Multi-process integrated robot device

A robot and multi-process technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of small application range, reduce the transfer time, improve work efficiency, and realize the effect of automatic action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

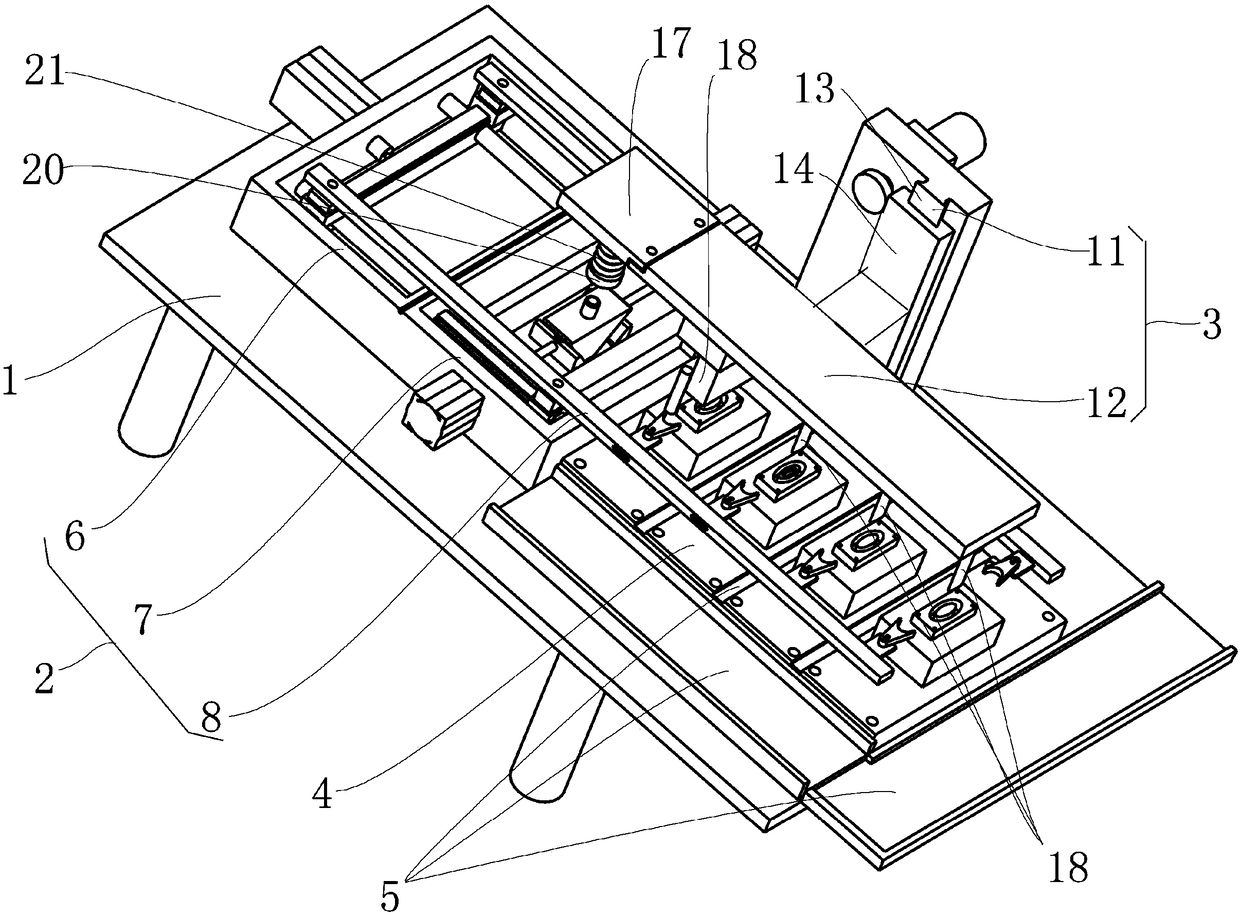

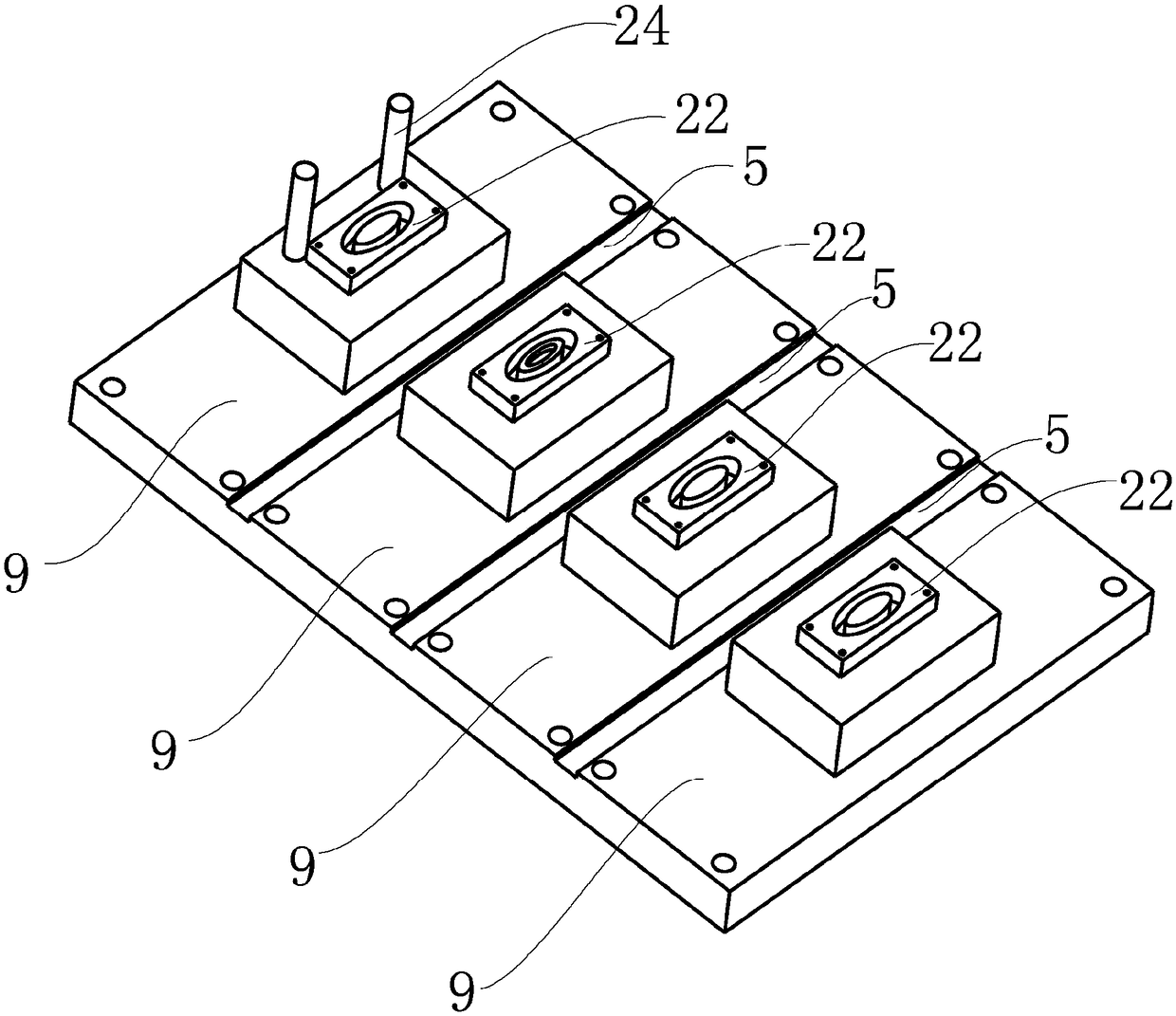

[0035] A multi-process integrated robot device in the embodiment of the present invention, such as figure 1 , figure 2 and image 3 As shown, it includes: a base 1, a slider driving part 2, a movable working part 3 and a material mold table 4, and the slider driving part 2, the movable working part 3 and the material mold table 4 are arranged on the upper part of the base 1;

