Oil well separation equipment

A technology for separating equipment and oil wells, applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problems of easy blockage, thick filter layer, short life, etc., achieve fast mud sand removal, high sand control efficiency, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with the accompanying drawings.

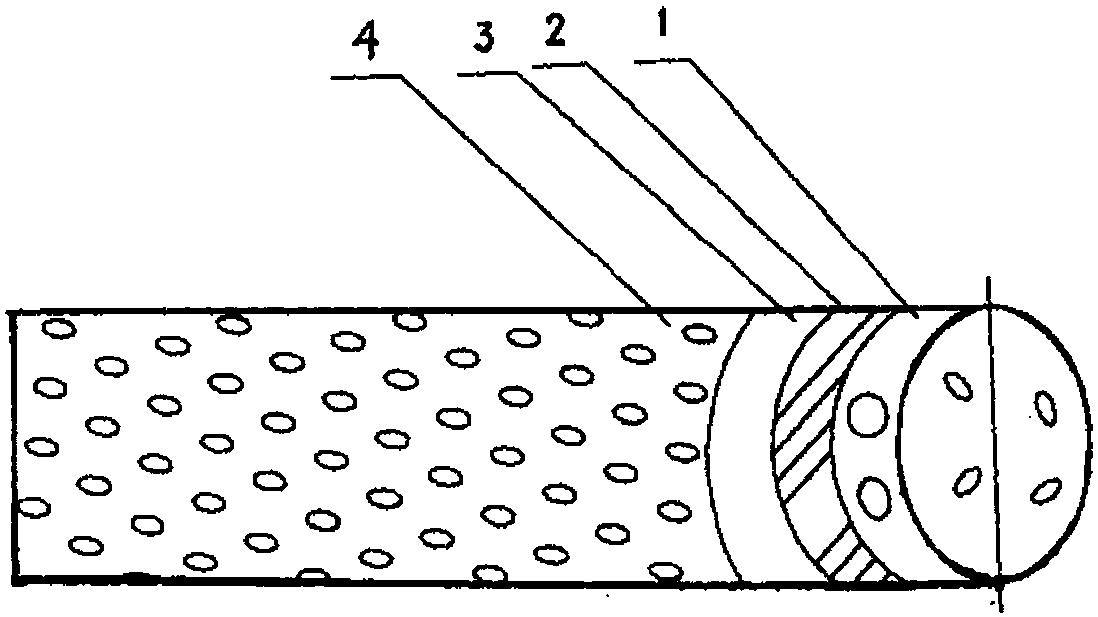

[0008] see figure 1 , the present invention is composed of: porous inner tube 1, inner support frame 2, expanded stainless steel mesh 3 and outer protective tube 4, the outer layer of oil well separation equipment is outer protective tube 4, the inner layer is porous inner tube 1, outer protective tube 4 It is a porous metal tube, and there is an interlayer between the outer protection tube 4 and the porous inner tube 1. The interlayer is built with stainless steel expanded mesh 3 and inner support frame 2, and the cylinder wall of the stainless steel expanded mesh 3 is evenly covered with rectangular pores. After computerized hole drainage, it is corroded by synthetic acid, which has good pressure resistance, fast mud and sand removal, small oil flow resistance, and large liquid extraction volume. The supporting frame 2 is a metal bracket for supporting the expanded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com