Adaptive heat dissipation device of vehicle-mounted equipment

A heat dissipation device and vehicle-mounted equipment technology, applied in the electrical field, can solve the problems of increasing the noise of the heat dissipation system, potential safety hazards, and failure to meet the requirements of low power consumption, etc., and achieve the effects of reducing heat dissipation power consumption, high reliability, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

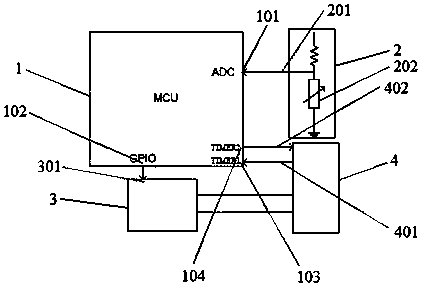

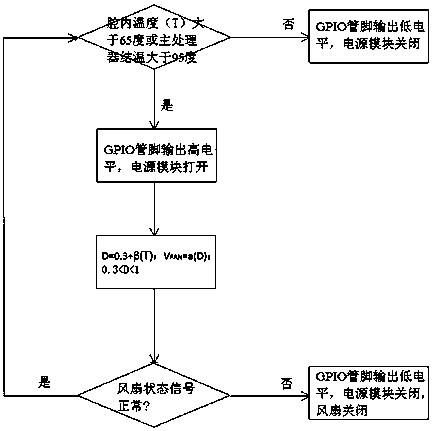

[0012] Such as Figure 1 to Figure 2 As shown, the vehicle-mounted equipment adaptive heat dissipation device of the present invention includes an MCU microcontroller 1, a temperature detection module 2, a power supply module 3 and a fan 4, and the temperature signal output terminal 201 of the temperature detection module 2 and the ADC of the MCU microcontroller 1 The pin 101 is connected, the temperature detection module 2 monitors the temperature in the cavity of the vehicle equipment and converts it into a voltage signal input to the MCU microcontroller 1, and the enabling terminal 301 of the power supply module 3 is connected to a GPIO pin 102 of the MCU microcontroller 1 to control the power supply The opening and closing of the module 3, the fan 4 is electrically connected to the power module 3, the fan 4 is provided with a fan status output terminal 401 and a speed control signal input terminal 402, and the fan status output terminal 401 is connected to the TIMER1 pin 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com