Novel bulk emulsion explosive and preparation method thereof

An emulsion explosive, a new type of technology, is used in explosive processing equipment, explosives, explosive compound components, etc., to achieve the effects of excellent safety, simple charging method, and reduced harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

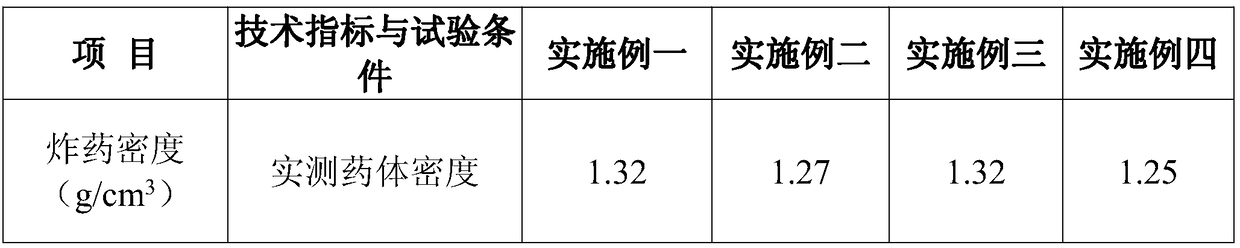

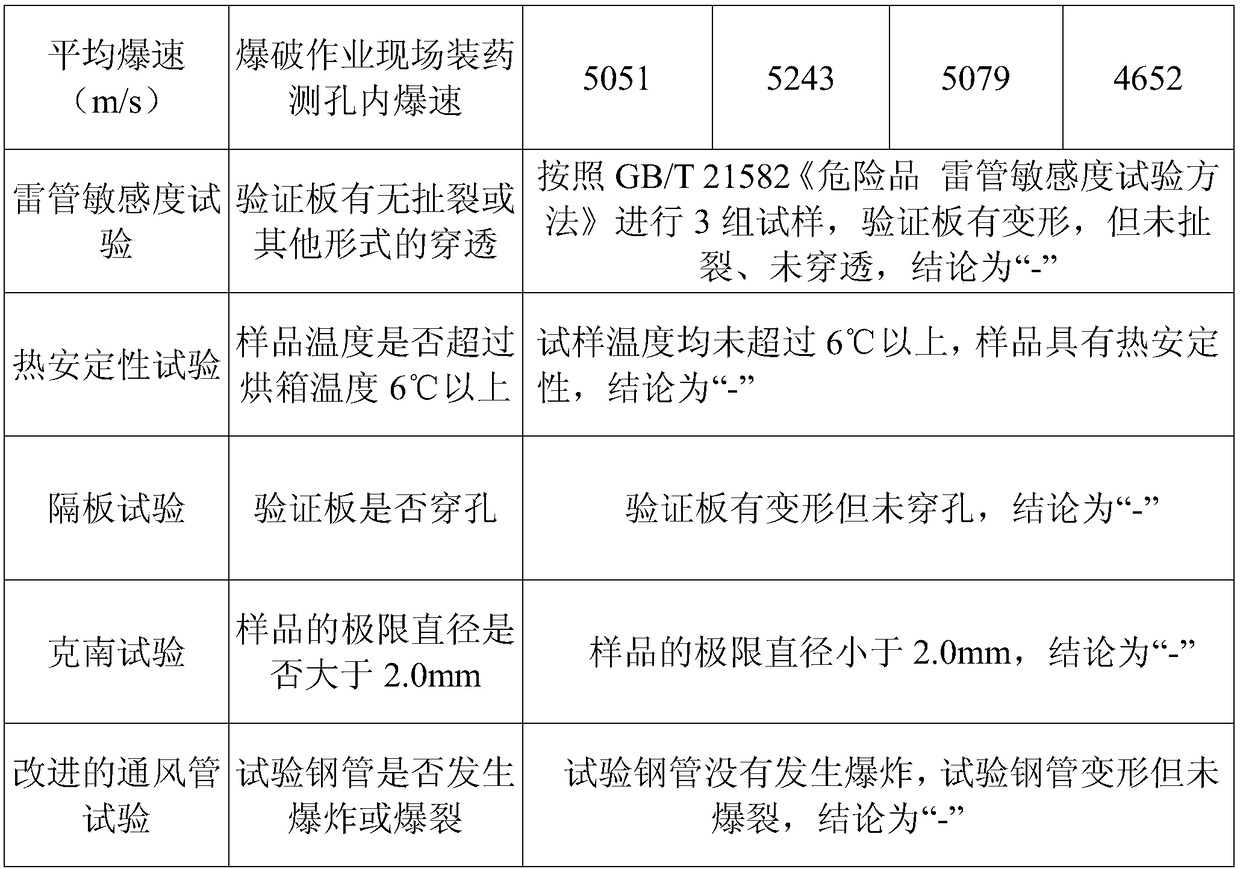

Examples

Embodiment 1

[0035] A new type of bulk emulsion explosive, produced by the factory's emulsion explosive production line, is packed in large bags, and is composed of latex matrix and sensitizing materials. The latex matrix is composed of the following components in mass percentages: ammonium nitrate 68%, sodium nitrate 9.8%, 16% water, 3.5% diesel oil, 1.5% engine oil, 1.2% polyisobutylene succinic anhydride emulsifier; the sensitization material is hollow glass microspheres, with an average particle size of 0.1mm and a density of 0.35g / cm 3 , the amount of hollow glass microspheres is 0.3% of the mass of the latex matrix.

[0036] The preparation method of above-mentioned novel bulk emulsion explosive is:

[0037] (1) Water phase preparation: mix water, ammonium nitrate and sodium nitrate according to the above ratio, heat and dissolve, stir evenly, and keep the temperature at 85°C to obtain an aqueous phase solution;

[0038] (2) Oil phase preparation: Stir and mix the combustible agen...

Embodiment 2

[0043] A new type of bulk emulsion explosive, produced by the factory's emulsion explosive production line and transported by a charging vehicle, is composed of latex matrix and sensitized material. The latex matrix is composed of the following components in mass percentages: 77% of ammonium