Heating sheet for tire repairing

A heating pad and tire technology, applied in the field of tire repair, can solve the problems of inability to heat the patch, the patch is easy to fall off, and the patch vulcanization effect is not good, and achieves the effect of reasonable design, simple structure, and guaranteed vulcanization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

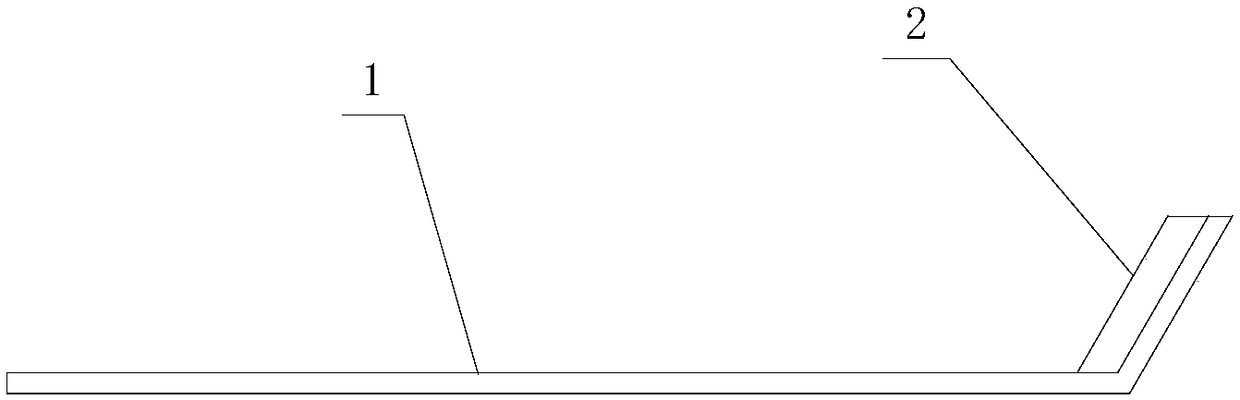

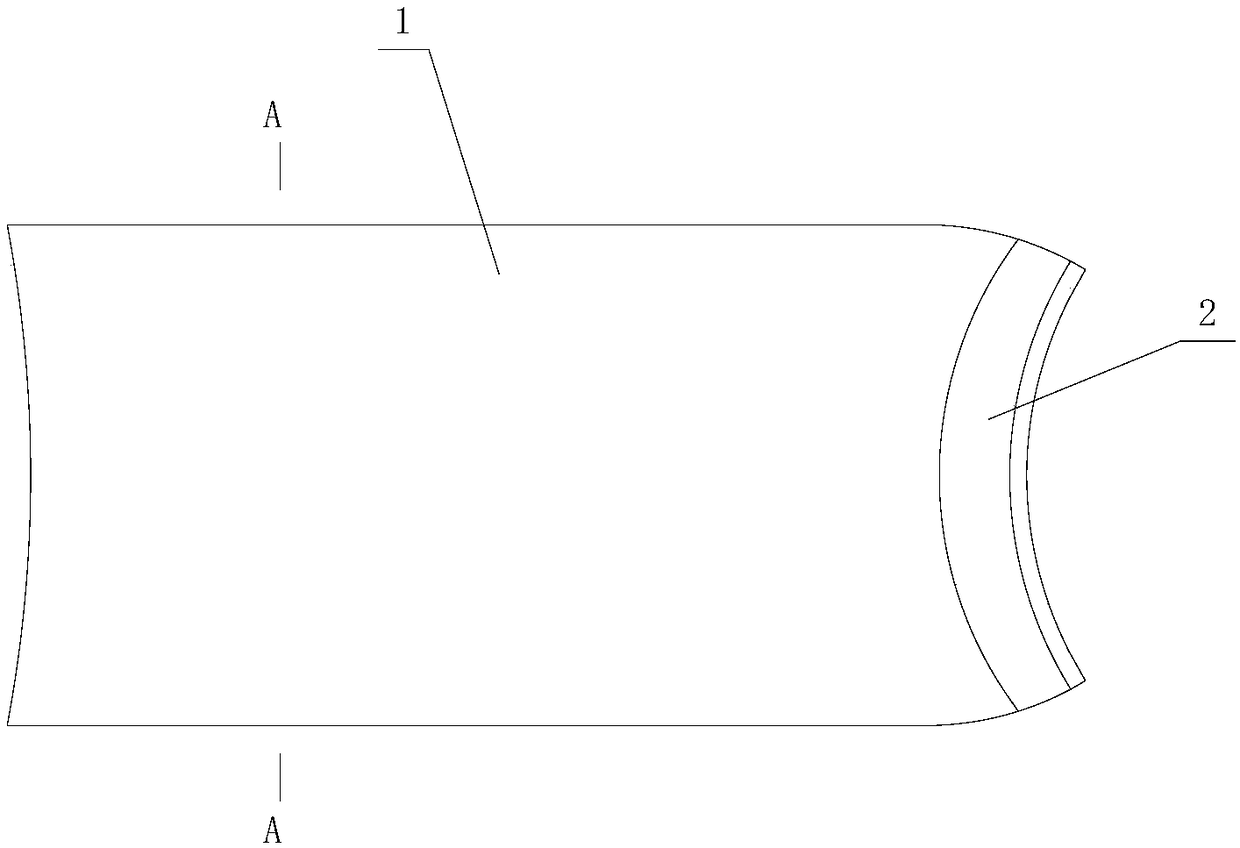

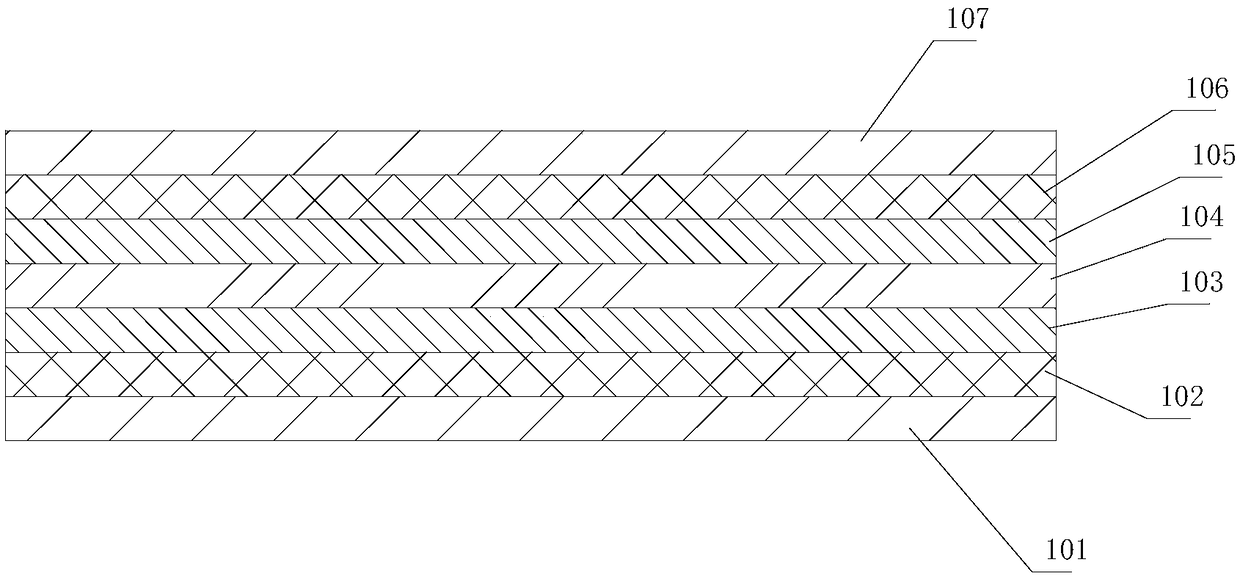

[0024] Such as Figure 1 to Figure 5 As shown, a heating sheet for tire repair includes a heating sheet main body 1, the left end of the heating sheet main body 1 is an arc-shaped surface concave inward, and the right end is provided with an arc-shaped flange 2, and the arc-shaped flange 2 It is an arc-shaped component arranged along the width direction of the heating chip main body, and the center of the arc-shaped component is located outside the heating chip main body 1, that is, the circle center of the arc-shaped component is located outside the right end of the heating chip main body 1.

[0025] The root of the arc-shaped flange 2 is smoothly transitioned to the main body 1 of the heating sheet. Specifically, the width dimension of the right end of the heating sheet main body gradually decreases, and the two sides of the right end of the heating sheet main body 1 and the root of the arc-shaped flange transition smoothly.

[0026] The included angle between the arc-shape...

Embodiment 2

[0030] join Figure 6 The difference between this embodiment and the first embodiment is that arc-shaped flanges 2 are provided on the left and right ends of the heating chip main body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com