Steel pipe cutting device

A technology for cutting devices and steel pipes, applied in the direction of pipe shearing devices, shearing devices, and accessories of shearing machines, etc., can solve problems such as low efficiency and troublesome operation, and achieve the effects of convenient operation, simple structure, and improved cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

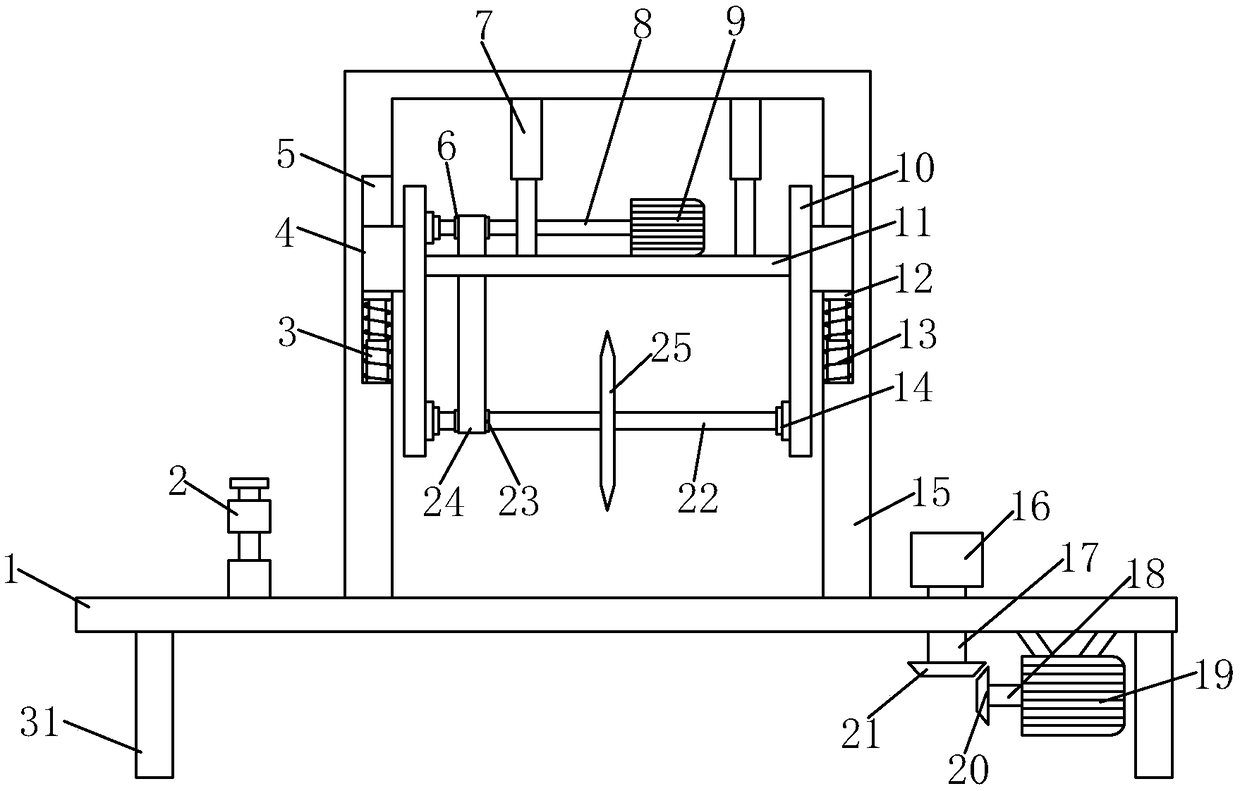

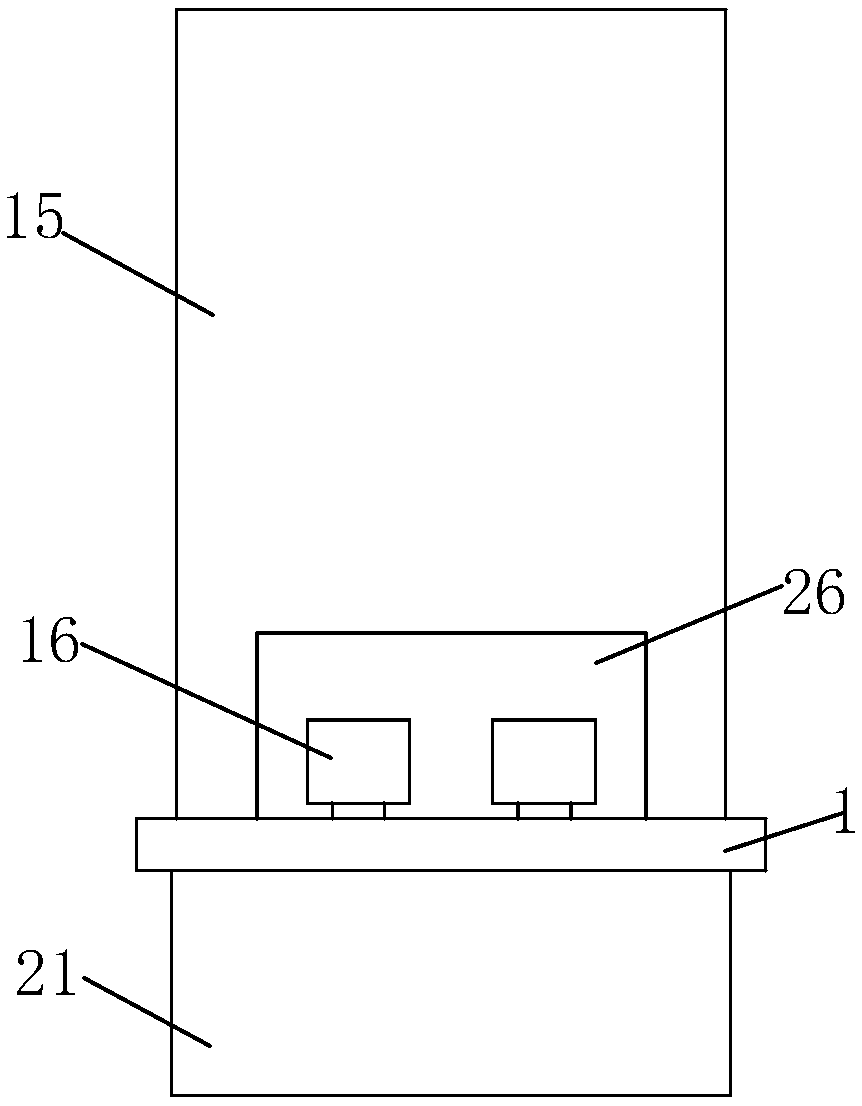

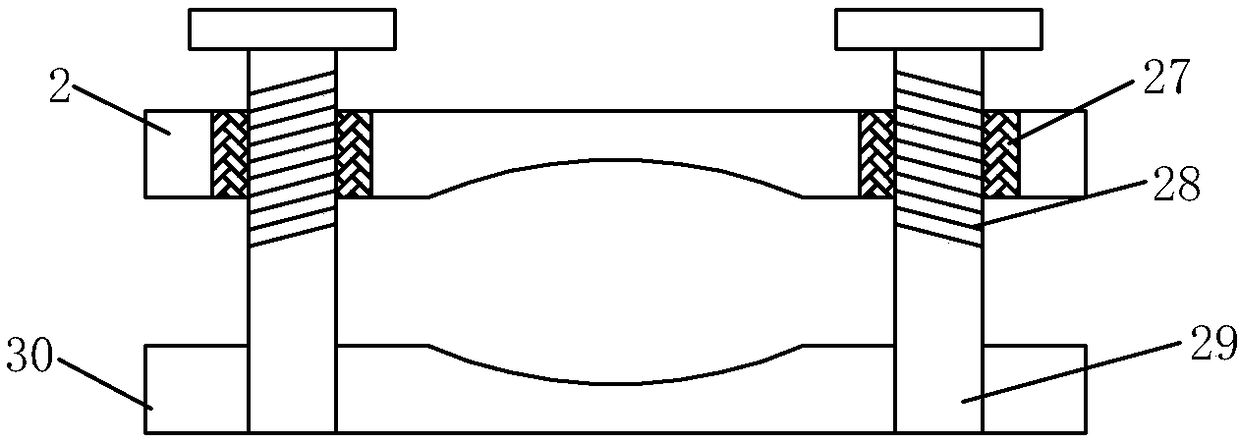

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0018] refer to Figure 1-3 , a steel pipe cutting device, including a base 1, the material of the base 1 is hard alloy steel, the strength is extremely high and the stress resistance is excellent, and it can bear heavy steel pipes, and the lower end of the base 1 is fixedly installed on both sides with support plates 31 A second AC asynchronous motor 19 is fixedly installed on one side of the lower end of the base 1 between the support plates 31, the model of the second AC asynchronous motor 19 is a YEJ-100L three-phase asynchronous motor, and the second AC asynchronous motor 19 is provided with a power control switch , and the second AC asynchronous motor 19 is ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com