Slow wave structure suitable for dual-sheet backward wave oscillator

A technology of slow wave structure and wave oscillation, applied in the field of slow wave structure, can solve the complex processing and complex problems of slow wave structure, and achieve the effect of simple structure, high power output and interaction efficiency, and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

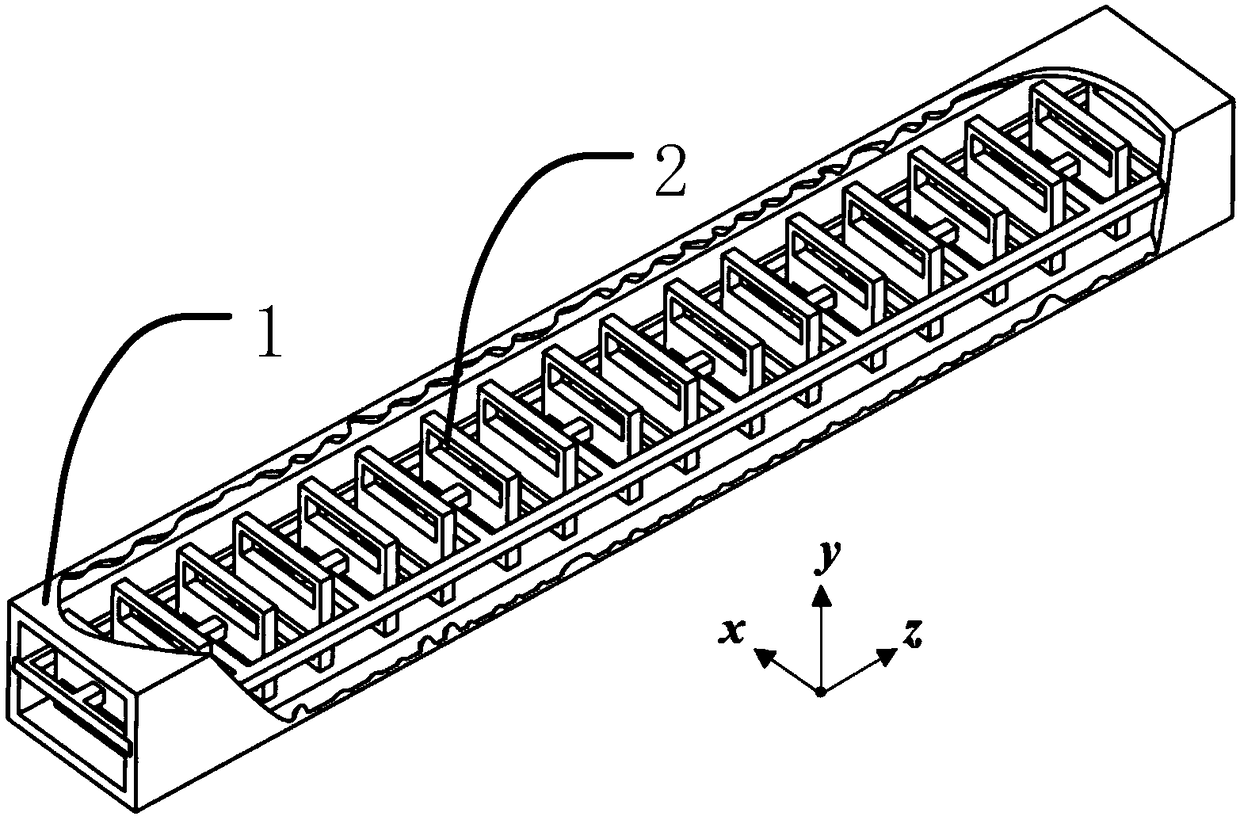

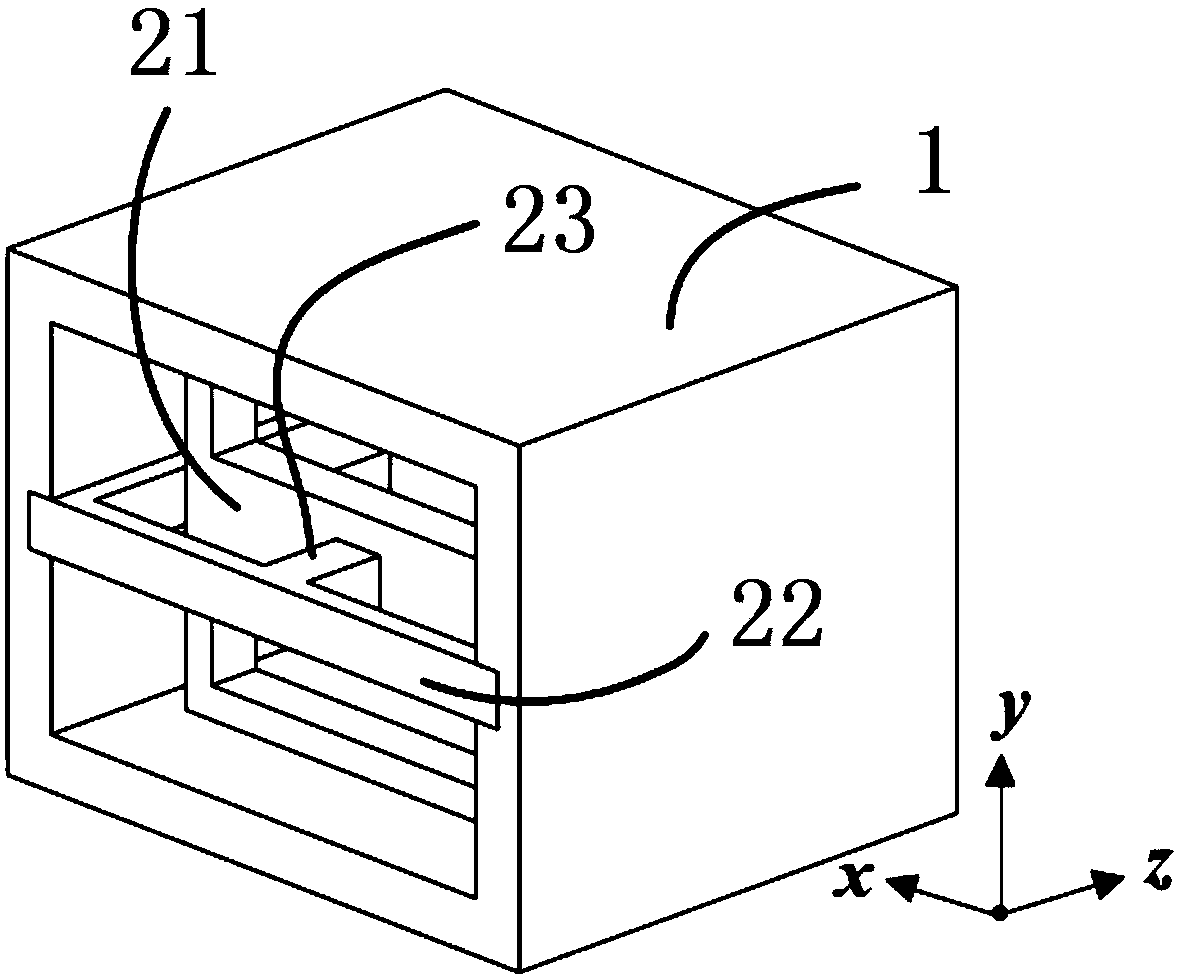

[0027] figure 1 It is a structural diagram of a specific embodiment of the present invention applicable to the slow-wave structure of the dual-ribbon injection back-wave oscillator. In order to better demonstrate the internal structure of the present invention, figure 1 Part of the rectangular waveguide is hidden in . Such as figure 1 As shown, the slow-wave structure applicable to the double-ribbon injector return wave oscillator of the present invention includes a rectangular waveguide 1 and several vertical metal plate pair structures 2, and the present invention is a periodic structure. figure 2 It is a single-period structure diagram of the slow-wave structure applicable to the double-band injection back-wave oscillator of the present invention.