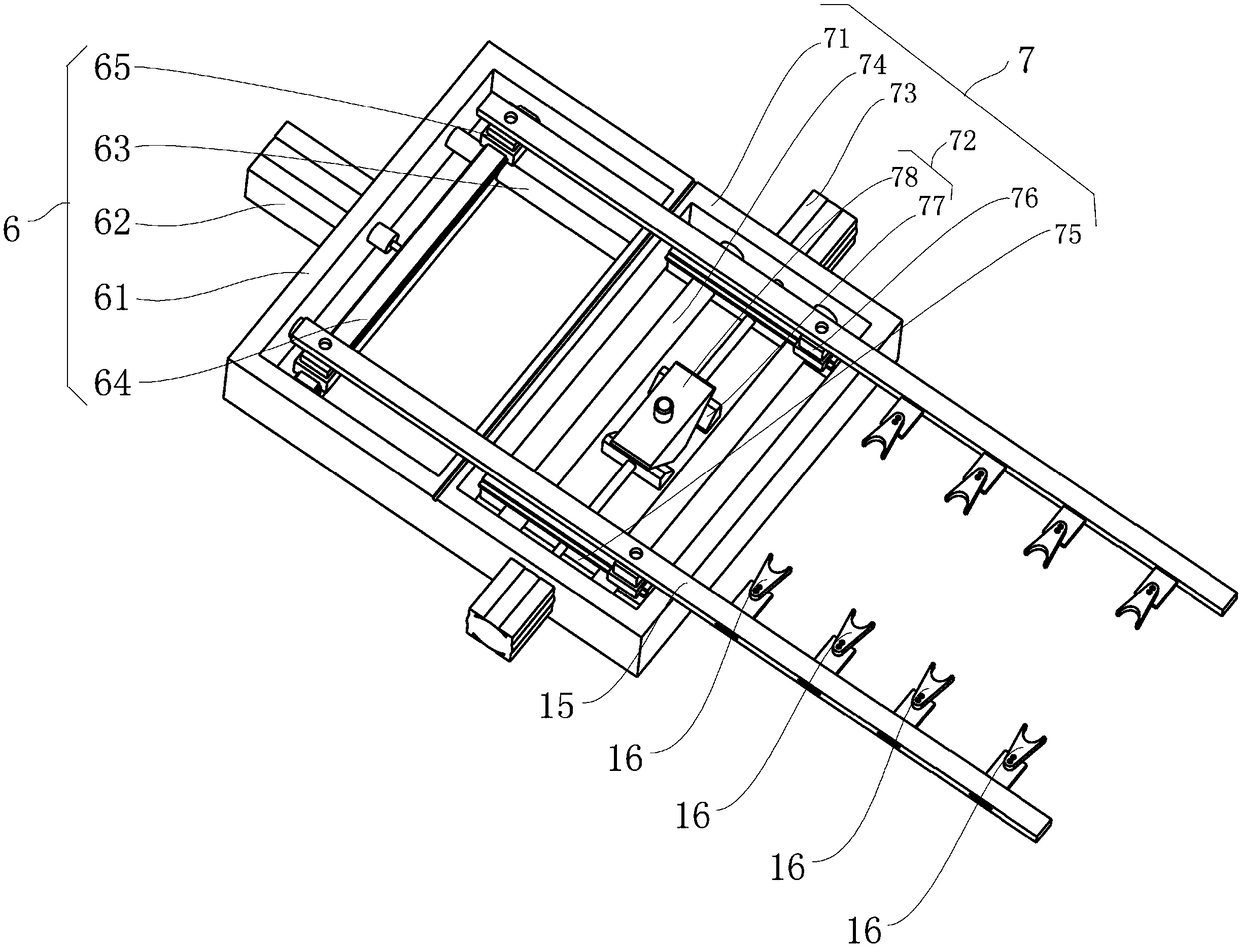

[0036] The slider drive part 2 includes a transverse drive part 6, a longitudinal drive part 7 and a material clamping device 8, the transverse drive part 6 is used to drive the material clamping device 8 to move laterally, and the longitudinal drive part 7 is used to drive the material clamping device 8 to move longitudinally. Movement: the transverse driving part 6 and the longitudinal driving part 7 are arranged side by side, and the material clamping device 8 includes two clamping arms 15 arranged in parallel on the upper part of the transverse driving part 6 and the longitudinal driving part 7. Th...

Embodiment 2

[0048] Compared with Embodiment 1, in Embodiment 2, a limit sensing device 24 is also provided on one of the mold parts 9, and the limit sensing device 24 is used to limit the lowest position of the downward movement of the die device 12. In this embodiment, The limit sensing device 24 uses a pressure sensor to realize the limit function, which has good sensitivity and reliability.

Embodiment 3

[0050] Compared with embodiment 1, on the basis of embodiment 1, embodiment 3 is provided with a pressure rod spring 21 on the top block pressure rod 20, and the pressure rod spring 21 is used for buffering, so that it will not be damaged during actual operation. The wedge-shaped top block 77 and the wedge-shaped pressing block 78 cause unnecessary damage and improve the service life of parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com