Preparation method of water-cooled spray pipe measuring section structure under large gas flow application conditions

A technology for gas flow and measuring section, which is applied in the field of preparation of the structure of the measuring section of a water-cooled nozzle, can solve problems such as being easily damaged by ablation, and achieve the advantages of optimizing the structure form and material selection, prolonging the service life, and reducing the influence of ablation and erosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] In order to solve the problems of the prior art, the present invention provides a method for preparing the structure of the water-cooled nozzle measuring section under the condition of using a large gas flow rate. The preparation method includes:

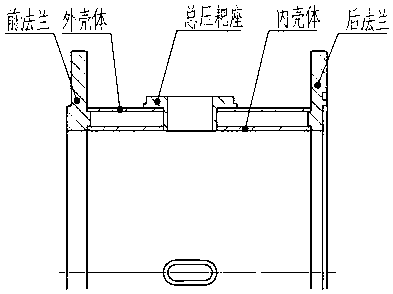

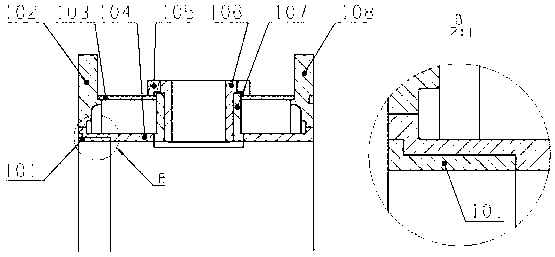

[0024] Step 1: Prepare and set the front flange 102, the outer casing 103, the inner casing 104 and the rear flange 108 for forming the structure of the water-cooled nozzle measurement section according to the application conditions of the water-cooled nozzle;

[0025] Step 2: prepare a connecting seat 105 with ears extending inwardly on the upper part, as a connecting part between the total pressure rake mounting seat and the outer shell 103, and weld the connecting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com