All-soft underwater robot driven by chemical exergonic reaction and experimental platform thereof

An underwater robot, energy-releasing reaction technology, applied in underwater operation equipment, fluid dynamics test, testing of machine/structural components, etc. The effect of fast, high average speed and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

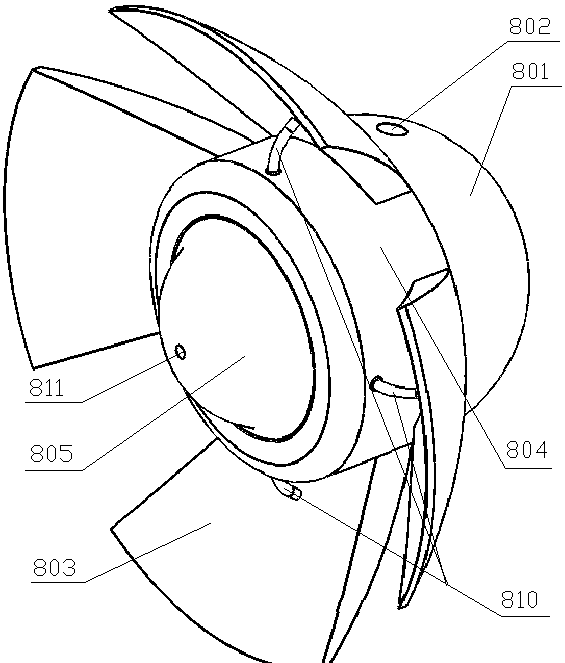

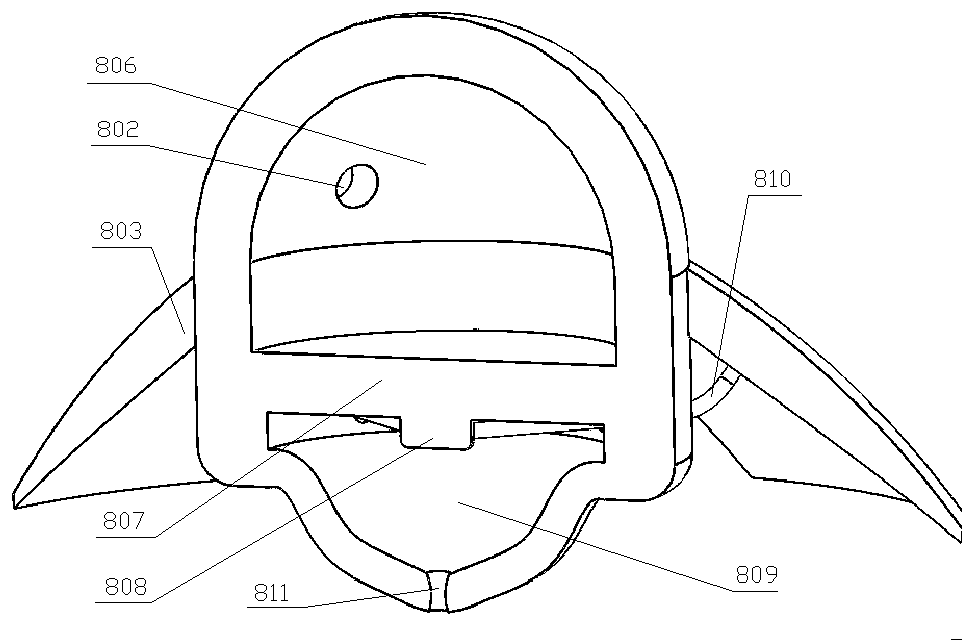

[0027] As shown in the figure, a fully soft underwater robot driven by a chemical release energy reaction includes a body, which includes a variable stiffness head 801, a variable stiffness body 804, and an arc-shaped tail 805 connected in sequence, and the variable stiffness head 801 is provided with The trachea interface 802, the variable stiffness body 804 is provided with flexible wings 803, and the arc-shaped tail 805 is provided with injection holes 811 and transmission holes 812;

[0028] The interior of the main body includes a reaction chamber 806, a flexible driving membrane 807 and a water storage and injection chamber 809 connected in sequence. The flexible driving membrane 807 is provided with a flexible joint 808, and the flexible joint 808 is provided with a flexible bone 810 to connect with the flexible wing 803.

[0029] As a preferred structure, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com