Novel prepreg presoaking device

A prepreg and prepreg technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of uneven glue, uneven glue penetration, and irreparable problems, and achieve the effect of uniform squeegee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

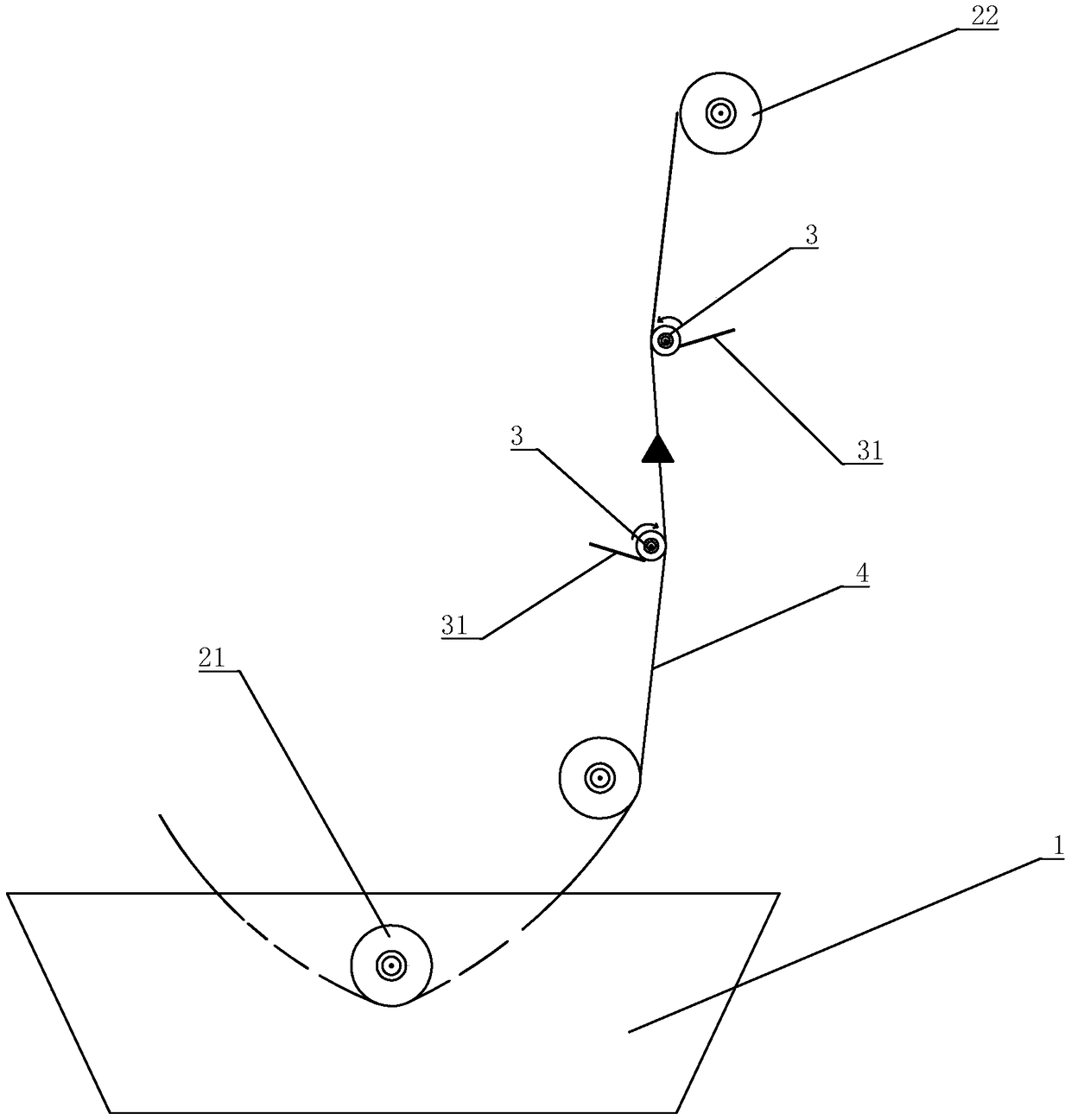

[0013] refer to figure 1 , a new type of prepreg prepreg device of the present invention, including a glue tank 1 and a conveying roller, the conveying roller includes a prepreg roller 21 arranged in the glue groove 1 and a first transmission roller 22 arranged above the glue groove 1, At least two squeegee rollers 3 are arranged between the first transmission roller 22 and the prepreg roller 21, and the squeegee rollers 3 are respectively arranged on both sides of the transmission direction to scrape glue on the front and back sides; A scraper 31 is provided, and a driving device is connected to the squeegee roller 3 to drive the squeegee roller 3 to actively rotate, and at the same time, the rotation direction of the squeegee roller 3 is opposite to the transmission direction. In this device, the glass fiber cloth 4 is made of The conveying roller conveys, the prepreg roller 21 guides the glass fiber cloth 4 into the glue tank 1 for dipping, and the glass fiber cloth 4 passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com