Large diamond saw blade top edge sharpening workbench rotary mechanism

A diamond saw blade and rotating mechanism technology, applied in metal sawing equipment, metal processing equipment, manufacturing tools and other directions, can solve the problems of large vibration, accelerated edge wear, roundness error, etc., to achieve high production efficiency, cutting edge The effect of good quality and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

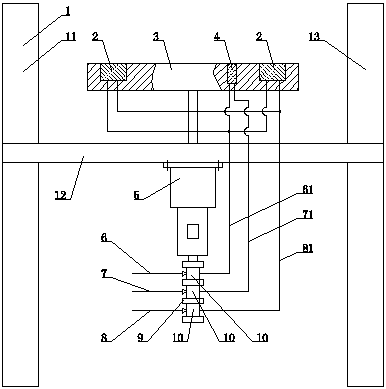

[0007] see figure 1 , the present invention includes a frame 1, a tray 3, a proximity sensor 4, a motor 5, a public power input line 6, a proximity sensor control signal input line 7, an electromagnetic chuck power switch signal input line 8, and a public power output line 61 , proximity sensor control signal output line 71, electromagnetic chuck energization switch signal output line 81, slip ring insulation sleeve 9, three slip rings 10 and several electromagnetic chucks 2, the left side plate 11, Carrying plate 12 and right side plate 13, described motor 5 adopts screw to be loaded on the carrying plate 12, and described support tray 3 is contained in the upper end of the output shaft of motor 5, and described proximity sensor 4 and several electromagnetic chucks 2 Installed in the hole of the tray 3, the slip ring insulation sleeve 9 is mounted on the bottom of the output shaft of the motor 5, and the three slip rings 10 are installed on the slip ring insulation sleeve 9 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com