Preparing method for wire coating layer

A covering layer and electric wire technology, which is applied in the field of wire covering layer preparation, can solve problems such as increasing the shape of the covering layer, breaking copper wires, and deforming the covering layer, and achieves simple processing, extended service life, and wide application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

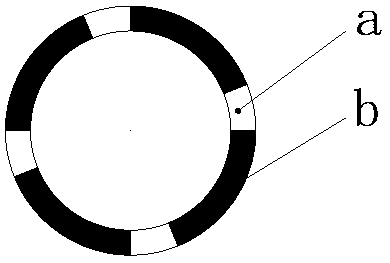

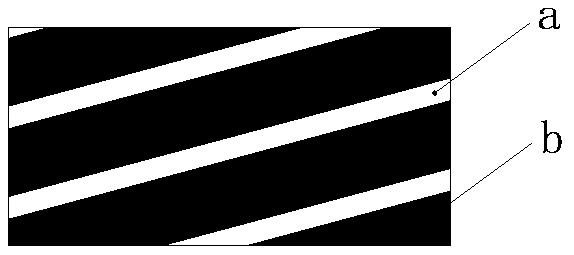

[0026] see figure 1 Shown is a kind of wire covering layer preparation method, and concrete steps are as follows:

[0027] 1) Use different materials to prepare the same layer of cladding layer

[0028] Before the preparation, use the software to slice the 3D model of the designed cladding layer. The thickness of each layer of the slice is the thickness of the cladding layer of the CMT layer. Then, according to the sliced path, the walking path of each layer is generated into the program code. , which are sequentially imported into the CMT control system, and then prepared:

[0029] Clean the surface of the mold for preparing the wire covering layer, and wipe the surface of the mold; then pile up thermoplastic b on the surface of the mold in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com