Preparation method of silicone oil repair graphene reinforced aluminum base composite material

A composite material and reinforced aluminum-based technology, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of difficulty in uniform dispersion of graphene and increased content of graphene defects, and achieve low volatility, convenient follow-up operation, and thick diameter greater effect than

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

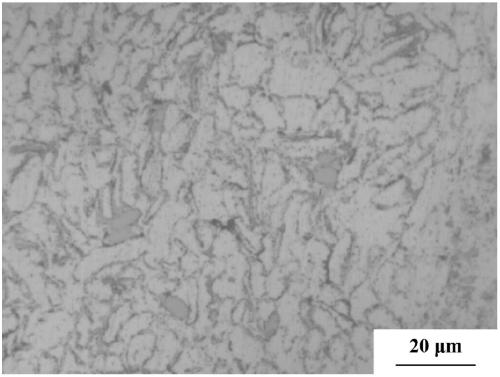

[0033] Specific embodiment one: the preparation method of silicone oil repairing graphene reinforced aluminum matrix composite material in this embodiment is carried out according to the following steps: 1. Weighing

[0034] Take by weighing 0.5%~4% graphene, 0.5%~10% silicone oil and the aluminum metal powder of surplus as raw material by mass fraction; Described graphene is few-layer graphene, and average sheet diameter is 200nm~25 μ m, and average thickness is 1~30nm;

[0035] The aluminum metal powder is aluminum alloy;