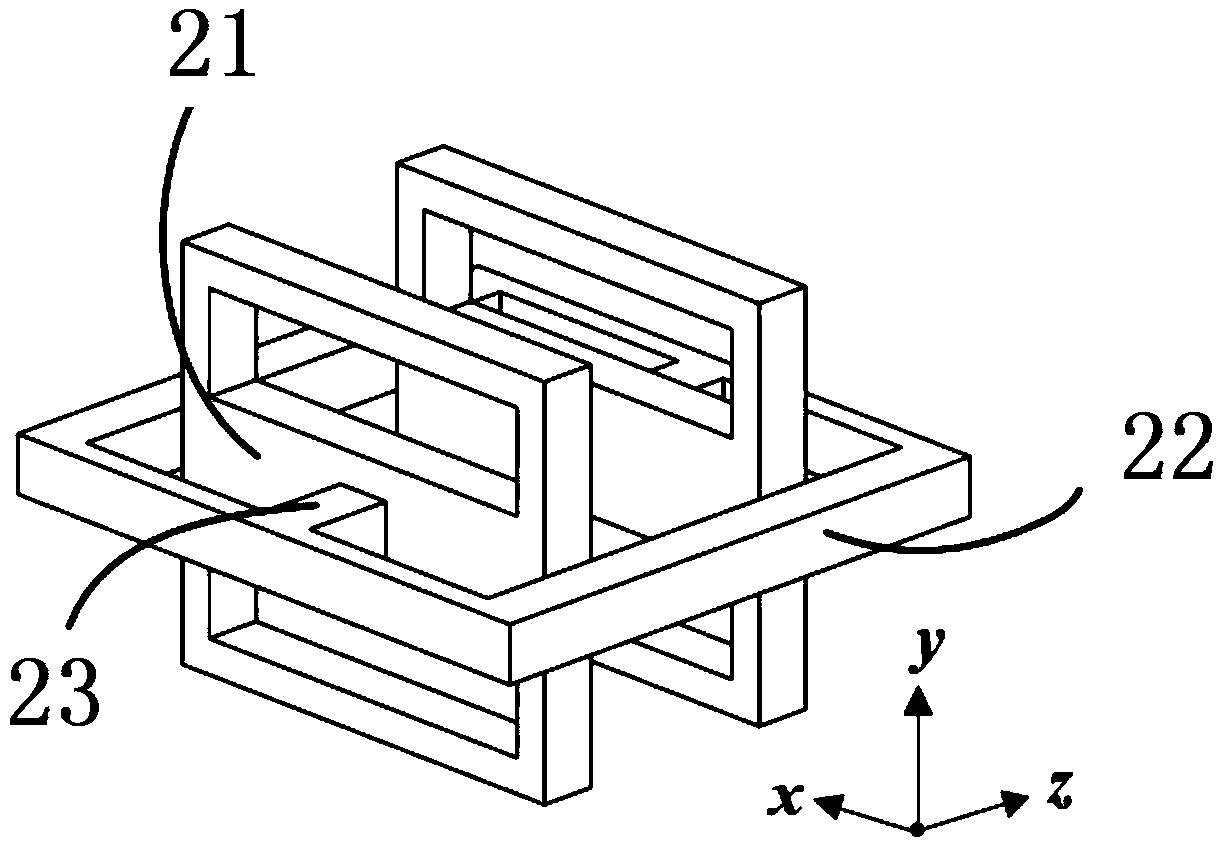

[0028] The rectangular waveguide 1 is a commonly used technology in the microwave field, and is not the technical focus of the present invention, so it will not be described in detail here. Next, the structure 2 of the verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com