Six-degree-of-freedom attitude adjustment docking platform

A technology for docking platforms and degrees of freedom, applied in workbenches, manufacturing tools, etc., can solve the problems of difficulty in compressing the dimension space in the height direction, increasing the size and quality of the shafting space, hindering the improvement of platform performance, and achieving dynamic performance improvement. , Conducive to the effect of high size compression and good balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

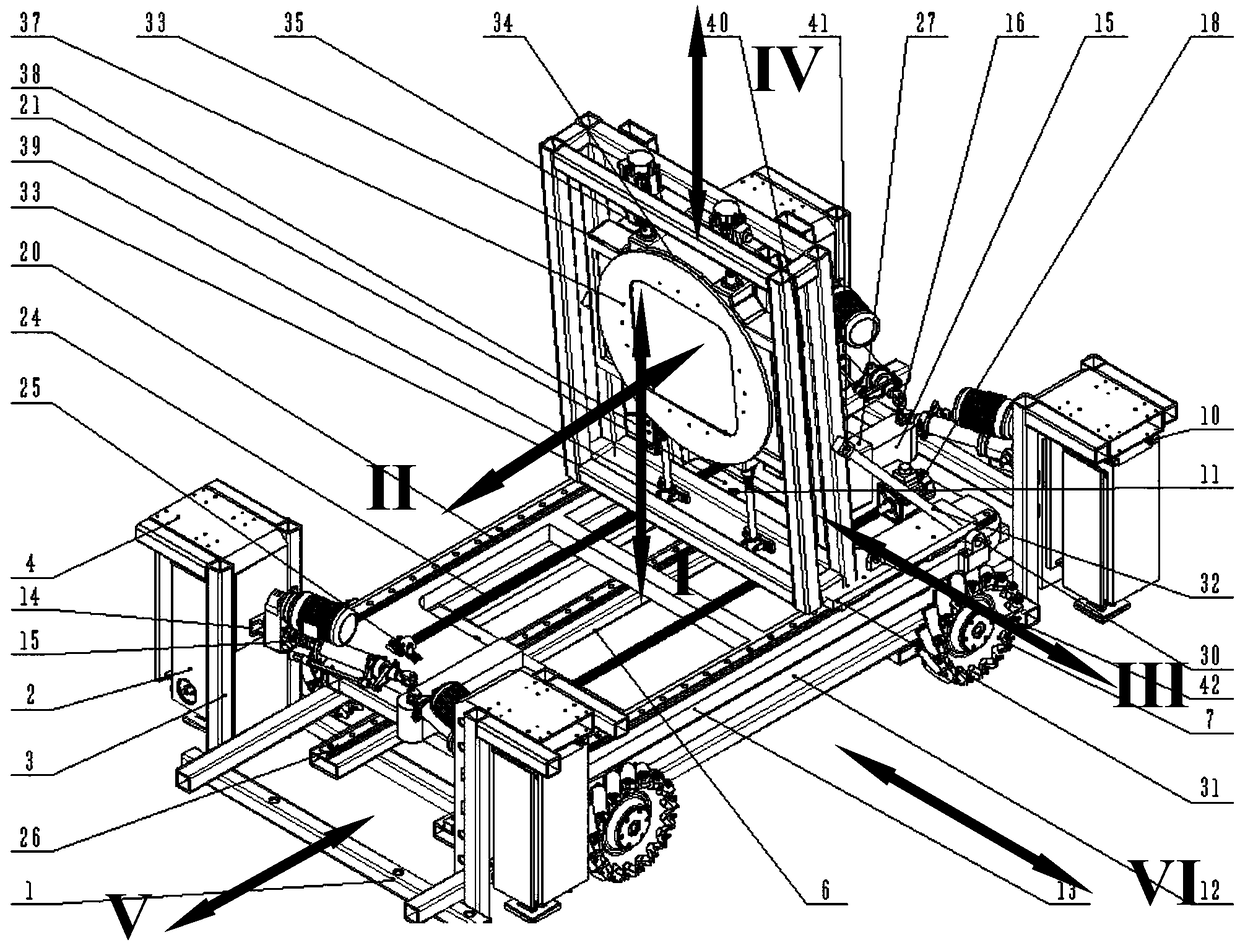

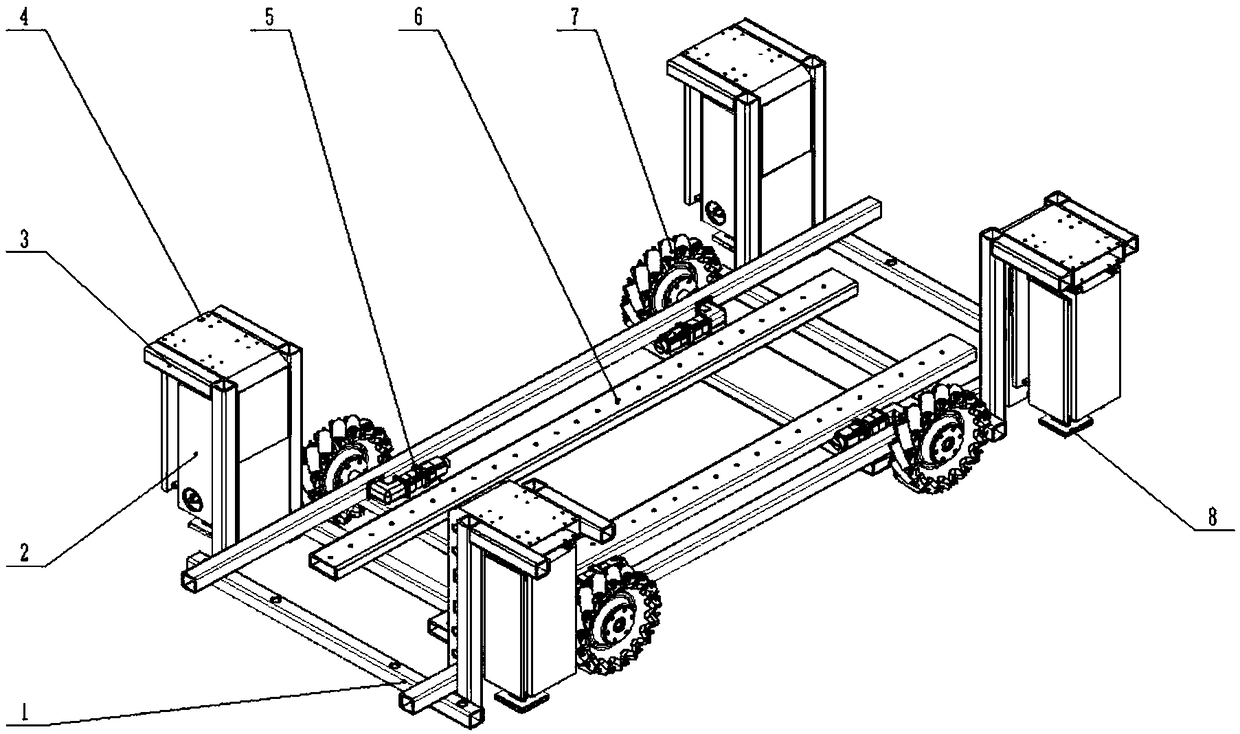

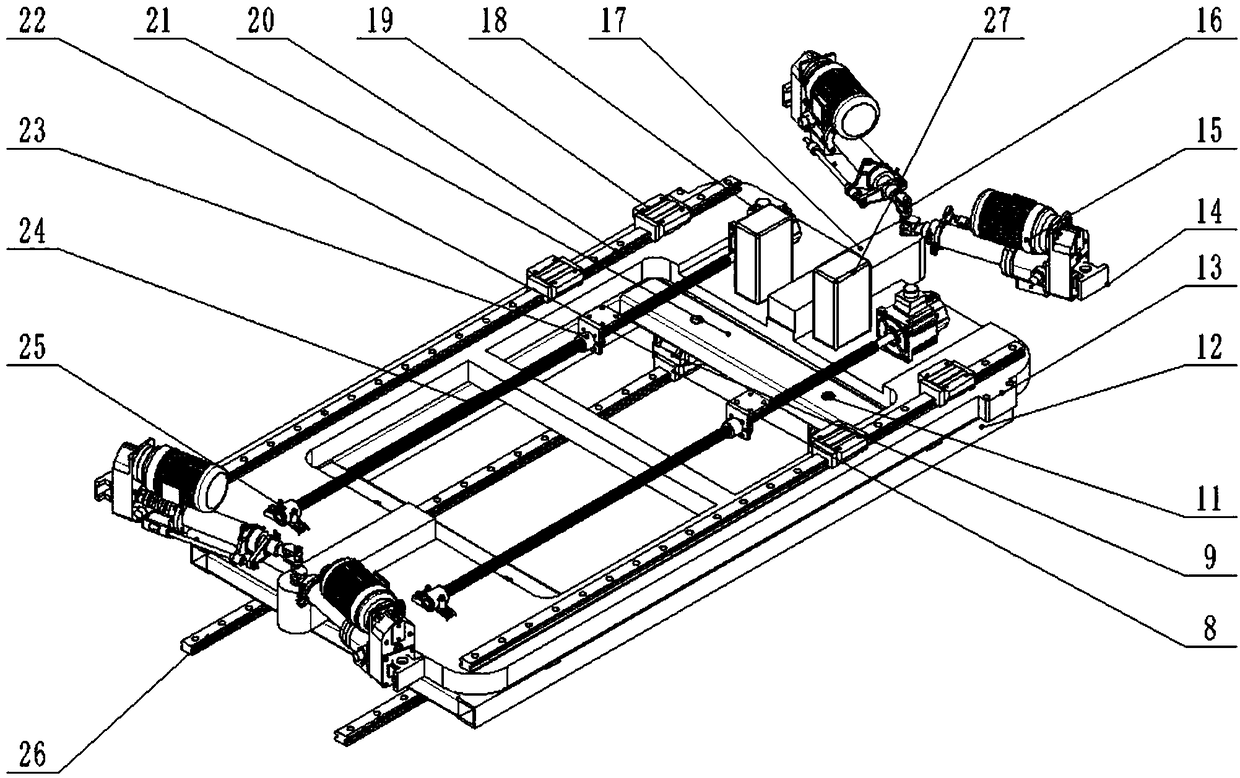

[0019] in figure 1 , figure 2 with image 3 As shown in the schematic diagram of the present invention, the present invention mainly includes three parts: a mobile base, a bottom three-degree-of-freedom motion platform, and a top three-degree-of-freedom motion platform.

[0020] The mobile base consists of a frame 1, a slide mounting frame 6, a wheat wheel drive motor 5, a McKenna mother wheel 7, a leg support frame 3, a leg mounting plate 4, a linear module 2, and a foot plate 8. The frame 1 is a rectangular frame welded by steel profiles, and a set of slide rail mounting frames 6 parallel to each other are fixed on the upper surface of the frame. Four wheat-wheel drive motors 5 are correspondingly provided on the upper part of the frame, and the output shaft of each wheat-wheel drive motor is connected to the corresponding McKenna mother wheel 7. The four corners of the upper part of the frame are respectively fixedly connected to the outrigger support frame 3. The outrigger s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com