Novel accessory derusting equipment and working method thereof

A technology of parts and equipment, which is applied in the field of new parts derusting equipment, can solve the problems of large environmental investment, high price of shot blasting equipment, immovability and other problems, and achieves the effect of low cost, low noise and no dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

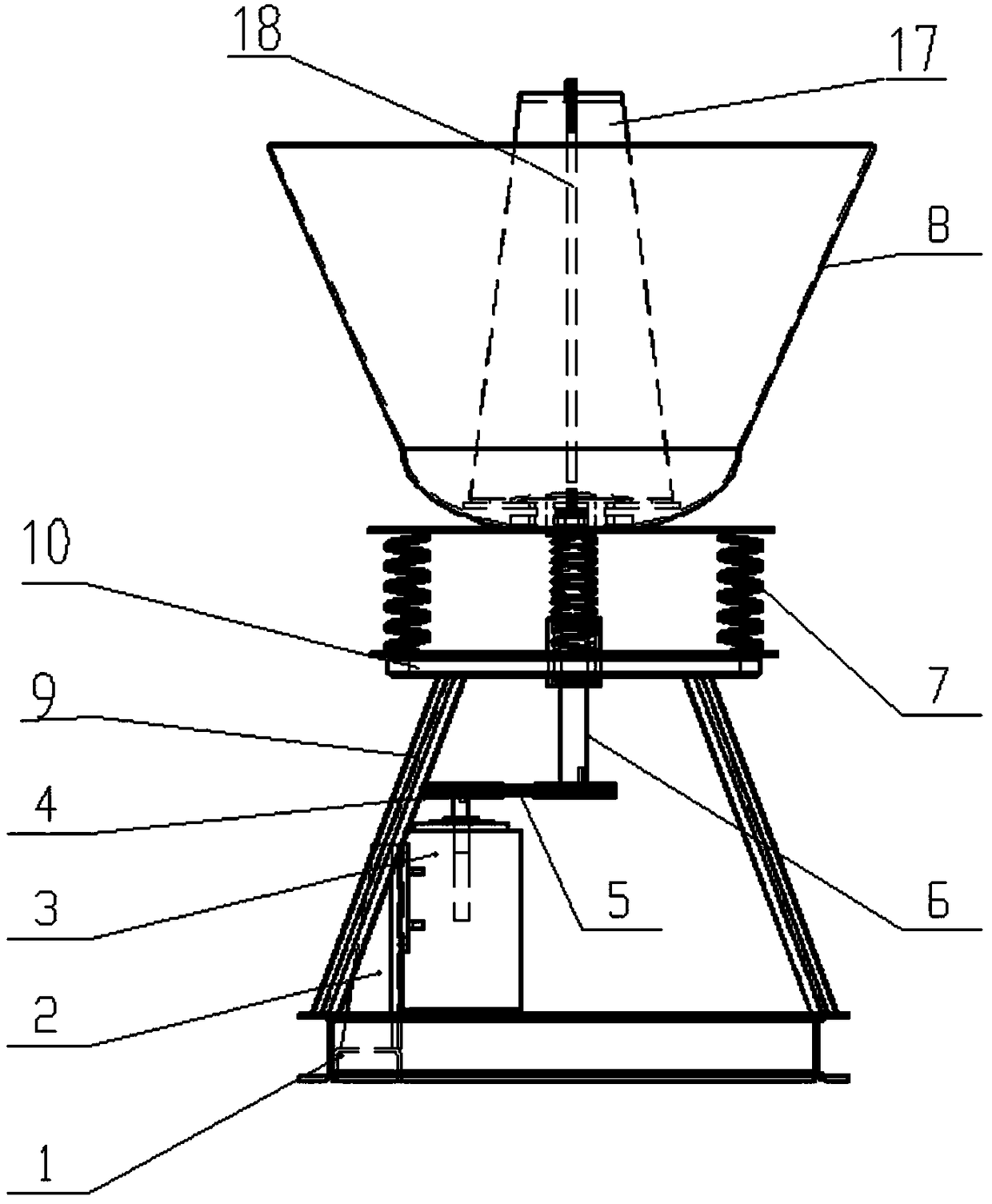

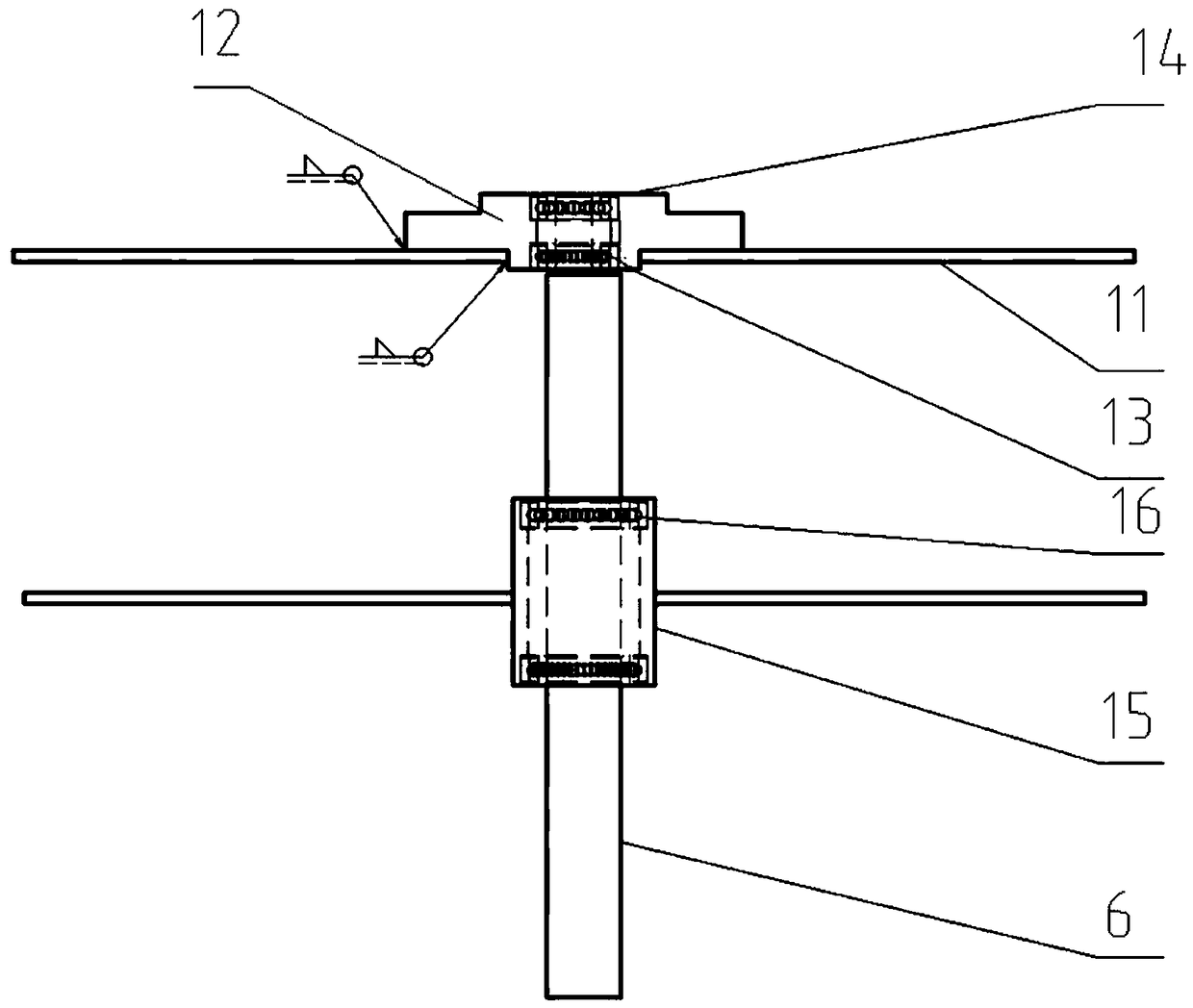

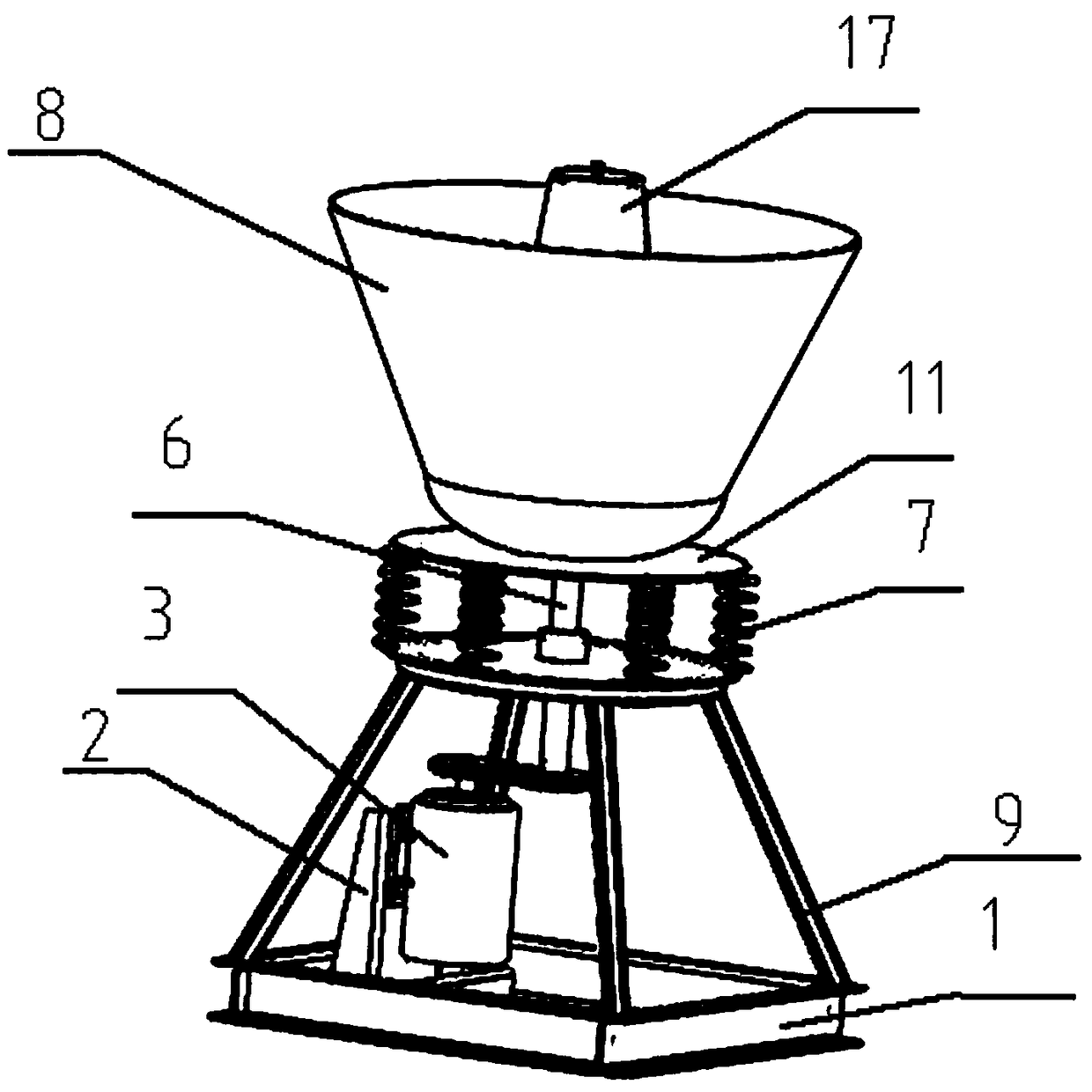

[0020] See attached Figure 1-3 , a new type of parts derusting equipment provided by the present invention is characterized in that, when in use, the equipment base 1 is fixed to the ground with expansion bolts; on the equipment base 1, a bracket 9 is welded and connected, and in the space inside the bracket , a motor 3 is fixed; the motor circuit is connected with a frequency converter, the frequency converter model: PST350-2.2G, rated power 2.2KW, the motor 3 is fixed in the space of the bracket 9 through the motor fixing plate 2, the The motor fixing plate 2 is fixed on the equipment base 1; the output shaft of the motor 3 is connected with a pulley 4, which is connected with the pulley on the eccentric shaft 6 through a belt 5; the eccentric shaft 6 is connected after passing through the fixing plate 10 On the vibrating tray 11, the fixed plate 10 is circular and connected to the eccentric shaft 6. The structure is: a hole is opened in the middle of the fixed plate 10, an...

Embodiment 2

[0022] The working method of the rust removal equipment for the above parts:

[0023] Use the frequency converter to control the motor 3 to drive the eccentric shaft 6 to rotate. The rotation of the eccentric shaft 6 causes vibration, which makes the part container 8 vibrate. At the same time, with the action of the spring 7, put the corroded parts and steel shot and steel sand with different diameters into the part container. , The vibration of the parts container 8 makes the parts fully contact and rub with the steel shot and steel grit, so as to realize the derusting of the parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com