Preassembling equipment for button of automobile control panel and control method thereof

An automotive control and control panel technology, applied in metal processing equipment, manufacturing tools, metal processing and other directions, can solve the problems of inability to perform automatic pressing effect detection, no two-dimensional code scanning, low assembly efficiency, etc., and achieve operation control methods. Simple and efficient, guarantee the effect of pressing and guarantee the traceable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Such as figure 1 As shown, a kind of pre-assembly equipment for automobile control panel buttons includes a machine platform, the machine platform includes a machine base 7 and a bracket fixedly installed on the machine base 7, and a press-fitting device 30 is installed on the bracket. The first assembly platform 10 and the second assembly platform 20 are also fixedly installed on the machine base 7 , the installation position of the second assembly platform 20 corresponds to the installation position of the bracket, so that the press-fitting device 30 is located above the second assembly platform 20 .

[0036] The first assembly station 10 is located in front of the second assembly station 20 . The first assembly platform 10 includes a first assembly platform bottom plate 11 , and a first positioning post 13 , a first baffle plate 15 and a top block 12 are arranged on the first assembly platform bottom plate 11 . The first positioning column 13 can pass through two th...

Embodiment 2

[0047] On the basis of the above embodiments, the difference of this embodiment is that both the first baffle 15 and the second baffle 27 are controlled by air cylinders. A first position sensor 14 is provided on the bottom plate 11 of the first assembly platform. When the automobile control panel on the first assembly platform 10 is placed in place, the first position sensor 14 senses a signal and transmits it to the industrial control system. The cylinder connected to the first baffle 15 acts, and the first baffle 15 locks the vehicle control panel. Similarly, a second position sensor 24 is fixedly installed on the positioning seat 22 of the second assembly platform 20. After the automobile control panel on the positioning seat 22 is placed in place, the second position sensor 24 senses a signal and transmits it to the industrial control system. , the industrial control system controls the action of the cylinder connected to the second baffle 25, and the second baffle 25 loc...

Embodiment 3

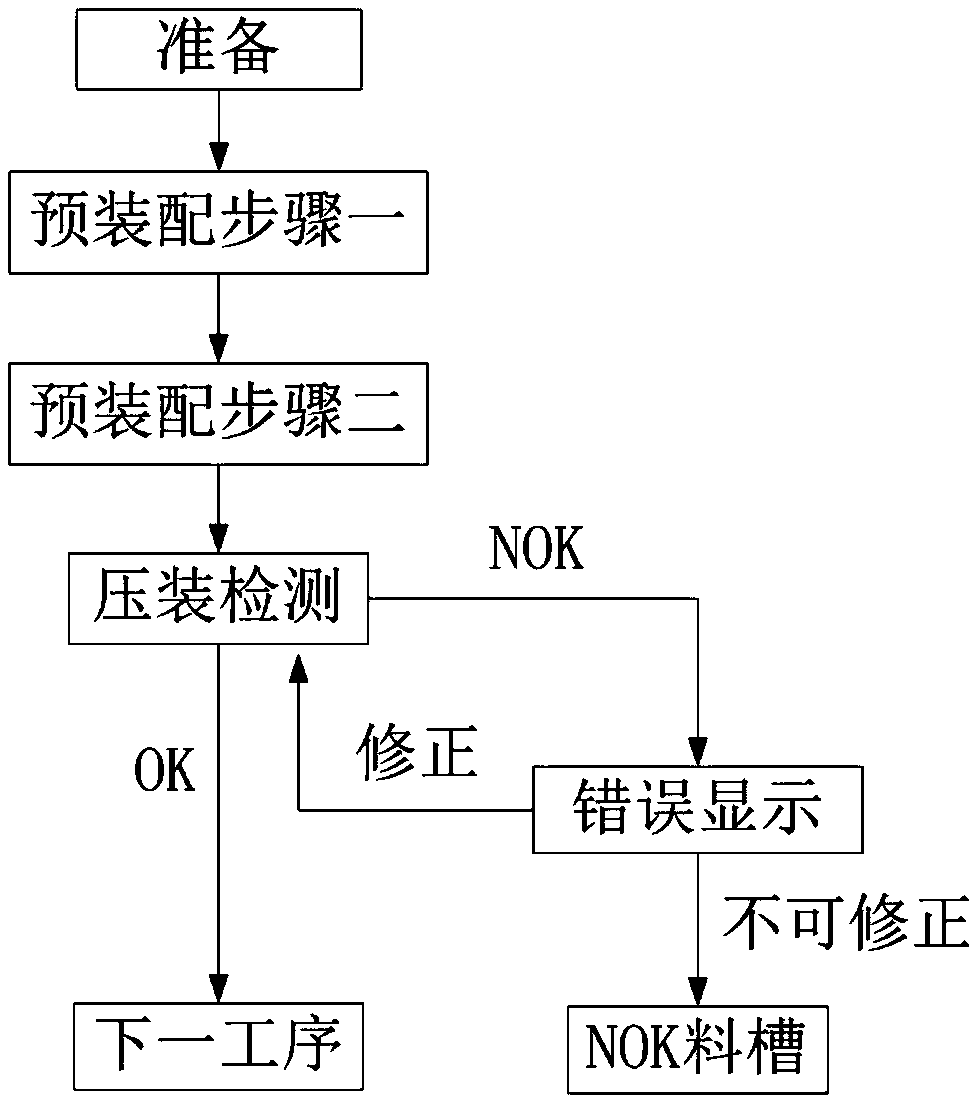

[0050] Such as image 3 As shown, a method for controlling a pre-assembled device of an automobile control panel button includes a boot preparation process and an assembly detection step. The start-up preparation process is: start the equipment, configure the parameters correctly, and make the equipment in the working standby state. Then start the following assembly inspection steps:

[0051] S100: Place the lower assembly of the first group of buttons on the predetermined position of the first assembly platform 10, then place the control panel housing on the first assembly platform 10, fix it with the first baffle plate 15, and collect the control panel housing The logo containing the identity information of the product, and finally the upper assembly of the first group of buttons is assembled with the lower assembly of the first group of buttons and the control panel housing;

[0052] S200: Take out the control panel casing, turn it over and put it into the second assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com