High-efficiency high-quality snap-action temperature controller

A sudden jump thermostat, high-quality technology, applied in the direction of thermal switch parts, etc., can solve the problems of lower product qualification rate, riveting, and shortened working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail by the following examples.

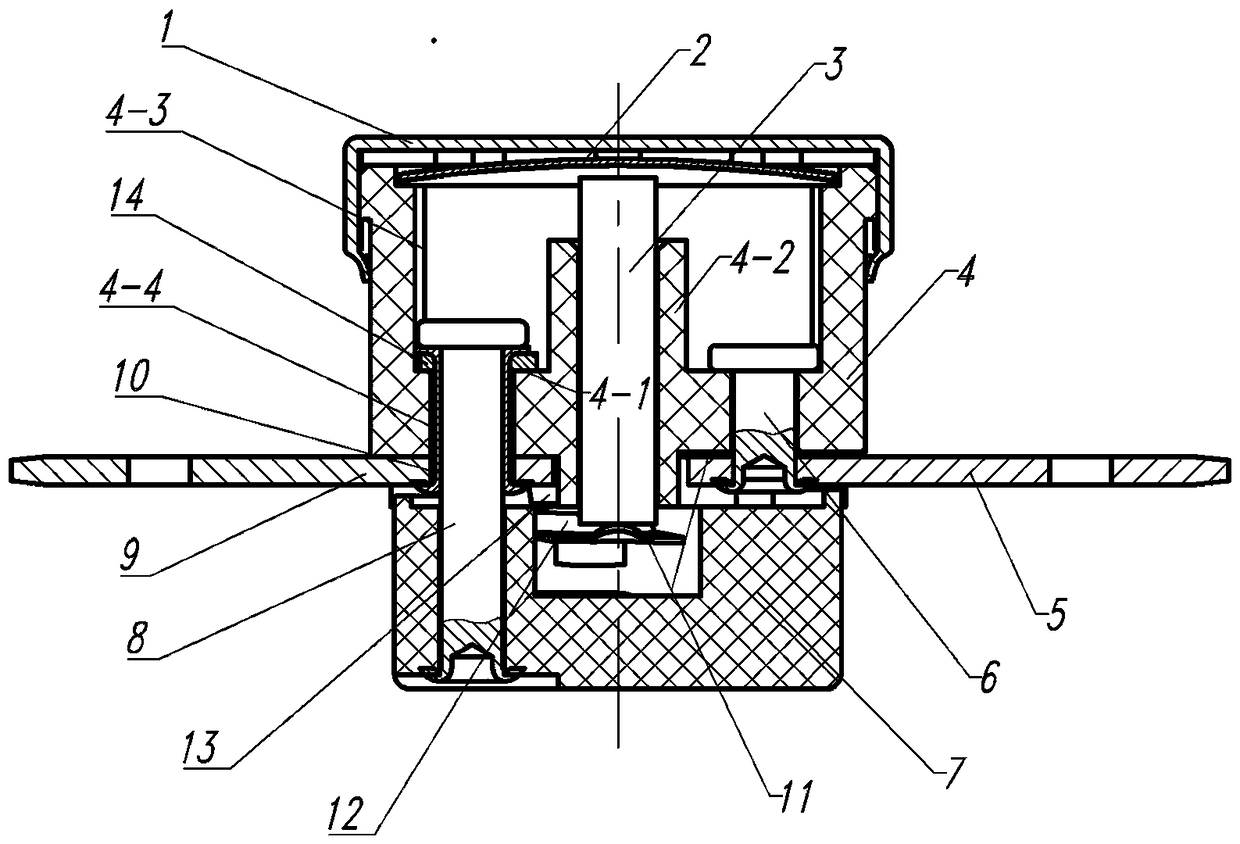

[0015] see Figure 2-4 As shown, a high-efficiency and high-quality jump-type thermostat includes a cover 1, a bimetal disc 2, an action rod 3, a casing 4, a third terminal 5, a third rivet 6, a cover plate 7, and a third rivet. 4. Rivet 8, fourth terminal 9, movable contact bracket 11, movable contact 12 and fixed contact 13, bimetallic disc 2 is placed in the horizontal inner groove on the top of housing 4, and actuating rod 3 is placed vertically The movement runs through the central through hole of the central cylindrical boss 4-2 of the housing 4, the moving contact 12 is fixedly installed at one end of the moving contact bracket 11, and the other end of the moving contact bracket 11 passes through the third terminal 5 and the third rivet 6 are riveted with the housing 4, the fixed contact 13 is fixed on the inner end of the fourth terminal 9 and is opposite to the moving contact 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com