Mixer for shower gel production

A blender and shower gel technology, which is applied in the field of shower gel production equipment, can solve problems such as roughness, difficulty in mixing oil and water in shower gel materials, and no defoaming function, so as to improve efficiency, improve production quality, and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

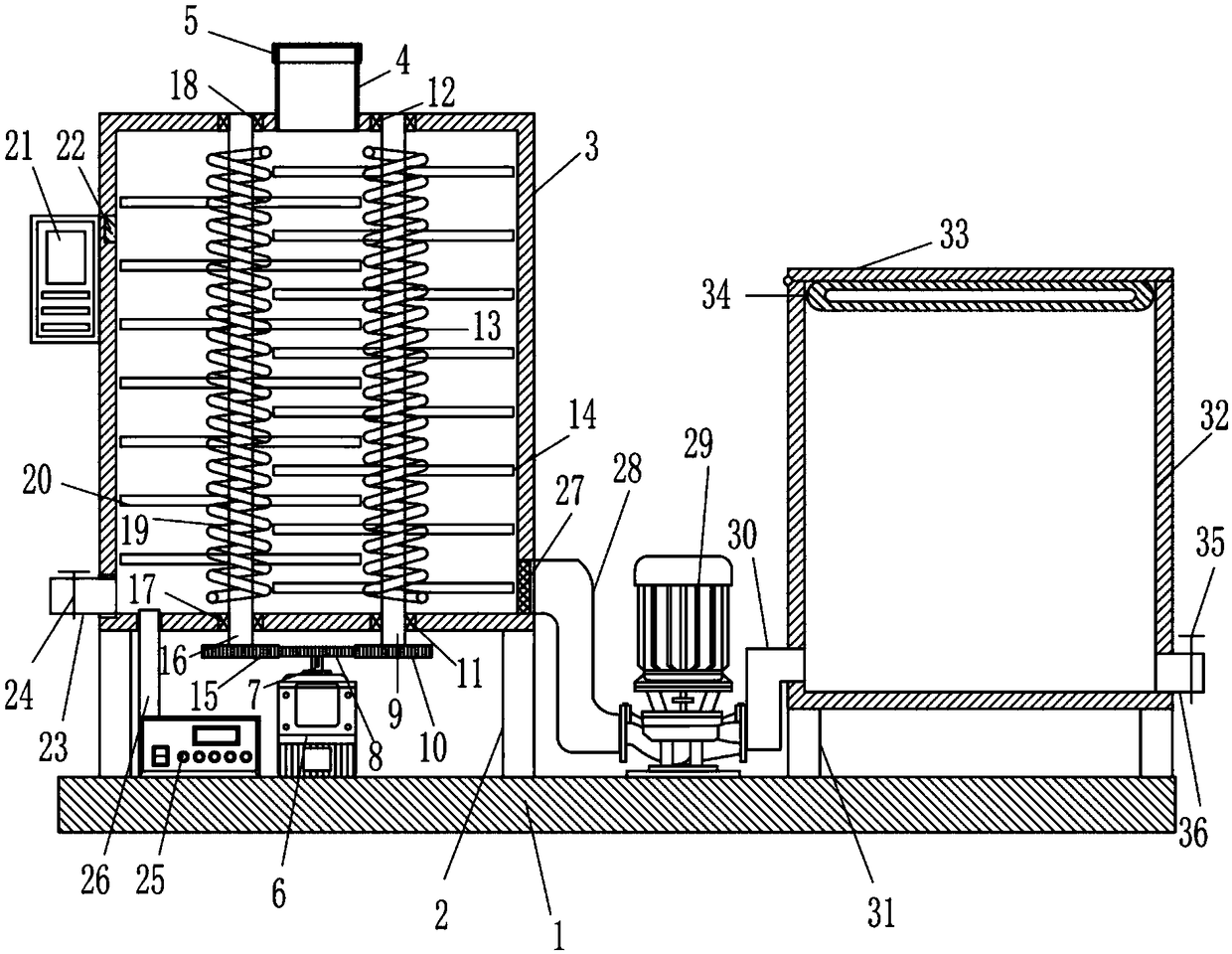

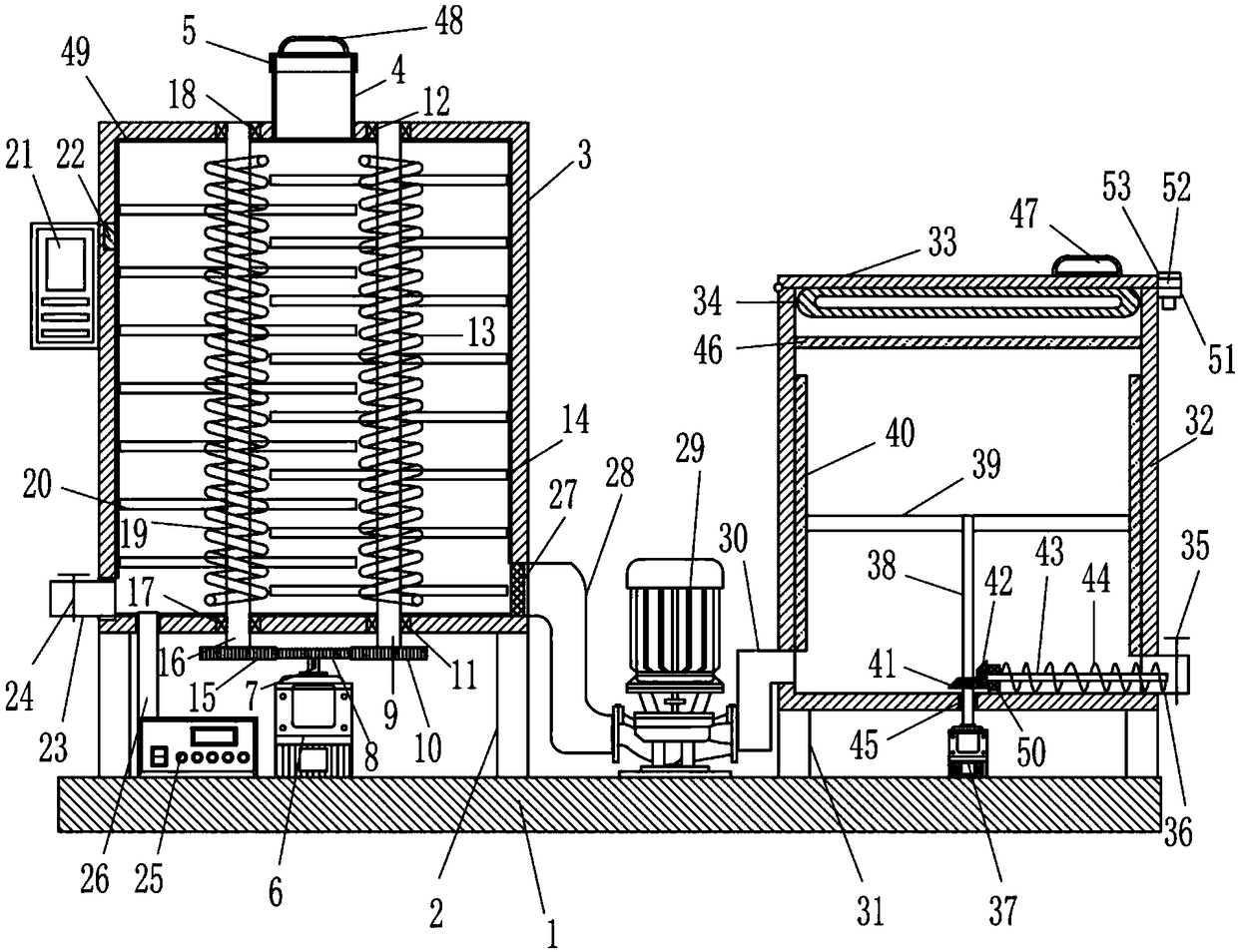

[0027] A mixer for the production of body wash, such as Figure 1-2As shown, it includes a base 1, a first bracket 2, a mixing tank 3, a feed pipe 4, a cover 5, a first motor 6, a first shaft 7, a first gear 8, a second shaft 9, a second gear 10, The first bearing seat 11, the second bearing seat 12, the first heating wire 13, the first stirring rod 14, the third gear 15, the third rotating shaft 16, the third bearing seat 17, the fourth bearing seat 18, the second heating wire 19. Second stirring rod 20, temperature sensor 21, sensing element 22, sewage pipe 23, first valve 24, ultrasonic generator 25, ultrasonic energy conversion pipe 26, liquid pumping pipe 28, liquid pump 29, liquid outlet pipe 30 , the second bracket 31, the sterilization tank 32, the cover plate 33, the ultraviolet lamp 34, the second valve 35 and the drain pipe 36; Connected to the top of the base 1, the first bearing seat 11 and the third bearing seat 17 are embedded in the bottom of the stirring tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com