Full-electric servo intelligent butt fusion welding machine, system and method

A hot-melt docking and electric servo technology, applied in other home appliances, home appliances, applications, etc., can solve the problems of non-standard hot-melt distance and difficult to find, and achieve the effect of remote judgment and control and improved reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] This embodiment provides an all-electric servo intelligent butt fusion welding machine. The all-electric servo intelligent butt fusion welding machine is suitable for construction sites where two thermoplastic pipes need to be welded butt welded. It is easy to carry and precisely controls the butt joint distance. advantage. Specifically, as figure 1 and figure 2 As shown, the all-electric servo intelligent butt fusion welding machine includes:

[0074] The left frame 1 is provided with a first fixing fixture disc 2;

[0075] Right frame 3, between left frame 1 and right frame 3, is respectively connected with fixed bar 4 and gear bar 5;

[0076] The second fixing fixture disk 6 is fixedly arranged on the fixing rod 4 and is located on the right side of the first fixing fixture disk 2;

[0077] The first sliding fixture disk 7 and the second sliding fixture disk 8 are sleeved on the fixed rod 4 left and right, and are all located on the right side of the second fixe...

Embodiment 2

[0115] This embodiment provides a method for an all-electric servo intelligent butt fusion welding machine, using the all-electric servo intelligent butt fusion butt welding machine described in Embodiment 1, and specifically expounds the method for the fusion welding machine.

[0116] Specifically, as image 3 As shown, the method includes a hot-melt butt detection step, a data judgment step and a data feedback step; the hot-melt butt detection step includes the following sub-steps:

[0117] The first thermoplastic pipe and the second thermoplastic pipe after the hot-melt heating are completed by the hot plate are hot-melt butt jointed under the action of the servo motor 11; wherein the first thermoplastic pipe passes through the first fixing fixture disc 2 and the second fixing fixture The disc 6 is fixed, and the second thermoplastic pipe is fixed by the first sliding clamp disc 7 and the second sliding clamp disc 8;

[0118] In the process of hot-melt butt jointing, the f...

Embodiment 3

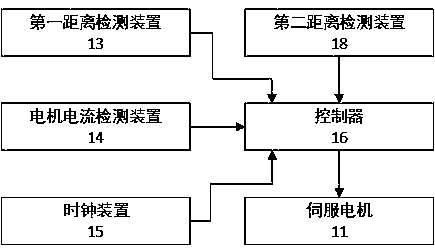

[0135] Based on the realization of embodiment 1, this embodiment also provides an all-electric servo intelligent butt fusion welding machine system, such as Figure 4 As shown, it includes the all-electric servo intelligent butt fusion butt welding machine; the all-electric servo intelligent butt fusion butt welding machine also includes:

[0136] A temperature detection device 23 is connected with the controller 16 for collecting temperature data;

[0137] The first data transmission device 19 is bidirectionally connected with the controller 16 for uploading welding data and receiving judgment data, the welding data including temperature data and distance data;

[0138] Described system also comprises cloud server 24, and described cloud server 24 comprises:

[0139] The second data transmission device 20 is used for data interaction with the all-electric servo intelligent butt fusion welding machine;

[0140] Large welding database 21, used to store welding data of all all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com