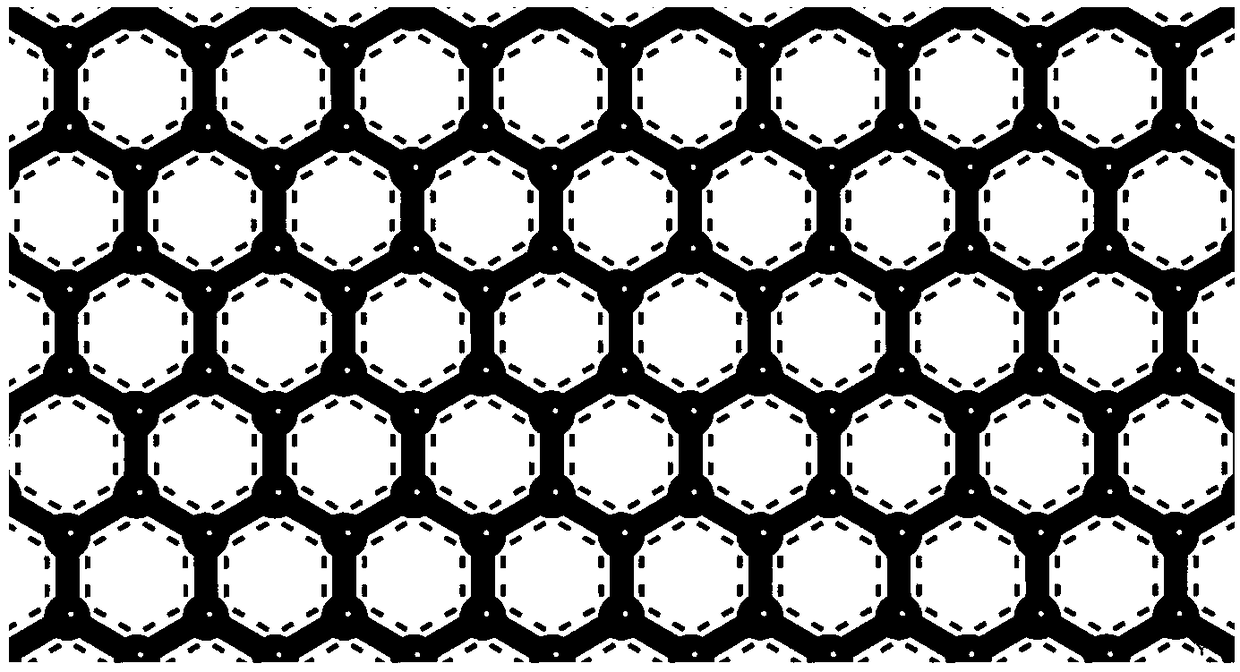

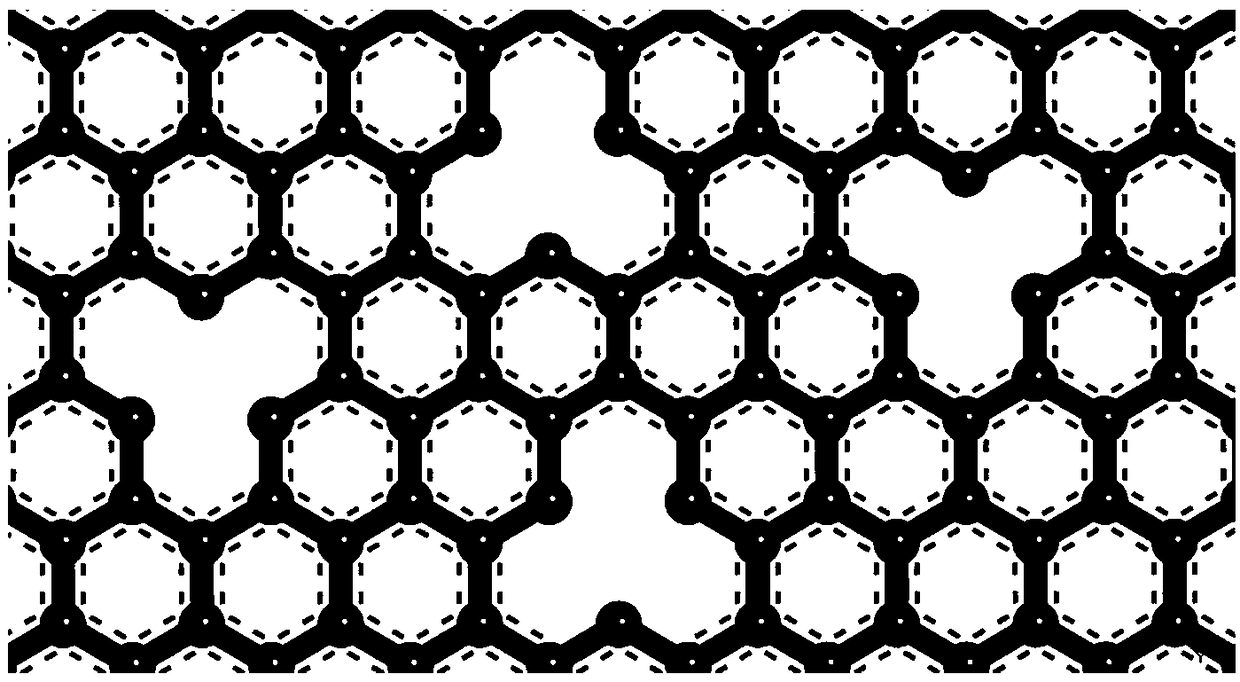

[0036] 2. Graphene dispersion and prefabricated block forming

[0037] Put the graphene, silicone oil and aluminum metal powder weighed in step 1 into a ball milling tank, ball mill the obtained mixed powder at a speed of 150-400 rpm for 0.5-4 hours, and put the mixed powder obtained after ball milling into a cold-pressing mold for cold Press to obtain silicone oil-graphene / aluminum prefabricated body;

[0038] 3. Prefabricated body insulation

[0039] ...

specific Embodiment approach 2

[0050] Embodiment 2: This embodiment is different from Embodiment 1 in that: the average particle size of the aluminum metal powder in Step 1 is 1-30 μm. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0051] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the silicone oil in Step 1 is polydimethylsilicone oil or polyphenyl silicone oil. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com