nitrate, 15.5% of water, white 5% oil, 2.5% polyisobutylene succinic anhydride emulsifier; the sensitized material is plastic microspheres, the average particle size is 0.02mm, and the density is 0.03g / cm 3 , the amount of plastic microspheres is 0.1% of the mass of the latex matrix.

[0044] The preparation method of above-mentioned novel bulk emulsion explosive is:

[0045] (1) Water phase preparation: mix water and ammonium nitrate according to the above ratio, heat and dissolve, stir evenly, and keep the temperature at 80°C to obtain an aqueous phase solution;

[0046] (2) Oil phase preparation: Stir and mix the combustible agent and emulsifier according to the above ratio, and keep...

Embodiment 3

[0051] A new type of bulk emulsion explosive, produced by the on-site mixed emulsion explosive ground preparation station, packed in large bags, composed of latex matrix and sensitized material, the latex matrix is composed of components in mass percentage: ammonium nitrate 68%, nitric acid 12% sodium, 15% water, 3% white oil, 2% polyisobutylene succinic anhydride emulsifier; the sensitization material is hollow glass microspheres, the average particle size is 0.02mm, and the density is 0.1g / cm 3 , the amount of hollow glass microspheres is 1.2% of the mass of the latex matrix.

[0052] The preparation method of above-mentioned novel bulk emulsion explosive is:

[0053] (1) Water phase preparation: mix water, ammonium nitrate and sodium nitrate according to the above ratio, heat and dissolve, stir evenly, and keep the temperature at 85°C to obtain an aqueous phase solution;

[0054] (2) Oil phase preparation: Stir and mix the combustible agent and emulsifier according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com