A kind of processing method of chlorine dioxide generator reactor

A chlorine dioxide and processing method technology, applied in the directions of chlorine dioxide, chlorine oxide, adhesive additives, etc., can solve the problems of plastic changes of connecting pipes, easy cracking at welds, weak connections, etc., and achieve increased service life, The effect of improving production efficiency and reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

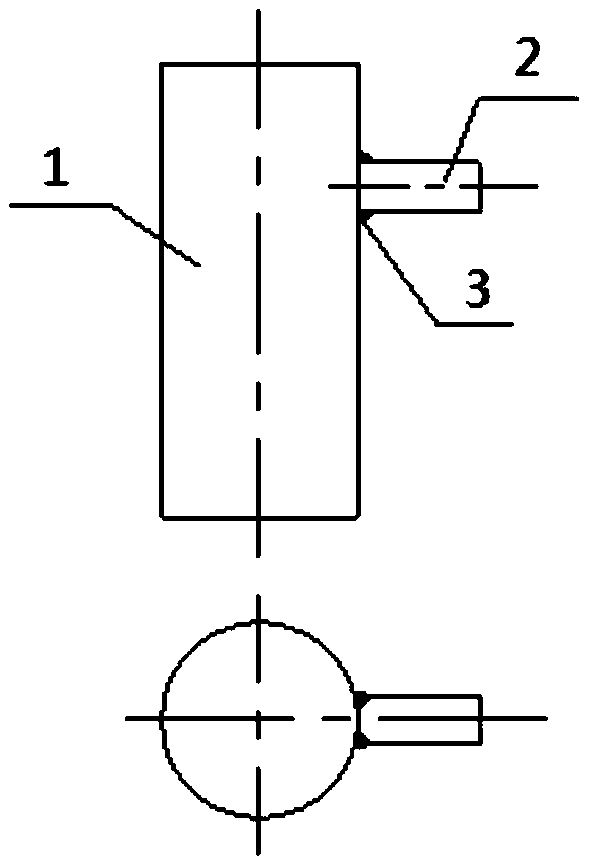

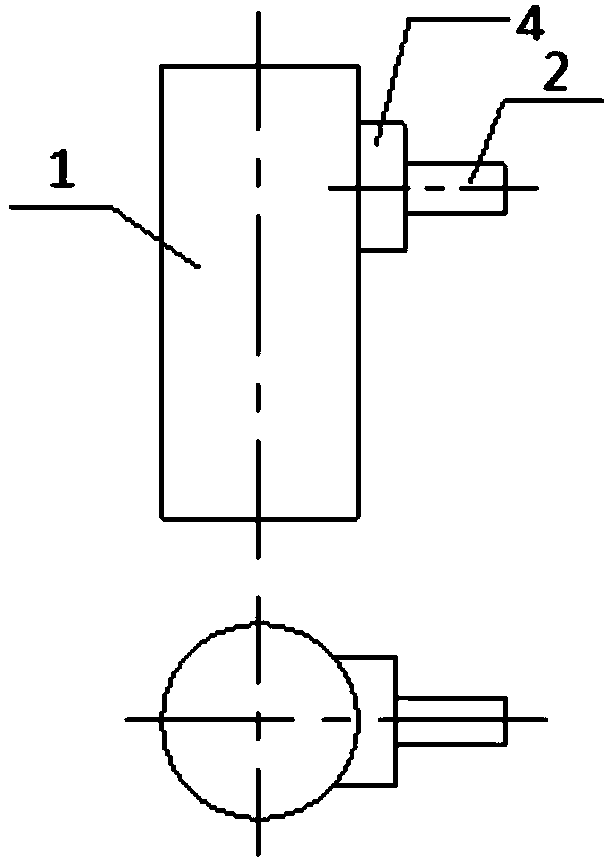

Image

Examples

Embodiment 1

[0038] The present embodiment provides a kind of processing method of chlorine dioxide generator reactor, comprises the following steps:

[0039] Step A, the workpiece surface is polished successively, and acetone is used for cleaning operation and chemical reagent surface treatment; chemical reagent treatment adopts chromic acid method: potassium dichromate (g): water (ml): concentrated sulfuric acid (ml)=1: 2:20;

[0040] Step B, coating the adhesive on the surface of the workpiece after pretreatment, the thickness of the adhesive coating on the surface of the workpiece is 3-5mm;

[0041] Step C: butt the surfaces of the two workpieces that need to be bonded, and carry out bonding and curing through pressurization and heating operations; apply pressure to generate a 0.2MPa opposite vertical pressure between the surfaces of the two workpieces; the heating process is: at 5°C / Raise the temperature to 40°C and stay at 40°C for 10 minutes; then raise the temperature to 50°C at ...

Embodiment 2

[0052] The present embodiment provides a kind of processing method of chlorine dioxide generator reactor, comprises the following steps:

[0053] Step A, the workpiece surface is polished successively, and acetone is used for cleaning operation and chemical reagent surface treatment; chemical reagent treatment adopts chromic acid method: potassium dichromate (g): water (ml): concentrated sulfuric acid (ml)=1: 2:20;

[0054]Step B, coating the adhesive on the surface of the workpiece after pretreatment, the thickness of the adhesive coating on the surface of the workpiece is 3-5mm;

[0055] Step C: butt the surfaces of the two workpieces that need to be bonded, and carry out bonding and curing through pressurization and heating operations; apply pressure to generate a vertical pressure of 0.2-0.5 MPa between the surfaces of the two workpieces; the heating process is: 5 ℃ / min to 40°C, stay at 40°C for 10 minutes; then raise the temperature to 50°C at 2°C / min, stay for 10 minute...

Embodiment 3

[0066] The present embodiment provides a kind of processing method of chlorine dioxide generator reactor, comprises the following steps:

[0067] Step A, the workpiece surface is polished successively, and acetone is used for cleaning operation and chemical reagent surface treatment; chemical reagent treatment adopts chromic acid method: potassium dichromate (g): water (ml): concentrated sulfuric acid (ml)=1: 2:20;

[0068] Step B, coating the adhesive on the surface of the workpiece after pretreatment, the thickness of the adhesive coating on the surface of the workpiece is 3-5 mm;

[0069] Step C: butt the surfaces of the two workpieces that need to be bonded, and carry out bonding and curing through pressurization and heating operations; apply pressure to generate a vertical pressure of 0.2-0.5 MPa between the surfaces of the two workpieces; the heating process is: 5 ℃ / min to 40°C, stay at 40°C for 10 minutes; then raise the temperature to 50°C at 2°C / min, stay for 10 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com