Bipolar pre-charging device with single power supply transverse rod

A pre-charged, single power supply technology, applied in the field of dust removal, can solve the problem of difficult charging of dust, and achieve the effect of simple production, favorable electrostatic coagulation, and large dust collection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

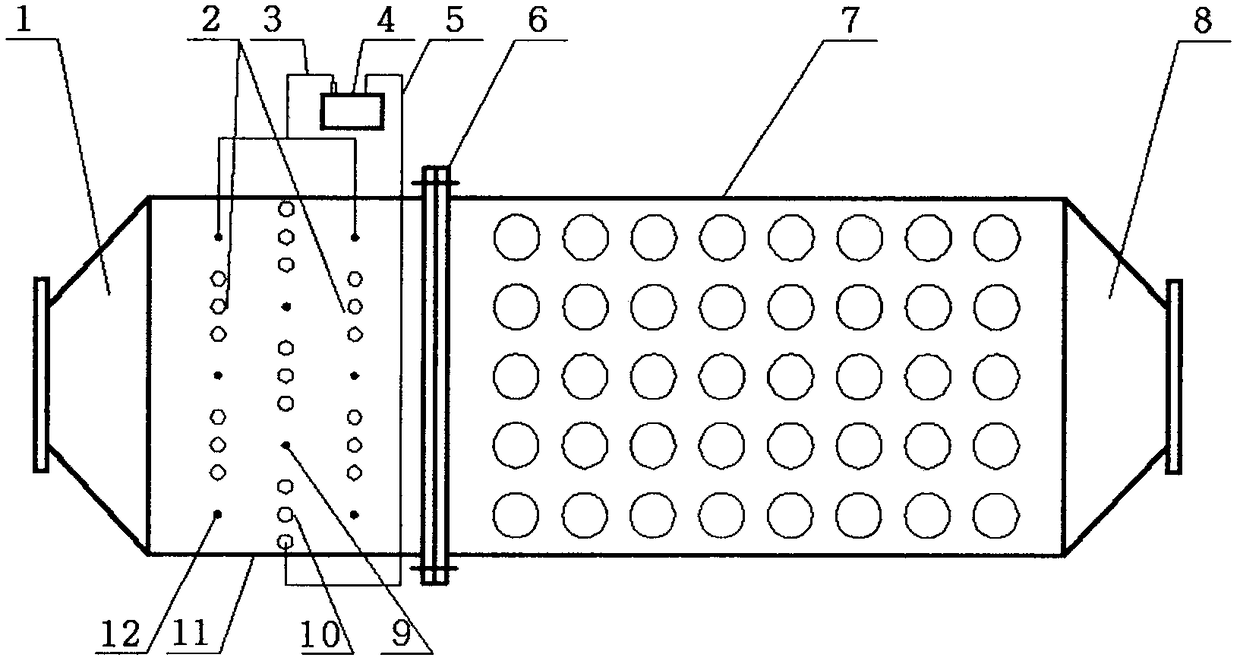

[0032] An electrostatically enhanced fiber filter and dust removal equipment composed of a horizontal rod curtain bipolar pre-charged device and a bag filter, such as figure 1 shown. The dust removal equipment is composed of an air intake box 1, a preload electrical appliance 11, a high-voltage cable 3, a high-voltage DC power supply 4, a grounding cable 5, a bag filter 7, and an air outlet box 8. The air intake box 1 is fixedly connected to the inlet end of the preloader 11, the outlet end of the preloader 11 and the inlet end of the bag filter 7 are fixedly connected by a flange 6, and the outlet end of the bag filter 7 is connected to the outlet box 8 Fixed link.

