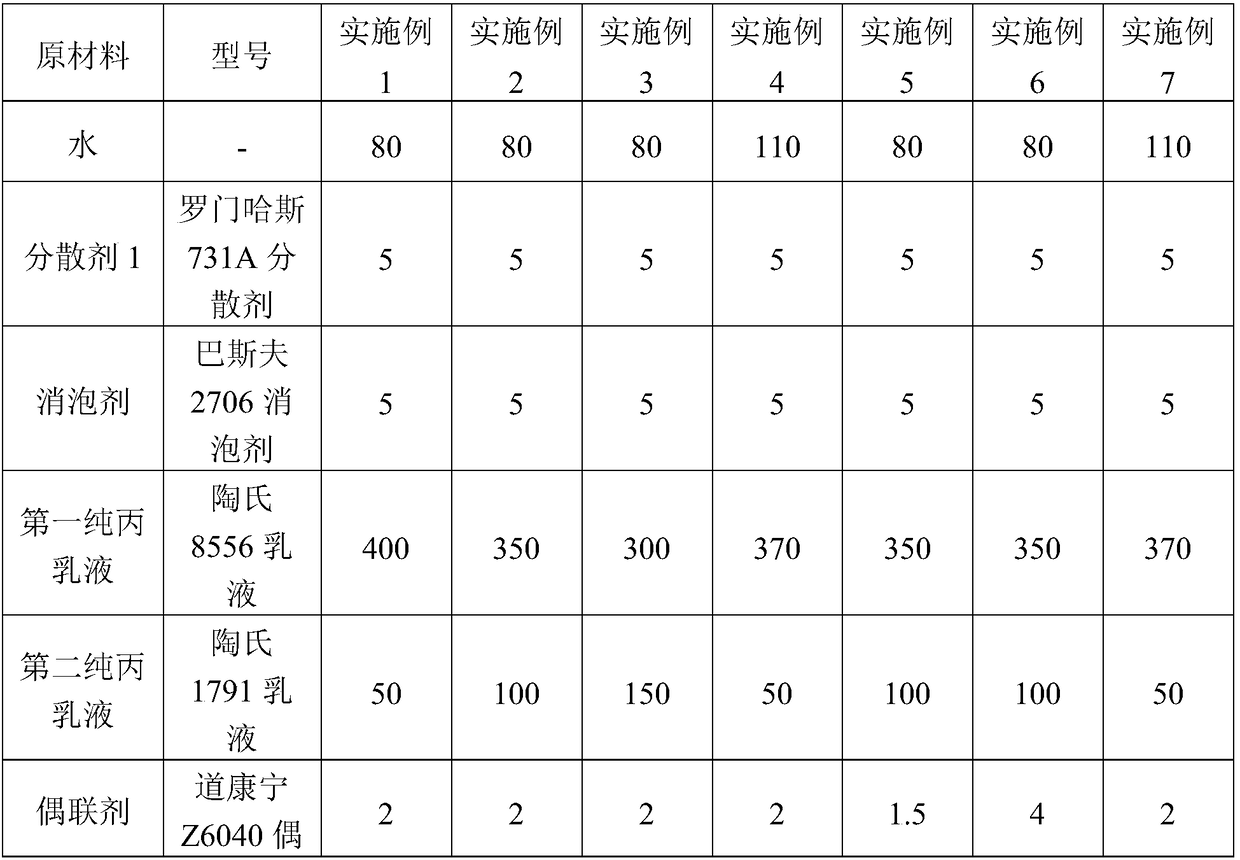

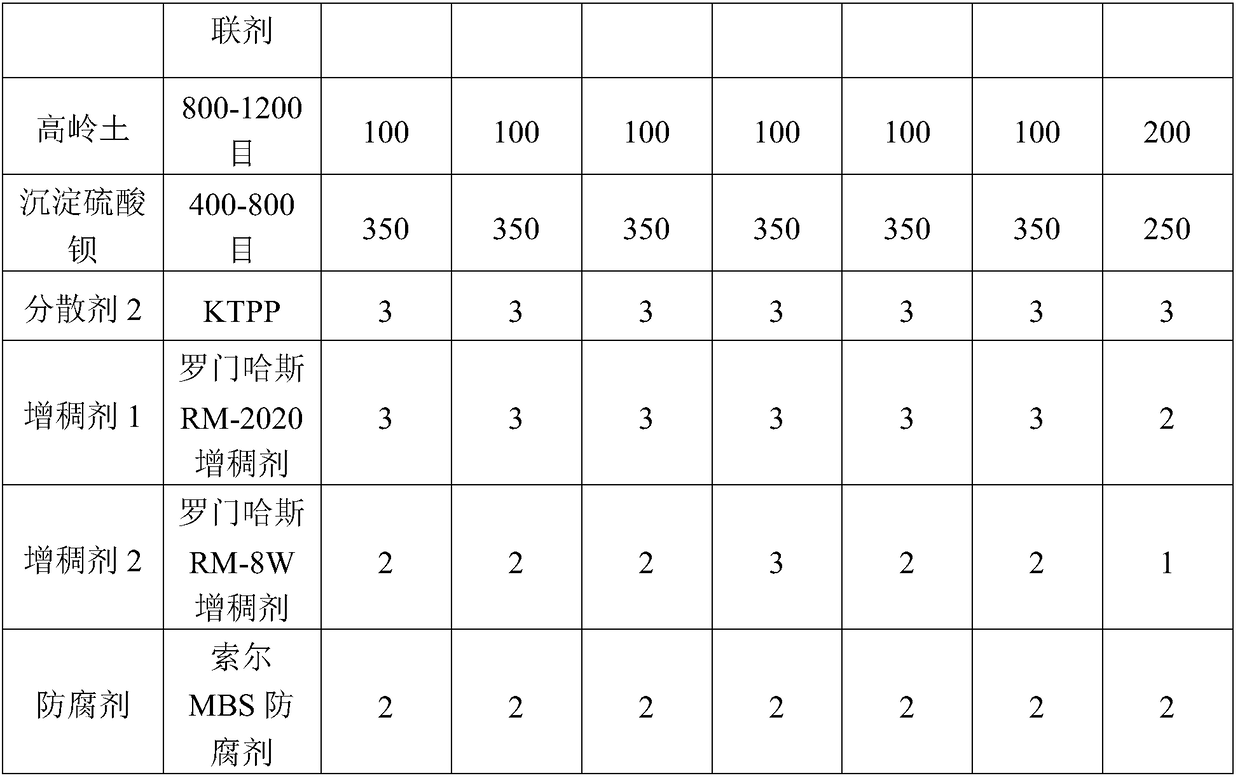

[0065] ① if figure 1 As shown, measure deionized water, Rohm and Haas 731A dispersant, and BASF 2706 defoamer into the liquid material mixing tank, turn on the disperser in the mixing tank, adjust the speed at 300r / min, and stir for 2 minutes.

[0066] ② Measure Dow 8556 Emulsion, Dow 1791 Emulsion and Dow Corning Z6040 Coupling Agent, add it into the liquid material mixing tank, adjust the speed to 500r / min and stir for 5 minutes.

[0067] ③ Measure kaolin, precipitated barium sulfate, and industrial grade potassium tripolyphosphate KTPP and slowly add to the mixing tank, adjust the speed to 800r / min and stir for 10 minutes.

[0068] ④ Measure Rohm and Haas RM-8W thickener, Rohm and Haas RM-2020 thickener, and Sol MBS preservative, add it to the liquid material mixing tank and keep stirring at 800r / min for 5 minutes.

[0069] ⑤ Reduce the rotation speed to 300r / min and stir for 3 minutes to mechanically defoam to obtain a one-component waterproof coating for finished product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com