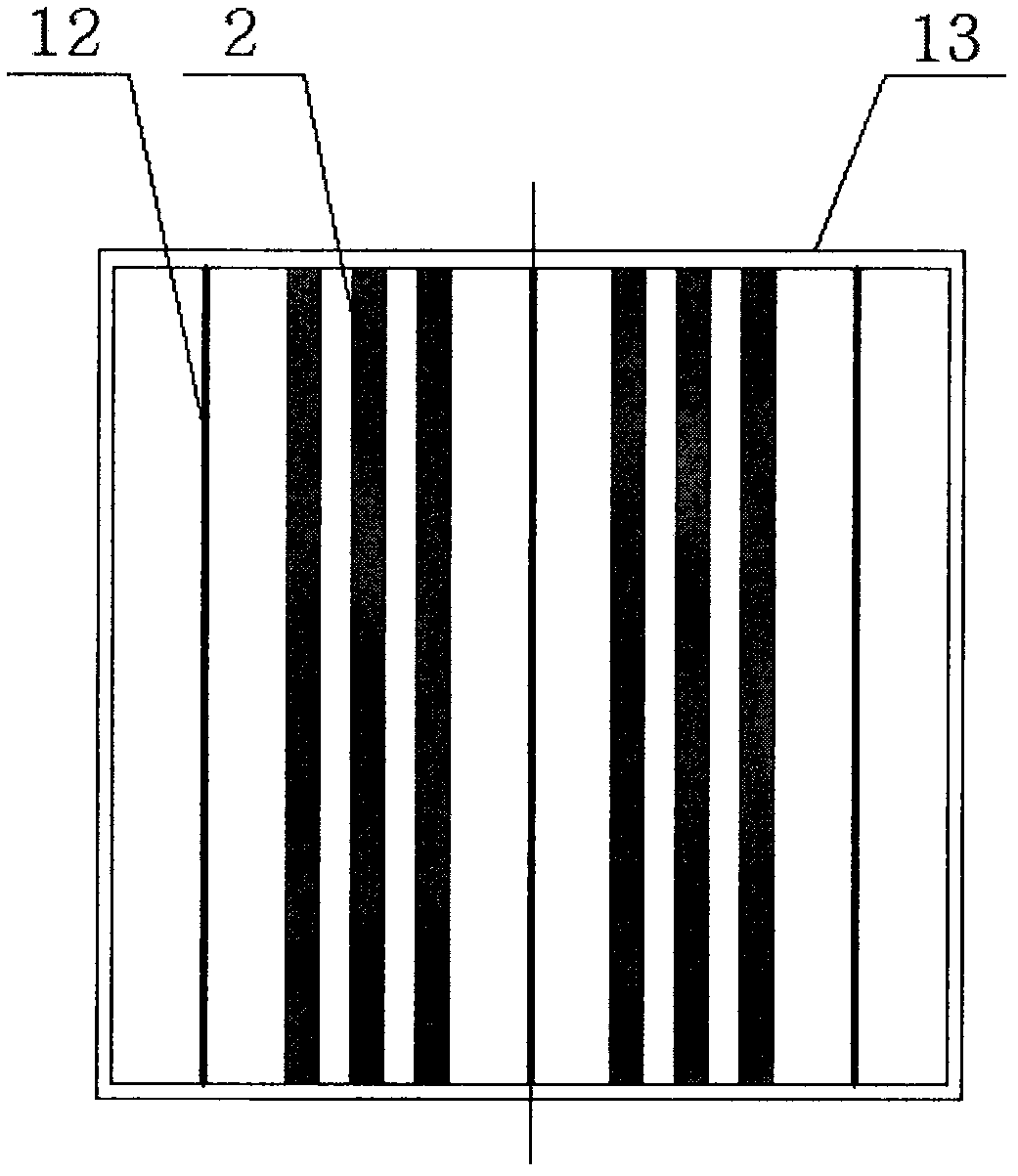

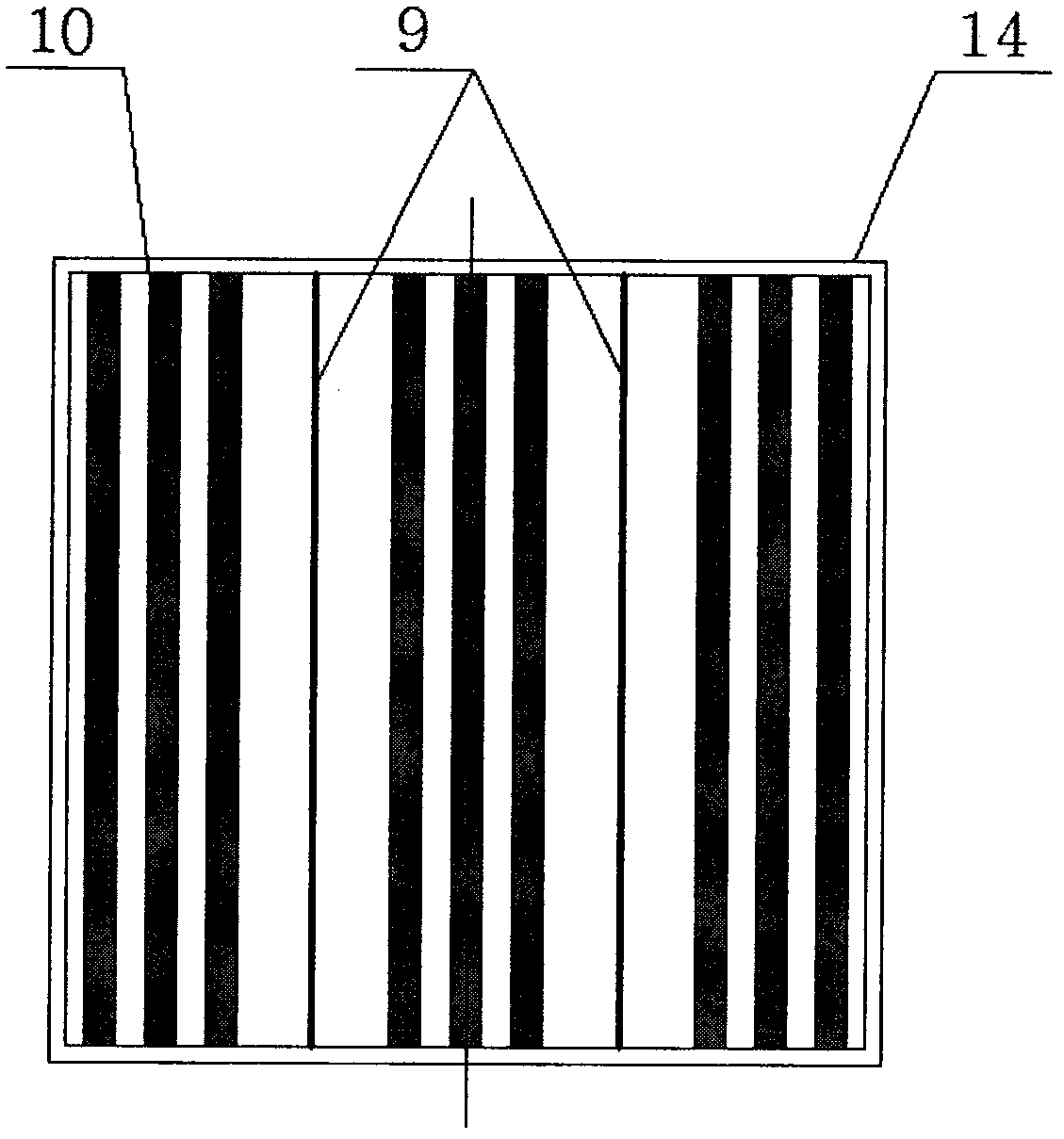

[0033] The structure of the preloader 11 is as Figure 1~3 As shown: the cathode tube groups 2 and the cathode corona wires 12 are alternately fixed on the cathode rod curtain frame 13, and the anode tube groups 10 and the anode corona wires 9 are alternately fixed on the anode rod curtain frame 14. The cathod...

Embodiment 2

[0042] An electrostatic coagulation and dust removal equipment composed of a horizontal rod curtain bipolar pre-charging device and an electrostatic precipitator, such as Figure 4 Shown, except following structure, all the other are with embodiment 1.

[0043] In the composition of the electrostatic condensation and dust removal equipment, the outlet end of the pre-charger 11 is fixedly connected to the inlet end of the electrostatic precipitator 15 through the flange 6, and the outlet end of the electrostatic precipitator 15 is fixedly connected to the gas outlet box 8.

[0044] Such as Figure 5 As shown, in each cathode rod curtain frame 13, cathode corona wires 12 and cathode tube groups 2 are alternately and evenly arranged. Cathode tube group 2 is composed of four circular tubes with a diameter of 20 mm arranged equidistantly, and the distance between the circular tubes is equal to the diameter of the circular tubes. The width of the cathode tube group 2 is 140 mm, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com